Reinforced thermoplastic composite wall pipe, strip and its complete production equipment

A technology of composite structure and production device, applied in the direction of pipe/pipe joint/pipe fitting, pipe, rigid pipe, etc., can solve the problem that users are difficult to accept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

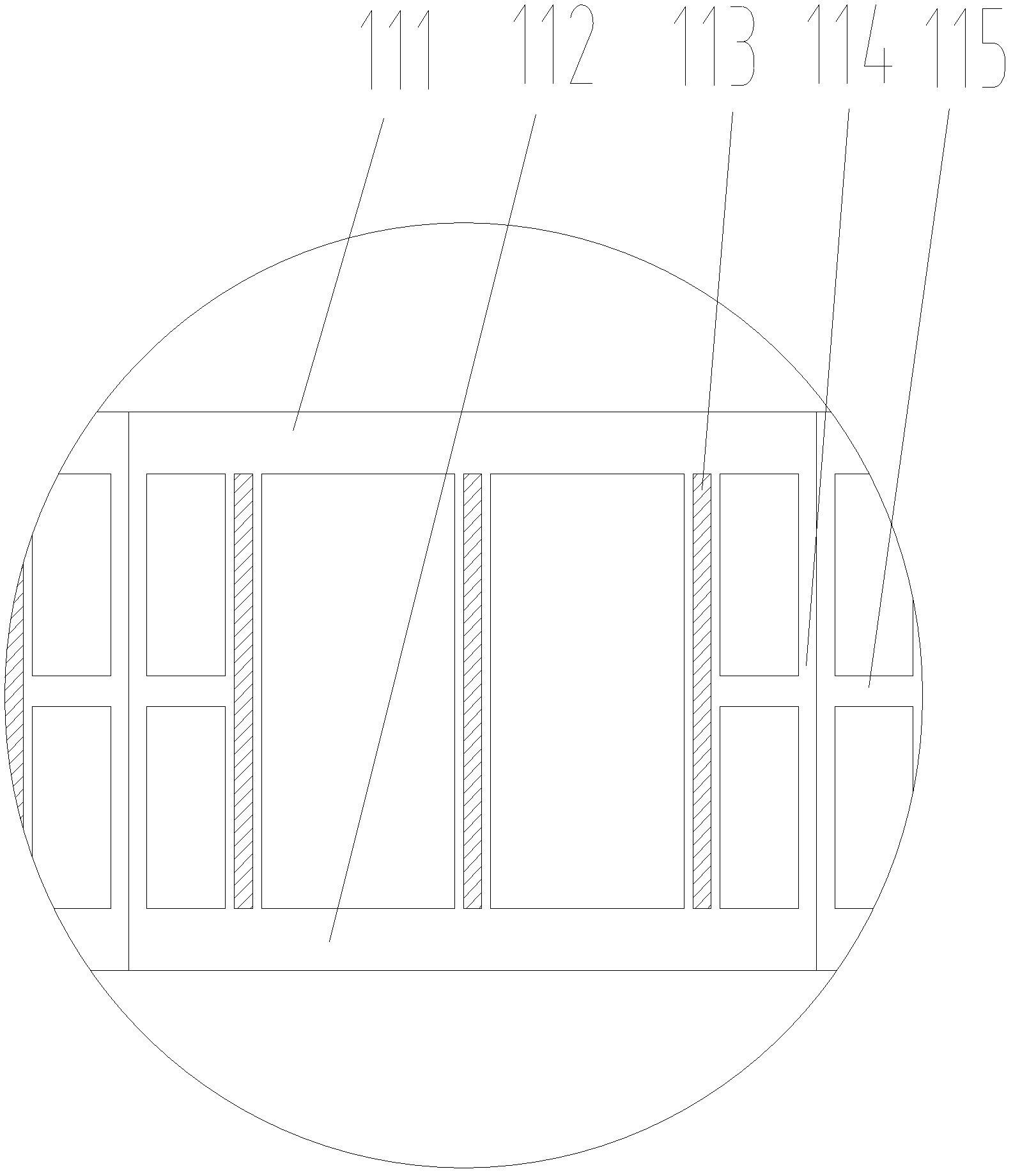

[0091] The first core of the present invention is to disclose a reinforced thermoplastic composite structural wall pipe strip, which can be wound into a reinforced thermoplastic composite structural wall pipe pipe.

[0092] The second core of the present invention is to disclose a reinforced thermoplastic composite structure wall pipe, which is characterized in that the consumption of raw materials can be significantly reduced while improving the ring stiffness of the pipe.

[0093] The third core of the present invention is to disclose a complete set of production equipment for reinforced thermoplastic composite structure wall pipes, which can simultaneously realize the continuous production of reinforced thermoplastic composite structure wall pipe strips and reinforced thermoplastic composite structure wall pipe pipes, and improve production efficiency .

[0094]The following will clearly and completely describe the technical solutions in the embodiments of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com