A kind of preparation method of hollow structure coating cathode material

A positive electrode material and hollow structure technology, applied in structural parts, battery electrodes, electrical components, etc., can solve the problems of poor battery cycle performance, low utilization rate of electrode active materials, accelerated lithium corrosion, etc., to improve cycle performance and increase capacity Retention rate and the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0026] A method for preparing a hollow structure coated positive electrode material, comprising the steps of:

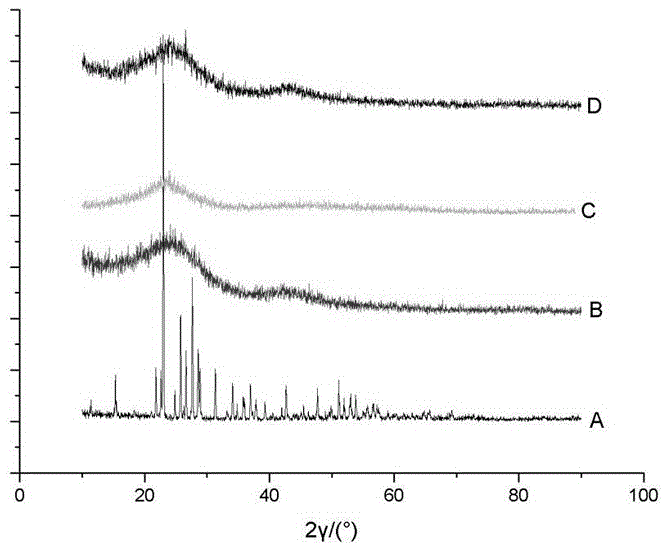

[0027] 1) Preparation of C / S composites

[0028] Grind activated carbon (analytical pure) and elemental sulfur (analytical pure) in a ball mill evenly in a mass ratio of 1:1, put them in a vacuum drying oven, and flush with argon for about 20 minutes to remove the air inside and avoid high temperature. Sulfur is oxidized. Then, under a flowing nitrogen atmosphere, heat the mixture of activated carbon and elemental sulfur to 155°C and keep it at this temperature for 10 hours, then raise the temperature to about 250°C and keep it at this temperature for 3 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com