Rare earth permanent magnet material and preparation method thereof

A rare earth permanent magnet, permanent magnet technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of the decline of the magnetic properties of permanent magnets, the rapid emergence of unfavorable products, and the high price of dysprosium elements, so as to improve performance and promote industrial process, the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

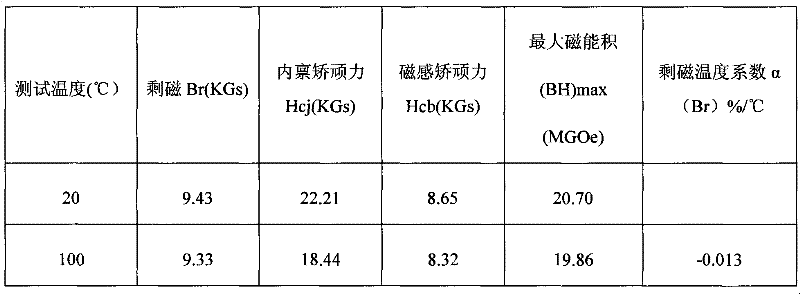

Embodiment 1

[0027] (1) Weigh raw materials: samarium, cobalt, iron, copper, zirconium, dysprosium, gadolinium, erbium; ratio of various raw materials: samarium 16.9%, cobalt 49%, iron 15.5%, copper 6.3%, zirconium 2.6%, dysprosium 1.6%, gadolinium 5.8%, erbium 2.3%.

[0028] (2) Manufacture of quick-setting cast pieces: prepare alloy cast pieces by quick-setting thin slice technology (quick-setting thin slice technology is a mature technology applied to the NdFeB industry, which belongs to the conventional technology in the field, and will not be described here) to obtain fine grains , Alloy casting sheet with uniform composition;

[0029] (3) Pulverizing: carry out hydrogen crushing and rod milling to the alloy cast sheet obtained in step (2), obtain the magnetic powder of average particle size 3.0~5 microns; ) into the reaction vessel of hydrogen to make the hydrogen pressure reach 1MPa, raise the temperature to 150°C and keep it warm for 20h, so that the hydrogen absorption reaction b...

Embodiment 2

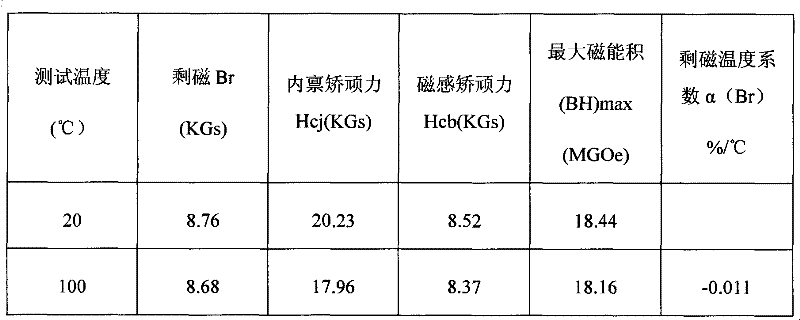

[0036] Raw materials: samarium, cobalt, iron, copper, zirconium, dysprosium, gadolinium, erbium

[0037] The ratio of various raw materials: Samarium 16.8%, Cobalt 50%, Iron 16%, Copper 5.8%, Zirconium 2.9%, Dysprosium 2.0%, Gadolinium 4.1%, Erbium 2.4%.

[0038] The preparation method is the same as in Example 1.

[0039] The test performance of the samarium-cobalt permanent magnet sample prepared in this embodiment is shown in Table 2 below:

[0040] The test performance of table 2 embodiment 2 samarium cobalt permanent magnet sample

[0041]

Embodiment 3

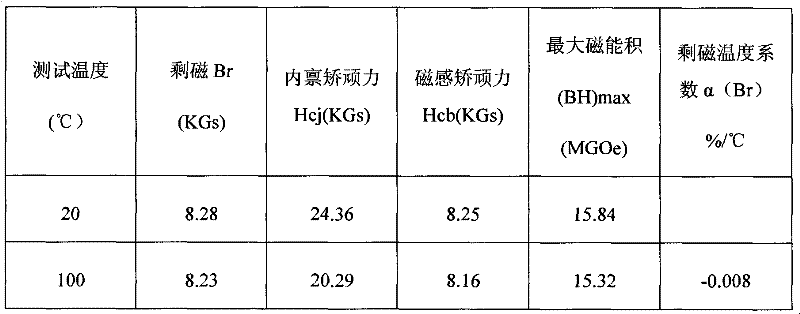

[0043] Raw materials: samarium, cobalt, iron, copper, zirconium, dysprosium, gadolinium, erbium

[0044] The ratio of various raw materials: samarium 19.1%, cobalt 48.2%, iron 14.2%, copper 4.9%, zirconium 3%, dysprosium 2.5%, gadolinium 3.5%, erbium 4.6%.

[0045] The preparation method is the same as in Example 1.

[0046] The test performance of the samarium cobalt permanent magnet sample prepared in this embodiment is shown in the following table 3:

[0047] The test performance of table 3 embodiment 3 samarium cobalt permanent magnet samples

[0048]

[0049] It can be seen from the samples prepared in the above examples that the samarium cobalt permanent magnet of the present invention still has the advantages of high magnetic energy product and low temperature coefficient of remanence under the premise of reducing cost.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com