Method for preparing nanostructured lipid carrier (nlc) and product

A nanostructured lipid and carrier technology, applied in liposome delivery, nanotechnology, nanotechnology, etc., can solve the problems of high heating stability and heating process reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention relates to a preparation method of nanostructure lipid carrier (nanostructure lipid carrier, NLC) or nanoemulsion (nano-emulsion), comprising combining an oil phase containing solid lipid, liquid lipid or a combination thereof with lipophilic surface active The liquefaction is carried out at a temperature higher than the melting point of the oil phase to avoid recrystallization of the oil phase; the active ingredient is added to the liquefied oil phase, after which the oil phase is mixed into a In the water phase to form a mixture, wherein, when the oil phase is mixed with the water phase, the water phase is preheated to a temperature that can avoid recrystallization of the oil phase; a pre-emulsion (pre-emulsion) is formed from the mixture; Preemulsion homogenization is used to provide the nanostructured lipid vehicle; characterized by cooling the formed preemulsion and / or nanostructured lipid vehicle.

[0026] In addition, the present invention f...

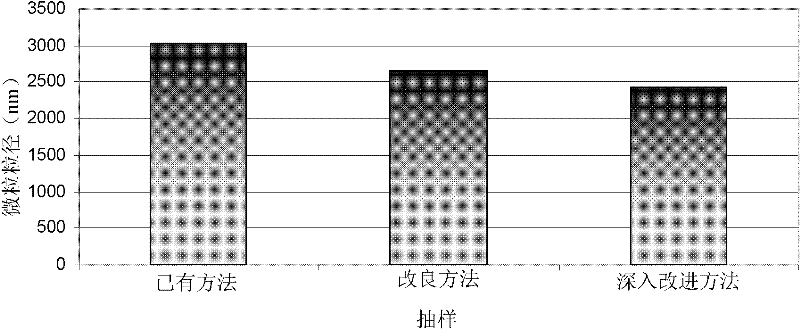

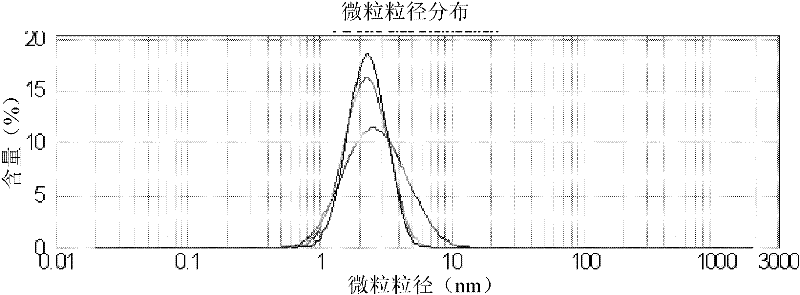

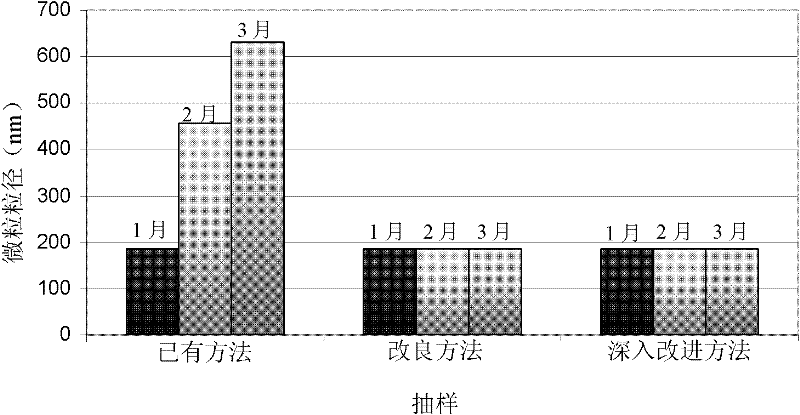

Embodiment 1

[0040] The present invention has successfully developed and established an improved production method. Specifically, a low-temperature production technique was developed to minimize activity loss. This improved method reduces the heating temperature of the oil phase and water compared with the existing established method. The purpose of the surfactant in the water phase is to facilitate its heating to 10° C. above the heating temperature of the oil phase, so as to avoid recrystallization of the oil phase. Likewise, the heating temperature for the second homogenization (high pressure homogenization) was also lowered. In addition, the newly added steps also minimize the loss of active ingredients during the production process. The newly added steps include the following: adding the active substance after reaching the expected temperature, and adopting a rapid cooling step after high shear and high pressure homogenization, respectively. After homogenization, the kinetic energy...

Embodiment 2

[0047] Although the modified method has been proven to be effective in minimizing the degradation of the active ingredient, the method can still be further improved, because the temperature increase of the pre-emulsion during the homogenization process will also lead to the degradation of the active ingredient. Therefore, the improved method requires a profound improvement, namely lowering the temperature of the homogenization process. This second change method is the in-depth improvement method mentioned above when referring to the improvement method. The products of the improved method and the further improved method are the same. The only difference is the pre-preparation of the pre-emulsion. For the modified method, hydrophilic surfactants are added to the water phase and lipophilic surfactants are added to the oil phase. However, evaporation of the aqueous phase in the modified process causes loss of the hydrophilic surfactant. Therefore, in a further improvement metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com