Stable type double-layer ground-heating solid wood floorboard and method for manufacturing same

A technology for solid wood flooring and a manufacturing method, which is applied in the directions of manufacturing tools, building structures, wood processing appliances, etc., can solve problems such as tile deformation, and achieve the effects of good flatness, improved yield and output, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] a. Manufacturing steps of veneer and base material: Saw the hard broad-leaved oak wood into a 2.2mm thick veneer, and saw the fast-growing masson pine into a 17.5mm thick base material.

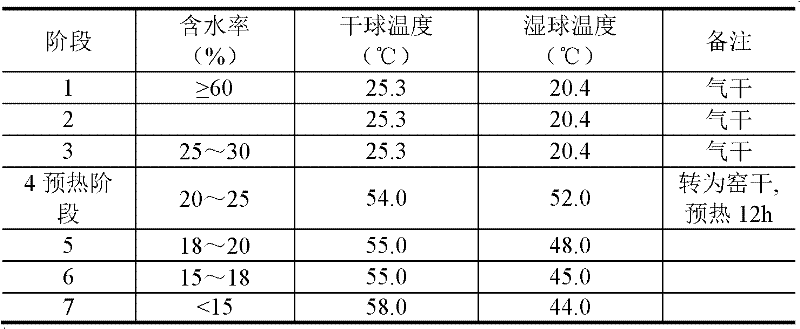

[0036] b. Drying step: stack 5 pieces of oak veneer with a thickness of 2.2 mm together to form a stack, use pallets with uniform specifications and aluminum alloy spacers, and the distance between the spacers and the end face of oak veneer during stacking is within 5cm, and the distance between the spacers The spacing is 20cm, and the spacers are neatly formed into a straight line in the straight direction. Cement blocks are pressed on the stacked oak veneer, and placed in an air-drying shed for air-drying first (the average day-night temperature is 25.3°C, and the day-night average wind speed 2.1m / s, the season is September), and when the moisture content of the oak veneer is reduced to about 25%, it is then moved to a drying kiln for kiln drying, so that the moisture content of the v...

Embodiment 2

[0047] a. Manufacturing steps of veneer and substrate: Saw the hard broad-leaved ash ash to make a 3.6mm thick veneer, and saw the fast-growing sylvestris sylvestris pine to make a 12.8mm thick substrate.

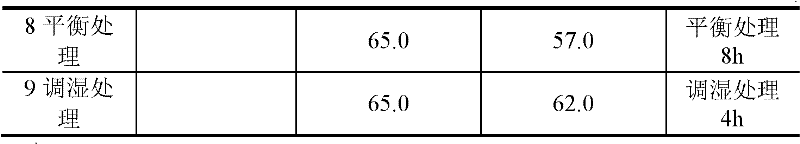

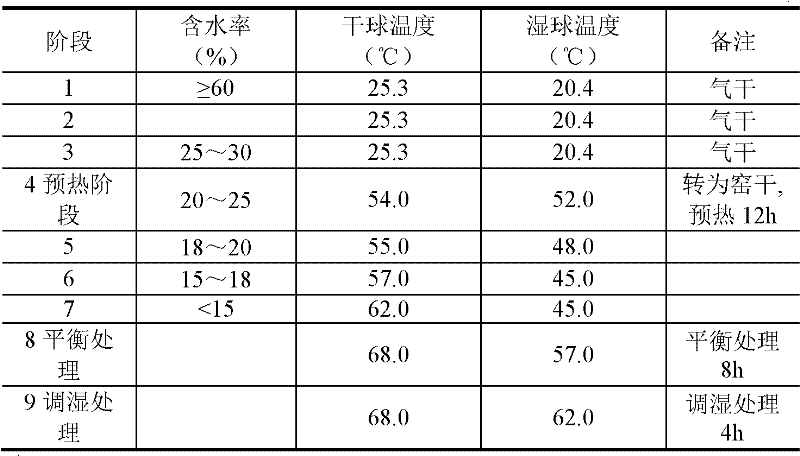

[0048] b. Drying step: stack 2 pieces of 3.6mm thick ash veneer together to form a stack, use trays with uniform specifications and aluminum alloy spacers, and when stacking, the distance between the spacers and the end face of the ash veneer is within 5cm. The distance between the strips is 20cm, and the strips are neatly formed into a straight line in the straight direction. Cement blocks are pressed on the stacked mandshurica veneer, and placed in a drying kiln to dry, so that the moisture content of the veneer is ≤15%. According to the same drying procedure, stack 3 pieces of 12.8mm thick sylvestris pine base materials together to form a whole stack, use trays with uniform specifications and aluminum alloy spacers, and the distance between the spacers and the end surface...

Embodiment 3

[0054] a. Manufacturing steps of veneer and base material: Saw the hard broad-leaved maple wood into a veneer with a thickness of 2.8 mm, and saw the fast-growing poplar wood into a base material with a thickness of 13.4 mm.

[0055] b. Drying step: stack 4 pieces of maple veneer with a thickness of 2.8mm together to form a stack, using trays with uniform specifications and aluminum alloy spacers. The spacing is 20cm, and the spacers are neatly formed into a straight line in the vertical direction. Cement blocks are pressed on the stacked maple veneer, and placed in a drying kiln to dry, so that the moisture content of the veneer is ≤15%. According to the same drying procedure, three pieces of 13.4mm thick poplar wood substrates are stacked together to form a whole stack, using trays with uniform specifications and aluminum alloy spacers. 10-20cm, the spacers are neatly arranged in a straight line in the vertical direction, and cement blocks are pressed on the stacked poplar b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com