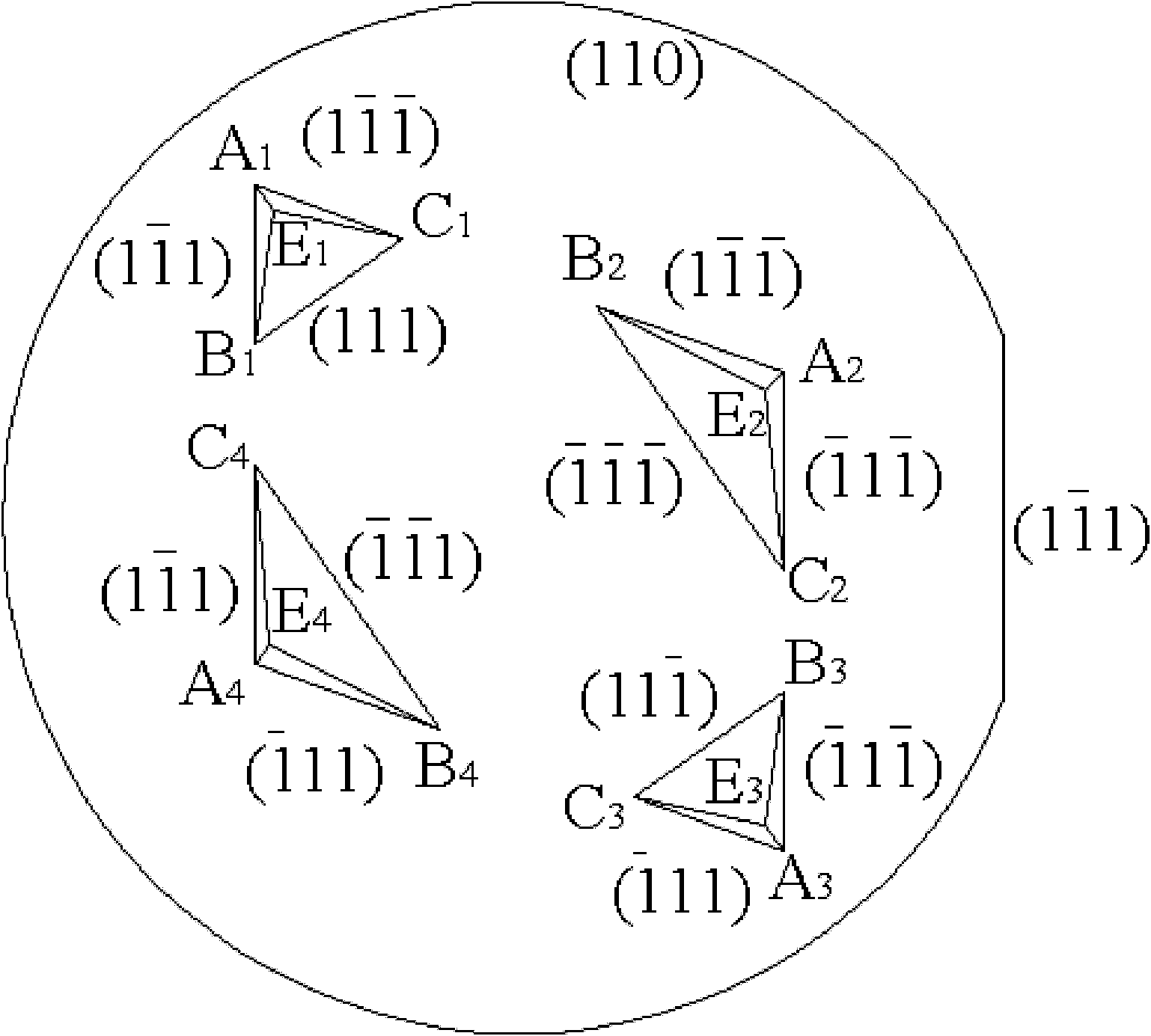

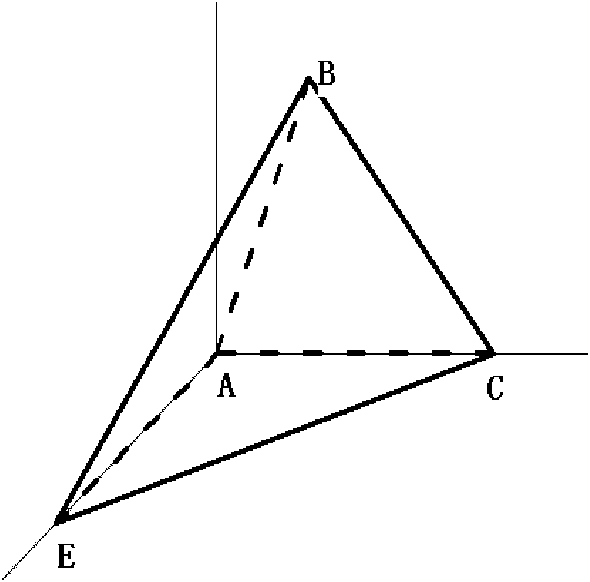

A Fabrication Method of Microcantilever Probe Based on (110) Single Crystal Silicon

A technology of micro-cantilever beam and manufacturing method, which is applied in the field of MEMS and testing, can solve the problem that the taper of the needle tip is not easy to control, and achieve the effect of low cost and good optical surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] For the silicon nitride micro-cantilever probe manufactured in this embodiment, the length of the micro-cantilever is 450 microns, the width is 70 microns, and the tip height is 5 microns. A micro-cantilever beam probe was fabricated using an N-type (110) double-sided polished single-crystal silicon wafer with a thickness of 310 microns as the substrate.

[0048] Its specific production process is as follows:

[0049] ①Conventional thermal oxidation of single crystal silicon wafer 1, forming upper surface silicon dioxide layer 2 and lower surface silicon dioxide layer 3 on the single crystal silicon wafer, the thickness of the oxide layer is about 1 micron, as attached Figure 3a .

[0050] ②Silicon wafer backside treatment process: backside photolithography, and use hydrofluoric acid buffer solution (BHF) to etch silicon dioxide to produce a rectangular window pattern 3′ with silicon dioxide removed, as shown in the attached Figure 4a , so that silicon is exposed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com