Method for growing blue ceramic film layer in situ on the surface of aluminum alloy and aluminum matrix composite material

An aluminum-based composite material, in-situ growth technology, applied in the direction of anodization, etc., can solve the problems of blue ceramic film layer that cannot be uniform in color, rapid failure of electrolyte, and inability to be used repeatedly, and achieves stable electrolyte. High wear resistance and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

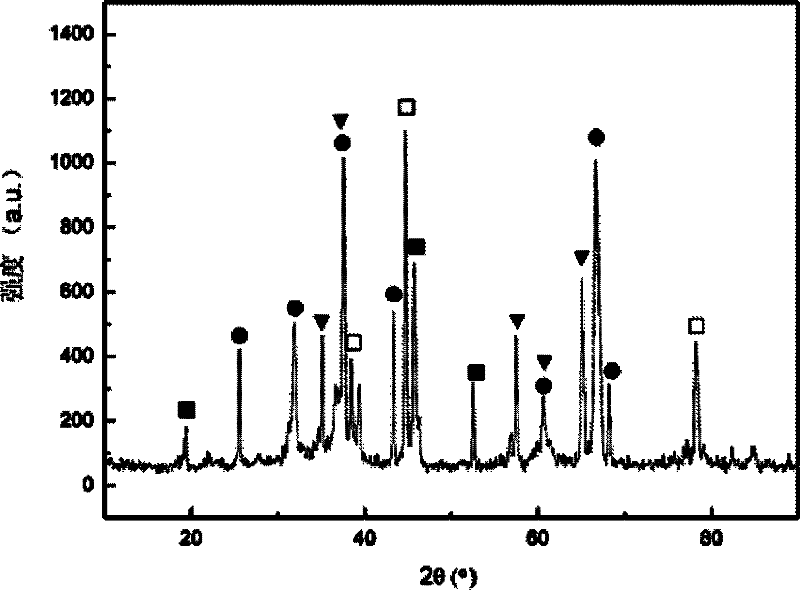

Image

Examples

specific Embodiment approach 1

[0016] Specific Embodiment 1: This embodiment is a method for in-situ growth of a blue ceramic film on the surface of an aluminum alloy and an aluminum-based composite material, which is achieved through the following steps: 1. Clean the surface of the aluminum substrate to remove surface oil and impurities, The aluminum substrate is an aluminum alloy or an aluminum-based composite material; 2. Prepare the electrolyte: the concentration of the main film-forming agent is 1g / L-50g / L, the concentration of the coloring additive is 1g / L-50g / L, and the auxiliary film-forming The concentration of the agent is 0g / L-40g / L and the concentration of the complexing agent is 0g / L-20g / L. Weigh the main film-forming agent, coloring additive, auxiliary film-forming agent, complexing agent and water respectively to prepare the electrolyte. Wherein, the main film-forming agent is one or a combination of phosphoric acid, sulfuric acid and citric acid, and the coloring additive is an inorganic or o...

specific Embodiment approach 2

[0020] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the specific method for cleaning the surface of the aluminum substrate in step 1 is: place the aluminum substrate in ethanol or acetone, and clean and remove the oil and impurities on the surface of the aluminum substrate , and then polished to remove the oxide film. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0021] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the aluminum substrate in step one is an aluminum alloy with a grade of LY12, LF3, LD11, LC4, Zl101 or L3, or is made of silicon carbide or aluminum borate , Magnesium borate or alumina as reinforcement reinforced aluminum matrix composites. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com