A kind of three-dimensional carbon nanotube nanocomposite catalyst and its preparation method and application

A nanocomposite and carbon nanotube technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as desorption, incomplete adsorption, secondary pollution, etc., and achieve high adsorption capacity , complete degradation and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the three-dimensional carbon nanotube nanocomposite catalyst is carried out as follows:

[0024] 1) Dissolving the cadmium sulfide nanoparticles in an organic solvent including chloroform, n-hexane, tetrahydrofuran, toluene or ethyl acetate to prepare a solution with a mass volume concentration of 0.01-2 mg / mL;

[0025] 2) soaking the carbon nanotube sponge in a solution of cadmium sulfide nanoparticles, the mass ratio of carbon nanotubes and cadmium sulfide nanoparticles is 1-200:1, and soaking for 0.5-24 hours at a temperature of 0-50°C; The cadmium sulfide nanoparticles are attached to the surface of the carbon nanotube sponge and inside the pores of the carbon nanotube sponge to form a three-dimensional carbon nanotube nanocomposite catalyst;

[0026] 3) Take out the three-dimensional carbon nanotube nanocomposite catalyst and dry it in vacuum.

[0027] The application of the three-dimensional carbon nanotube nanocomposite catalyst as a ph...

Embodiment 1

[0041] Preparation of three-dimensional carbon nanotube nanocomposite catalyst:

[0042] Take the density as 7.3mg / cm 33.8 mg of carbon nanotube sponge was immersed in 3 mL of toluene solution with a concentration of 1 mg / mL cadmium sulfide nanoparticles at room temperature, soaked for 24 hours and taken out. After vacuum drying, a three-dimensional block product was obtained. The mass ratio of carbon nanotube sponge to cadmium sulfide is 2:1. Observed by a scanning electron microscope (model Hitachi S4800 FESEM), the cadmium sulfide nanoparticles are located on the surface and inside the pores of the carbon nanotube sponge. The particle size of the cadmium sulfide nanoparticles was measured by a transmission electron microscope (type Tecnai T20) to be 4-6 nm.

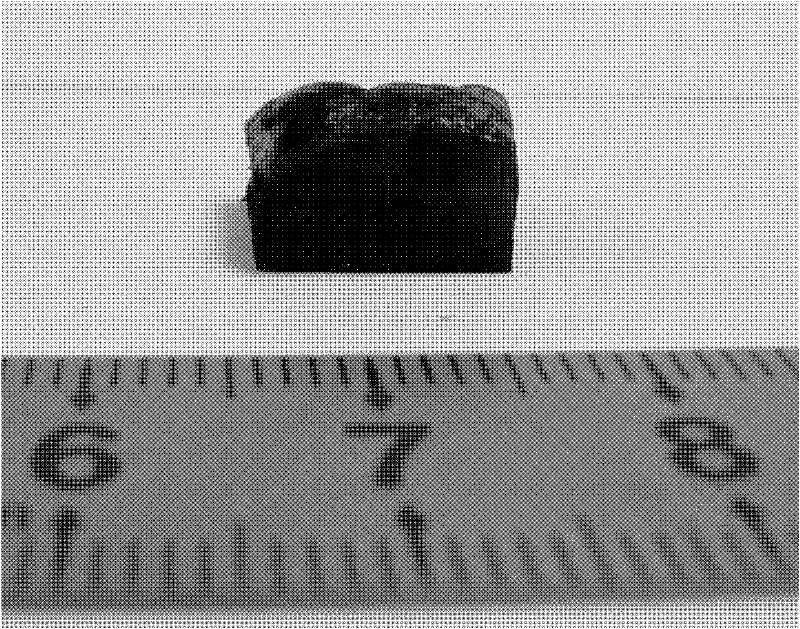

[0043] The photo of the three-dimensional carbon nanotube nanocomposite catalyst prepared by the present embodiment is as follows figure 1 shown. The scanning electron micrograph of the three-dimensional carbon na...

Embodiment 2

[0045] Preparation of three-dimensional carbon nanotube nanocomposite catalyst:

[0046] Take the density as 5.8mg / cm 3 Immerse 3.8 mg of carbon nanotube sponge in 3 mL of chloroform solution with a concentration of 0.01 mg / mL cadmium sulfide nanoparticles at 0° C., soak for 0.5 h and take it out. After vacuum drying, a three-dimensional block product was obtained. The mass ratio of carbon nanotube sponge to cadmium sulfide is 200:1. Observed by a scanning electron microscope (model Hitachi S4800FESEM), the cadmium sulfide nanoparticles are located on the surface and inside the pores of the carbon nanotube sponge. The particle size of the cadmium sulfide nanoparticles was measured by a transmission electron microscope (type: Tecnai T20) to be 3-5 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com