an alkaline battery

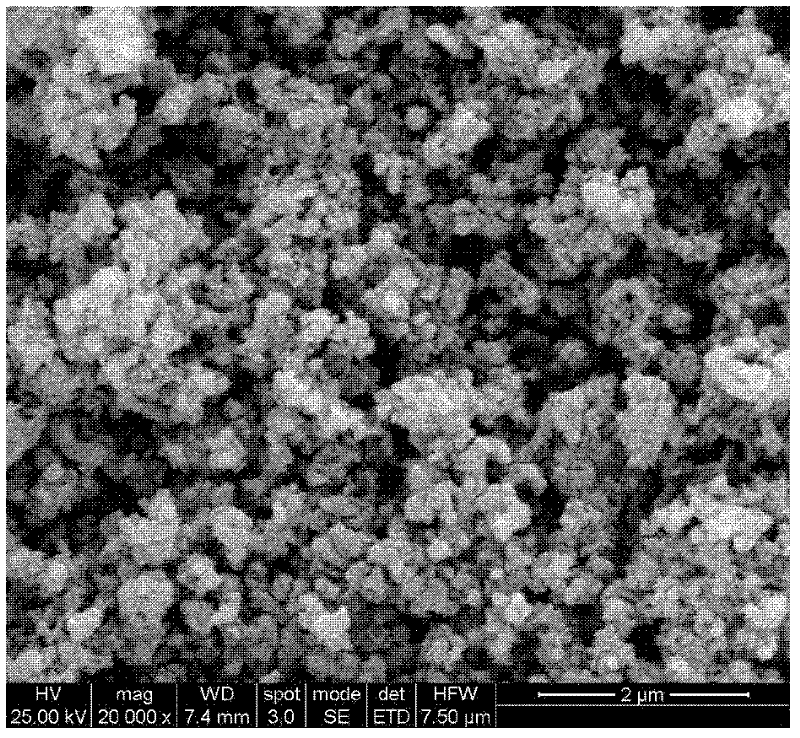

An alkaline battery and alkaline technology, applied in the manufacture of alkaline batteries, alkaline battery electrodes, alkaline batteries, etc., can solve the problems of particle agglomeration specific surface area, low reaction discharge capacity, large particle size, etc., and achieve specific surface area High, easy to handle, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

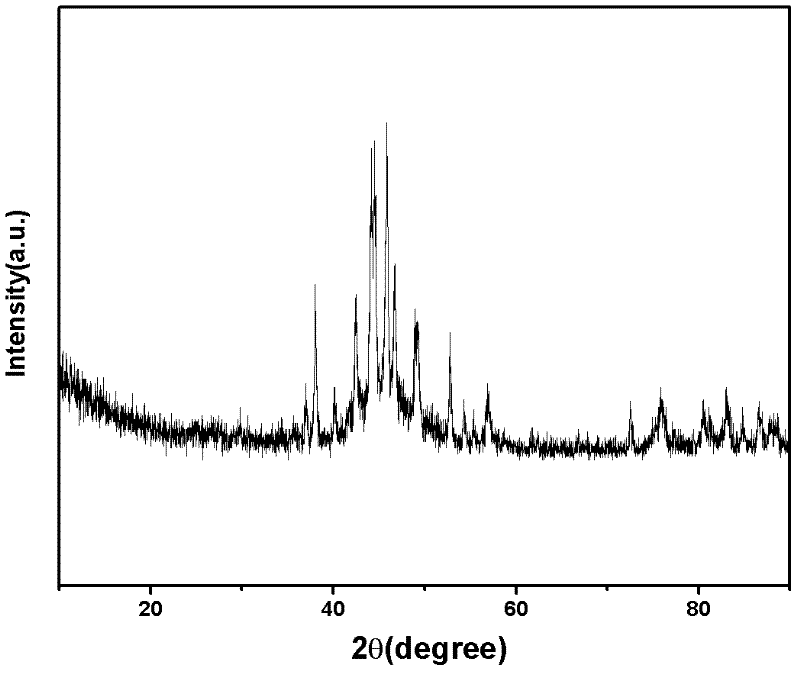

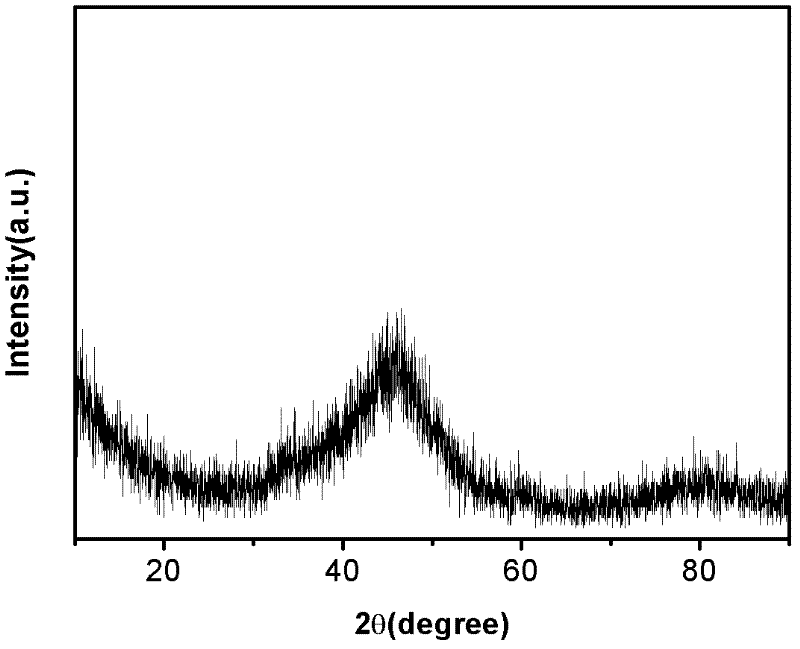

[0039] Place the reactor in an environment of 4°C, under the stirring condition of a magnetic stirrer, add 0.1mol / L, 100mL of CoCl 2 The solution was added to the reactor. Then, at a rate of 1 mL / min, add excess NaBH with NaOH to adjust the pH value to 12 dropwise. 4 Solution (0.5mol / L, 100mL), continued to stir for 0.5h after the dropwise addition to ensure complete reaction, and precipitate 1 was obtained. The obtained precipitate 1 was washed three times with deionized water and then suction-filtered to obtain precipitate 2. Put the precipitate 2 into a cold trap, drop to -90°C together with the cold trap, and freeze at -90°C for 3 hours at a cooling rate of 15°C / min. After freezing, vacuumize to sublimate the liquid in the sediment 2 to realize the drying process. Under the conditions of vacuum degree ≤ 10.0Pa (the vacuum degree can be maintained at ≤ 10.0Pa under the technical conditions of this experiment, the vacuum degree is constantly changing in the actual experim...

Embodiment 2

[0042] Place the reactor in an environment of 4°C, under the stirring condition of a magnetic stirrer, add 0.1mol / L, 100mL of CoCl 2 The solution was added to the reactor. Then, at a rate of 5 mL / min, add excess NaBH with NaOH to adjust the pH value to 12 dropwise. 4 solution (0.1mol / L, 100mL), continue to stir for 0.5h after the dropwise addition to ensure the completion of the reaction, drive away the hydrogen bubbles, and obtain precipitate 1. The obtained precipitate 1 was washed three times with deionized water and then suction-filtered to obtain precipitate 2. Put the precipitate 2 into a cold trap, drop to -90°C together with the cold trap, and freeze at -90°C for 3h. After freezing, vacuumize to sublimate the liquid in the sediment 2 to realize the drying process. Under the conditions of vacuum degree ≤ 10.0Pa (the vacuum degree can be kept at ≤ 10.0Pa under the technical conditions of this experiment, the vacuum degree is constantly changing in the actual experimen...

Embodiment 3

[0045] Place the reactor in an environment of -8°C, under the stirring condition of a magnetic stirrer, add 0.1mol / L, 100mL of CoCl 2 The solution was added to the reactor. Then, at a rate of 5 mL / min, add excess NaBH with ammonia water to adjust the pH value to 12 dropwise. 4 solution (0.5mol / L, 100mL), continue to stir for 0.5h after the dropwise addition to ensure the completion of the reaction, drive away the hydrogen bubbles, and obtain precipitate 1. The obtained precipitate 1 was washed three times with absolute ethanol and once with deionized water, and then suction-filtered to obtain precipitate 2, which was placed in a refrigerator at -4°C for 1 hour. The temperature of the cold trap was lowered to -90°C, and the precipitate 2 placed in the -4°C refrigerator for 1 hour was put into the cold trap, and frozen at -90°C for 6 hours. After freezing, vacuumize to sublimate the liquid in the sediment 2 to realize the drying process. Under the conditions of vacuum degree ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com