Production system of silicon substrate liquid crystal display screen and production method thereof

A silicon-based liquid crystal and production system technology, applied in the direction of optics, instruments, electrical components, etc., can solve the problems of silicon wafer and glass deformation, expensive process equipment, difficult alignment film thickness, etc., to improve assembly quality, reduce costs, The effect of reducing the degree of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

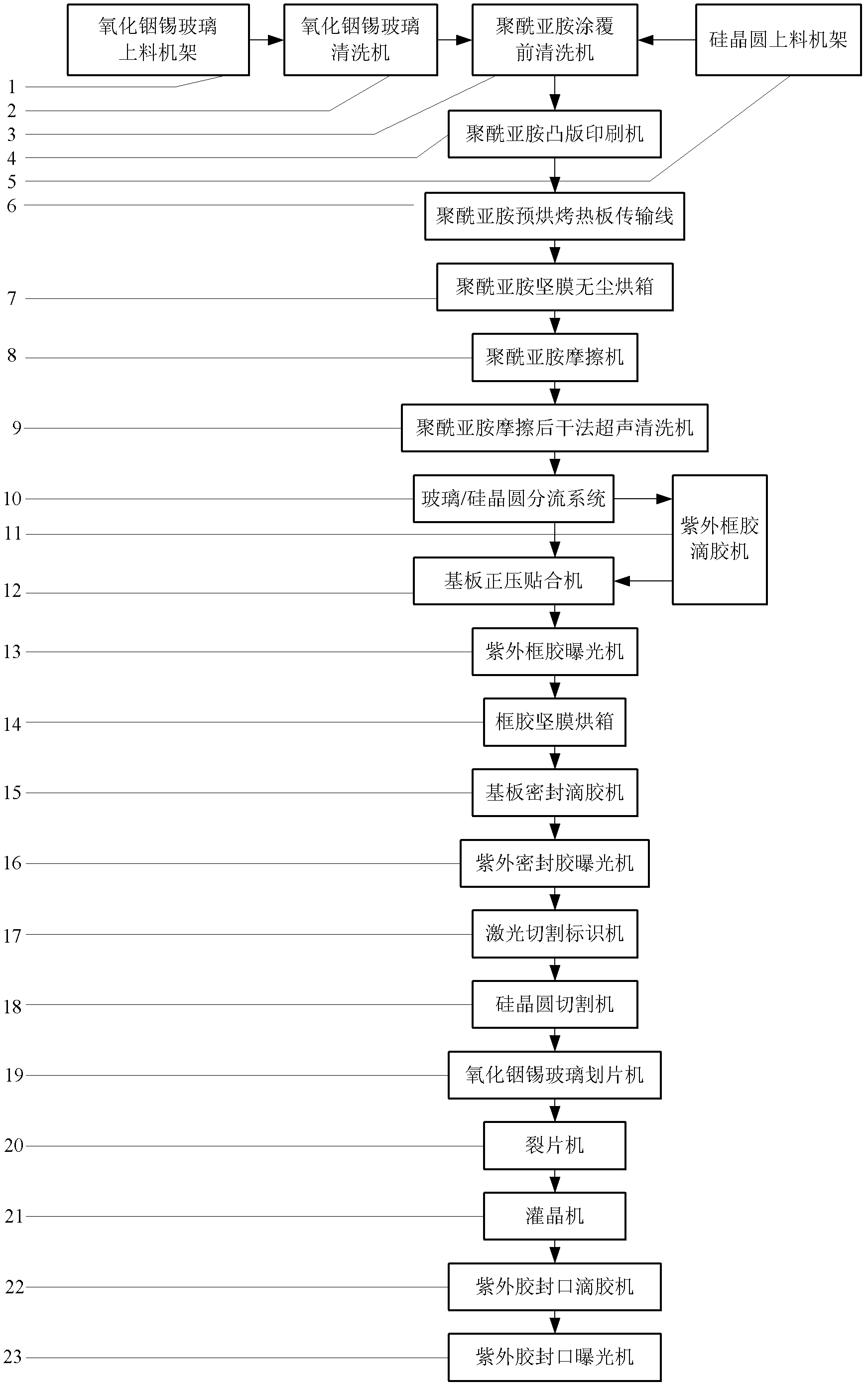

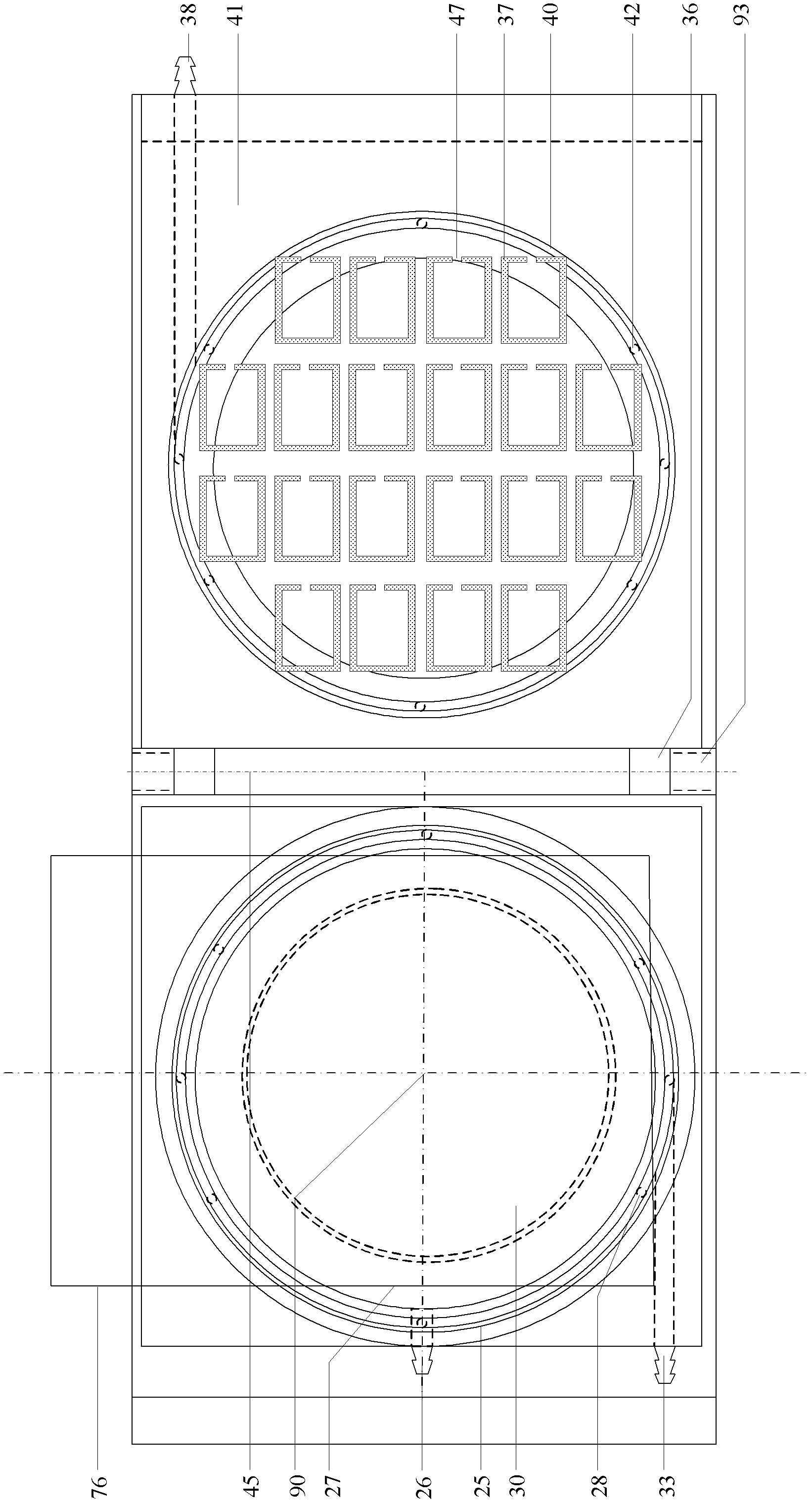

[0063] (1) Substrate cleaning step: the indium tin oxide glass 40 is initially cleaned in the indium tin oxide glass cleaning machine 2, and at least one piece of the indium tin oxide glass 40 that has undergone preliminary cleaning is alternated with at least one piece of the silicon wafer 24 Transported into the cleaning machine 3 before the polyimide coating to complete the cleaning; (2) the cleaned indium tin oxide glass 40 and the silicon wafer 24 are sequentially coated, dried, rubbed, and dry ultrasonically cleaned; Covering polyimide film is carried out in polyimide letterpress printing machine 4, drying can be carried out in polyimide hard film dust-free oven 7, rubbing polyimide film is carried out in polyimide rubbing machine 8 The dry ultrasonic cleaning of the polyimide film is carried out in a dry ultrasonic cleaning machine 9; the thickness of the polyimide film coated on at least one piece of indium tin oxide glass and at least one piece of the silicon wafer is ...

Embodiment 2

[0072] (1) Substrate cleaning step: the indium tin oxide glass 40 is initially cleaned in the indium tin oxide glass cleaning machine 2, and at least one piece of the indium tin oxide glass 40 that has undergone preliminary cleaning is alternated with at least one piece of the silicon wafer 24 Transported into the cleaning machine 3 before the polyimide coating to complete the cleaning; (2) the cleaned indium tin oxide glass 40 and the silicon wafer 24 are sequentially coated, dried, rubbed, and dry ultrasonically cleaned; Covering polyimide film is carried out in polyimide letterpress printing machine 4, drying can be carried out in polyimide hard film dust-free oven 7, rubbing polyimide film is carried out in polyimide rubbing machine 8 The dry ultrasonic cleaning of the polyimide film is carried out in a dry ultrasonic cleaning machine 9; the thickness of the polyimide film coated on at least one piece of indium tin oxide glass and at least one piece of the silicon wafer is ...

Embodiment 3

[0081] (1) Substrate cleaning step: the indium tin oxide glass 40 is initially cleaned in the indium tin oxide glass cleaning machine 2, and at least one piece of the indium tin oxide glass 40 that has undergone preliminary cleaning is alternated with at least one piece of the silicon wafer 24 Transported into the cleaning machine 3 before the polyimide coating to complete the cleaning; (2) the cleaned indium tin oxide glass 40 and the silicon wafer 24 are sequentially coated, dried, rubbed, and dry ultrasonically cleaned; Covering polyimide film is carried out in polyimide letterpress printing machine 4, drying can be carried out in polyimide hard film dust-free oven 7, rubbing polyimide film is carried out in polyimide rubbing machine 8 The dry ultrasonic cleaning of the polyimide film is carried out in a dry ultrasonic cleaning machine 9; the thickness of the polyimide film coated on at least one piece of indium tin oxide glass and at least one piece of the silicon wafer is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com