Rigid polyurethane foam insulation material with fireproof and anticorrosion function and preparation method thereof

A foam insulation material, rigid polyurethane technology, applied in building insulation materials, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of poor insulation, fire resistance, flame resistance and other problems, and achieve long flame resistance time, flame retardant permeability, coating thin layer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

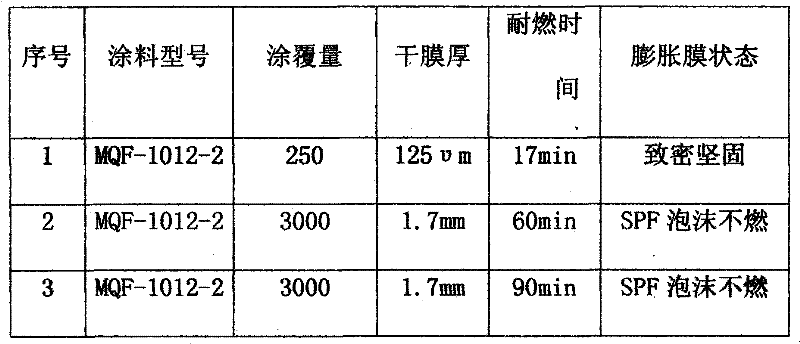

[0010] A rigid polyurethane foam insulation material with fireproof and anticorrosion function, 20-30 parts of modified high-chlorinated polyethylene is melted into a 30% solution under high-speed stirring, and 10-15 parts of acrylic resin and epoxy resin are mixed : Add 4-5 parts, add 1-2 parts of organic expansive soil under low-speed stirring, and stir for about ten minutes; then add 2-5 parts of melamine, 6-10 parts of pentaerythritol, 6-10 parts of zinc aluminate, 13 - 15 parts of ammonium polyphosphate, 2-6 parts of chlorinated paraffin, 2-6 parts of titanium dioxide, 4-8 parts of flame retardant, etc., after stirring for 30 minutes, send it to the grinder for grinding, and stop grinding after the detection fineness reaches 90μm; Add 1-2 parts of defoamer under stirring, and add all the remaining 10-15 parts of solvent and stir evenly. Apply the prepared fire-proof intermediate to the base material that has been sprayed with a penetrating primer on the rigid polyurethane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com