flexible cooling pipe

A duct and heat sink technology, applied in the field of flexible heat radiating ducts, can solve the problems of uneven heat dissipation of the junction surface, not meeting the needs of industrial utilization, affecting the value of industrial utilization, etc., and achieving the effect of uniform heat dissipation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

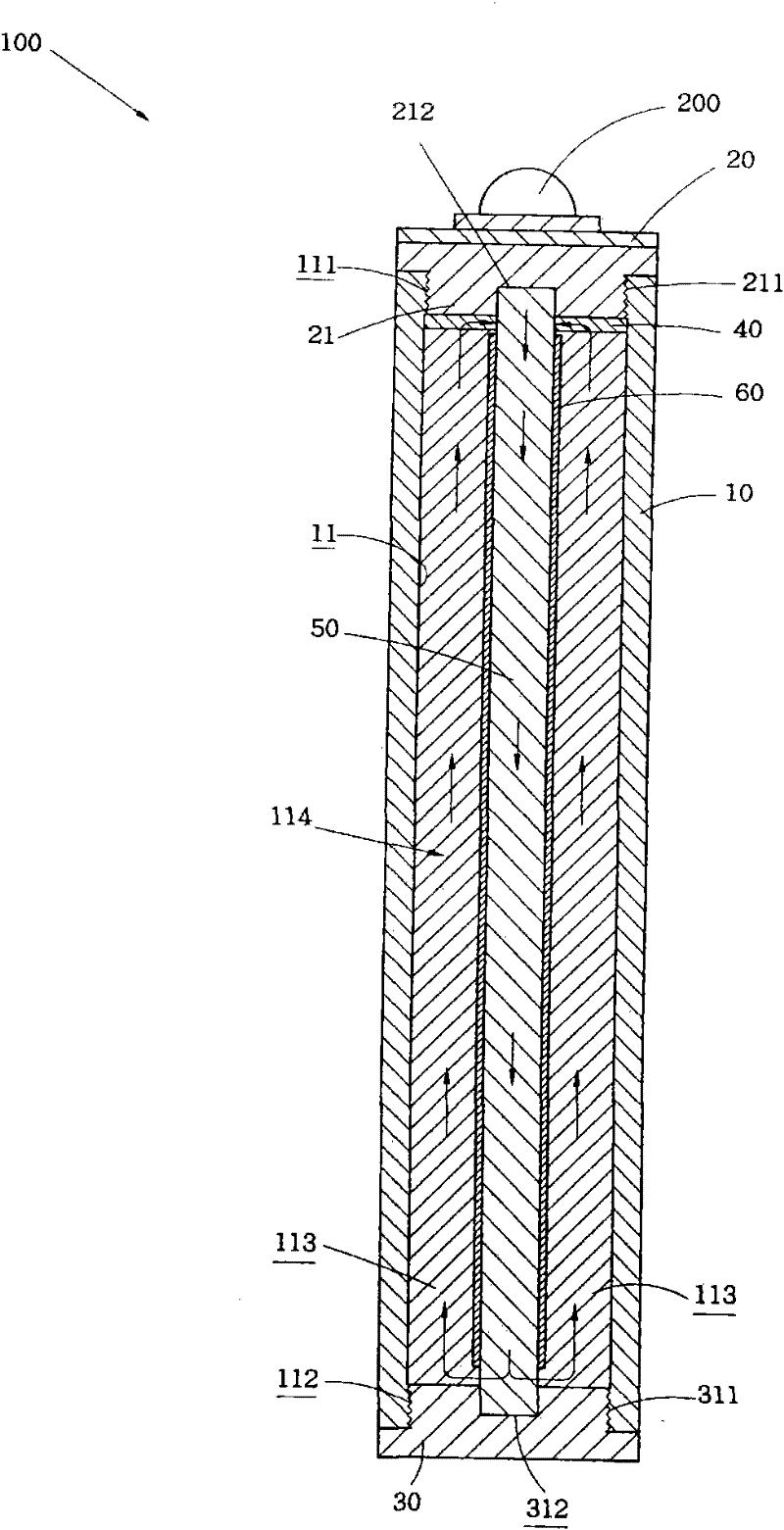

[0050] See figure 1 , figure 2 and image 3 Shown here is the first embodiment of the flexible heat dissipation pipe 100 of the present invention. The flexible heat dissipation pipe 100 includes an outer tube 10, which is a heat conductor and a flexible tube. For example: a soft silicone tube, which can be flexibly bent, the outer tube 10 forms at least one chamber 11, the inner wall of the upper end of the chamber 11 is provided with a plurality of locking screws 111, and the inner wall of the lower end of the chamber 11 is provided with A number of lock screws 112.

[0051] A heat-conducting element 20 is made of a heat-conducting material, such as metal materials such as aluminum, copper or alloy, and can be connected to an electronic load 200 on the external surface. The type of the electronic load 200 is not limited. In the present invention, a light-emitting diode lamp is used. As an example, the heat-conducting member 20 has a joint 21 formed on the inner edge, and a plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com