Continuous fiber enhanced thermoplastic antiflaming presoaking belt composite material and preparation method thereof

A technology for reinforcing thermoplastic and continuous fibers, which is applied in the field of continuous fiber-reinforced thermoplastic flame-retardant prepreg composite materials and their preparation, and achieves the effects of good impact resistance, high flame retardancy and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Resin is prepared by following raw material parts by weight:

[0045] PP65

[0046] Decabromodiphenylethane 24

[0047] Sb 2 o 3 8

[0048] PP-g-MAH 3

[0049] Glass beads 5

[0050] Antioxidant 1010 0.4

[0051] Antioxidant 168 0.2

[0052] Light stabilizer 3346 0.3

[0053] Light stabilizer 3853S 0.3

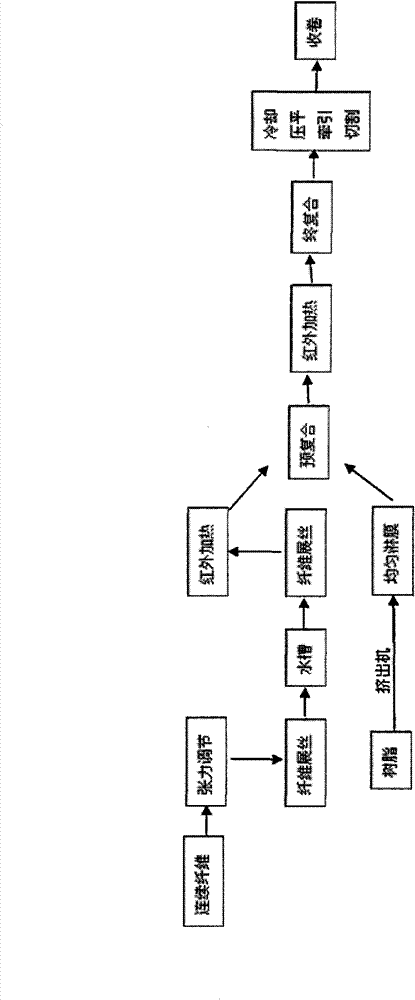

[0055] Such as figure 1 As shown, thermoplastics, flame retardants, grafting agents, glass beads and auxiliary additives are mixed uniformly by a high mixer and then extruded in a twin-screw extruder for granulation. 45%). The fibers treated with sizing agent (accounting for 55% of the total amount of prepreg tape) are introduced into the fiber spreading system through the spinning creel, and the tension of the system is adjusted through the tension adjustment system, so that each fiber bundle is evenly stressed, so that it can be flattened prepreg tape. The flat prepreg belt passes through a spreadi...

Embodiment 2~4

[0060] Carry out according to the processing route of embodiment 1, raw material proportioning is configured by following weight parts:

[0061]

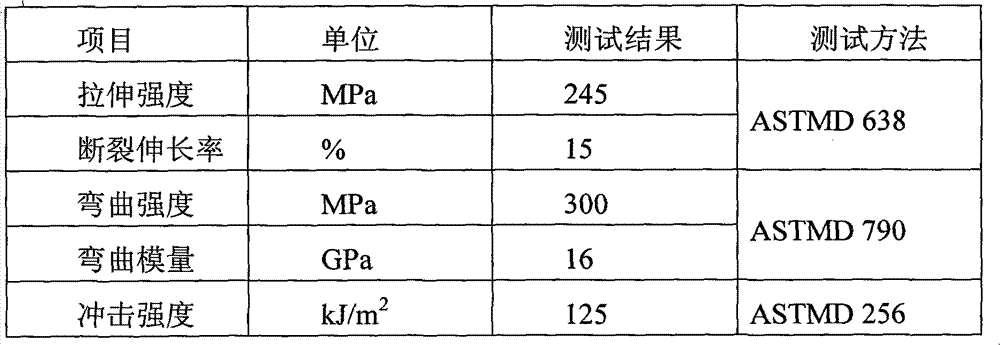

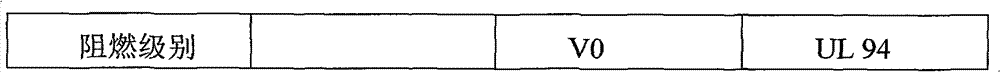

[0062] Gained product performance is as follows table:

[0063]

Embodiment 5

[0065] A preparation method of continuous fiber reinforced thermoplastic flame-retardant prepreg tape composite material, the method comprises the following steps:

[0066] (1) Preparation of modified resin, prepare raw materials according to the following components and parts by weight:

[0067] Polyethylene 55,

[0068] Decabromodiphenylethane 35,

[0069] The weight ratio of antimony trioxide is 5,

[0070] Polypropylene grafted maleic anhydride (PP-g-MAH) 3,

[0071] Glass beads with a particle size of 2-130 μm and a true density of 0.25-0.6 g / cm3 8,

[0072] Antioxidant 1010 0.1

[0073] Antioxidant 168 0.2,

[0074] Commercially available light stabilizer 0.6,

[0075] Ethylene bisstearamide 1;

[0076] The above raw materials are mixed uniformly by a high-speed mixer, and then extruded and granulated in a twin-screw extruder to obtain a modified resin;

[0077] (2) Weighing the modified resin prepared in step (1) by 45wt%, continuous fiber 55wt%; the continuous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com