Modified barbadosnut dreg adhesive and preparation method thereof

A technology of jatropha sap and adhesive, applied in the direction of adhesive, adhesive type, graft polymer adhesive, etc., can solve the problems of high curing temperature, low solid content, slow curing speed, etc., and achieve low curing temperature. , High solid content, the effect of reducing the curing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

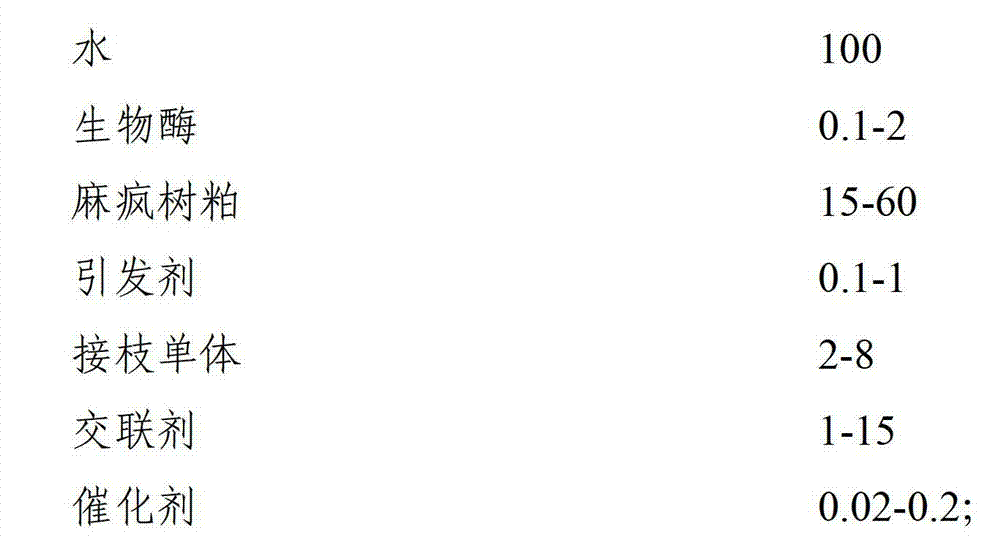

[0033] 1. Prepare materials according to the following weight ratio (Kg):

[0034]

[0035] 2. Add all the above-mentioned raw materials into the reaction kettle, stir evenly, and prepare the Jatropha curcas meal solution;

[0036] 3. Adjust the pH value of the solution to 5.0, react at 50°C for 30 minutes, then raise the temperature to 90°C, and completely inactivate the biological enzyme;

[0037] 4. Add 3Kg of grafted monomer PEGDMA and 0.1Kg of ammonium persulfate initiator to react for 50min, set aside;

[0038] 5. Add 1Kg cross-linking agent HMDI and 0.05Kg catalyst stannous octoate and mix well before use.

[0039] The quality indicators of the prepared adhesives are shown in Table 1.

[0040] The performance index of adhesive of the present invention in table 1

[0041]

Embodiment 2

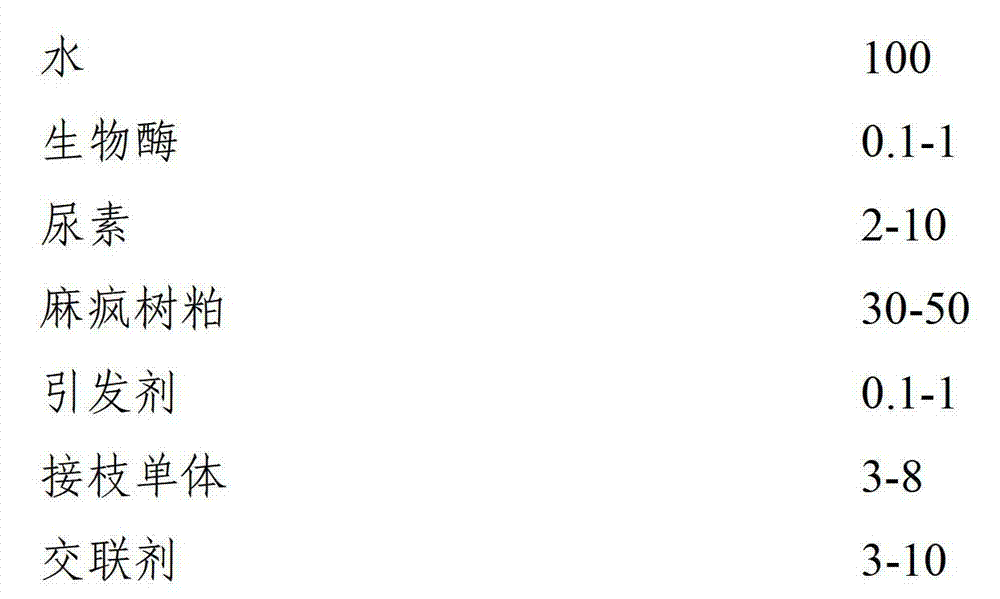

[0043] 1. Prepare materials according to the following weight ratio (Kg):

[0044]

[0045] 2. Add all the above-mentioned raw materials into the reaction kettle, stir evenly, and prepare the Jatropha curcas meal solution;

[0046] 3. Adjust the pH value of the solution to 5.0, react at 50°C for 60 minutes, then raise the temperature to 90°C, and completely inactivate the biological enzyme;

[0047] 4. Add 5Kg of grafted monomer acrylamide and 0.2Kg of potassium persulfate initiator to react for 50min, set aside;

[0048] 5. Add 10Kg cross-linking agent PAPI and 0.05Kg catalyst stannous octoate and mix well before use.

[0049] The quality indicators of the prepared adhesives are shown in Table 2.

[0050] The performance index of table 2 adhesive of the present invention

[0051]

Embodiment 3

[0053] 1. Prepare materials according to the following weight ratio (Kg):

[0054]

[0055] 2. Add all the above-mentioned raw materials into the reaction kettle, stir evenly, and prepare the Jatropha curcas meal solution;

[0056]3. Adjust the pH value of the solution to 7.0, react at 30°C for 70 minutes, then raise the temperature to 90°C, and completely inactivate the biological enzyme;

[0057] 4. Add 8Kg of graft monomer 2,3-epoxypropyl methacrylate and 0.1Kg of initiator cerium ammonium nitrate to react for 50min, set aside;

[0058] 5. Add 8Kg cross-linking agent PAPI and 0.15Kg catalyst dibutyltin dilaurate and mix well before use.

[0059] The quality indicators of the prepared adhesives are shown in Table 3.

[0060] The performance index of adhesive of the present invention of table 3

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com