A heat-conducting aluminum nitride insulating metal substrate and its preparation method

A metal substrate and insulating metal technology, which is applied in circuit substrate materials, printed circuit manufacturing, printed circuit components, etc., can solve the problem of high manufacturing cost, limited application scope of thermally conductive metal substrates, and complicated preparation methods of aluminum nitride insulating films, etc. problem, to achieve the effect of long service life, production process and easy operation, high performance reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

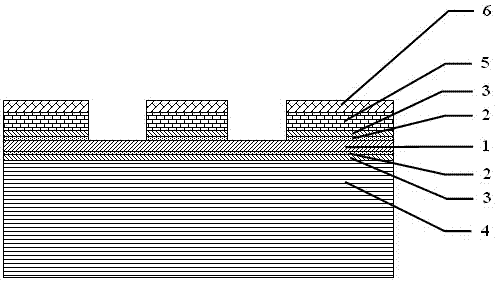

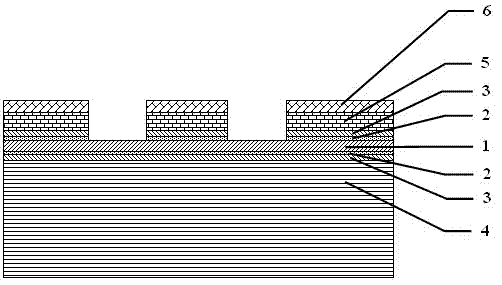

Embodiment 1

[0029] On both surfaces of a 0.2mm thick aluminum nitride ceramic plate, a buffer layer - molybdenum and titanium alloy 300 ?, and then magnetron sputtering metal silver 800 ? The surface is electroplated with copper 1mm, and the surface of the other metal silver is electroplated with silver-copper alloy 10μm, the conductive layer is thickened, and the thermal conductivity of the test is 136W / m·K. Then stick a film on the surface of the metal gold plating layer, etch to obtain the required circuit; finally perform electroless silver plating of 15 μm to obtain an aluminum nitride insulating metal substrate with high thermal conductivity.

Embodiment 2

[0031] On both surfaces of the 0.3mm thick aluminum nitride ceramic plate, a layer of buffer layer is magnetron sputtered - tungsten and titanium alloy 500 ? The copper surface is electroplated with 0.8mm of nickel-copper alloy, and the other side of the metal copper surface is chemically plated with 10μm of silver to thicken the conductive layer. The measured thermal conductivity is 121W / m·K. Then, stick a film on the surface of the metal silver plating, etch to obtain the required circuit; finally, perform electroless nickel plating / immersion gold 10μm to obtain a high thermal conductivity aluminum nitride insulating metal substrate.

Embodiment 3

[0033] A 500? metal tungsten buffer layer is ion-plated on both surfaces of a 0.2mm thick aluminum nitride ceramic plate, and then a 300? mm, the other side of the metal gold surface is electroplated copper 30μm, the conductive layer is thickened, and the measured thermal conductivity is 167W / m·K. Then stick a film on the surface of the metal copper plating, etch to obtain the required circuit; finally, electroplate tin to 20 μm to obtain an aluminum nitride insulating metal substrate with high thermal conductivity.

[0034] The high thermal conductivity aluminum nitride insulating metal substrates prepared in the three examples were baked at 300°C for 10 minutes, and there was no peeling phenomenon between the multilayer metal layers, and the performance reliability was extremely high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com