Medium microwave dielectric material and its preparation method and application

A microwave dielectric material and intermediary technology, applied in inorganic insulators, ceramics, etc., can solve the problems of deterioration of resonant frequency temperature coefficient, little research on low-temperature sintering, and difficulty in meeting practical applications, to improve the resonant frequency temperature coefficient and simple process. , the effect of short sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

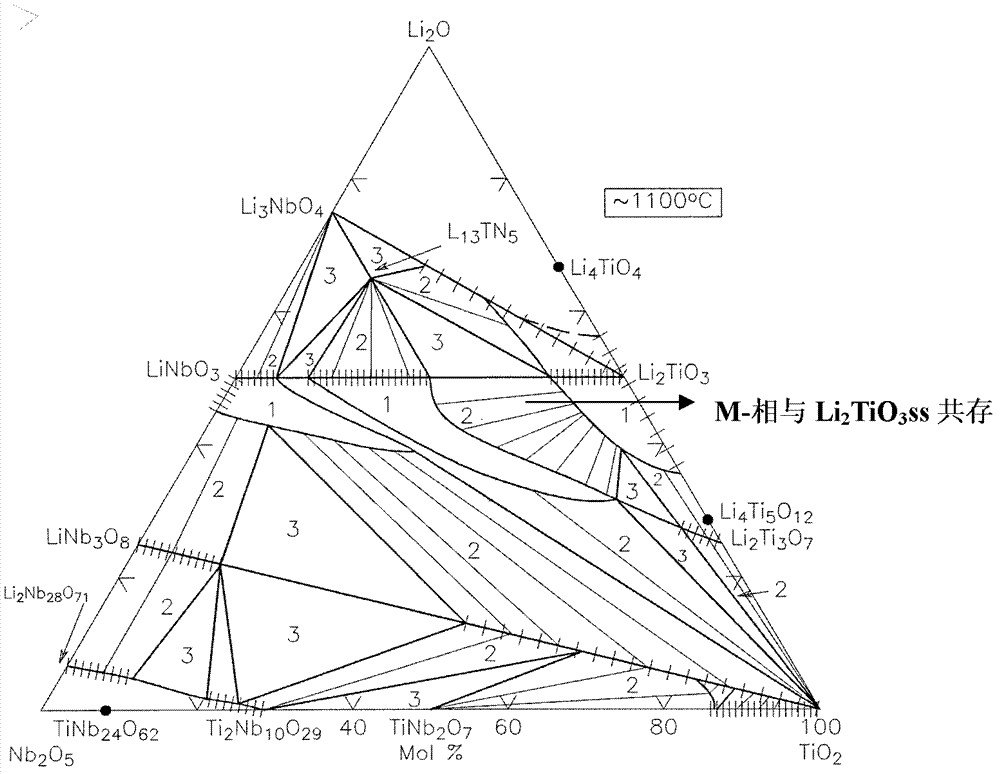

[0036] The raw material formula of the present embodiment is: 100 parts by weight Li 2 O-Nb 2 o 5 -TiO 2 System (Li 2 CO 3 , Nb 2 o 5 and TiO 2 The molar ratio is 1:0.2:1), add 2 parts by weight of ZnO, and add 1 part by weight of B 2 o 3 as a sintering aid.

[0037] The preparation steps are:

[0038] (1) Will Li 2 CO 3 , Nb 2 o 5 and TiO 2 Weigh at a molar ratio of 1:0.2:1, and weigh 2 parts by weight of ZnO, add ethanol according to the weight ratio of the mixture to ethanol at 1:1.0, mix in a rolling mill with a rotation speed of 200r / min for 36h, and bake at 60°C. Dry, then grind the dry powder with an agate mortar, put it into a high-alumina crucible, and pre-fire it at 800°C for 8h.

[0039] (2) Add 1 weight part of B to the powder after pre-burning 2 o 3 , be 1: 1.2 by the weight ratio of compound material and ethanol, add ethanol, be that 200r / min rolling mill mixes 36h at rotating speed, 60 ℃ dry stand-by, add 5wt% polyvinyl alcohol PVA aqueous solu...

Embodiment 2

[0045] The raw material formula of the present embodiment is: 100 parts by weight Li 2 O-Nb 2 o 5 -TiO 2 System (Li 2 CO 3 , Nb 2 o 5 and TiO 2 The molar ratio is 1:0.2:1), add 4 parts by weight of ZnO, and add 1 part by weight of B 2 o 3 as a sintering aid.

[0046] The preparation steps are:

[0047] (1) Will Li 2 CO 3 , Nb 2 o 5 and TiO 2 Weigh at a molar ratio of 1:0.2:1, and weigh 4 parts by weight of ZnO, add ethanol according to the weight ratio of the mixture to ethanol of 1:1.0, mix at a rolling mill at a speed of 400r / min for 18h, and dry at 100°C. Then the dry powder was ground with an agate mortar, put into a high-alumina crucible, and pre-fired at 900°C for 2 hours.

[0048] (2) Add 1 weight part of B to the powder after pre-burning 2 o 3 , be 1: 1.2 by the weight ratio of compound material and ethanol, add ethanol, be that 400r / min rolling mill mixes 18h at rotating speed, 100 ℃ dry stand-by, add 5wt% polyvinyl alcohol PVA alcohol solution ( Th...

Embodiment 3

[0053] The raw material formula of the present embodiment is: 100 parts by weight Li 2 O-Nb 2 o 5 -TiO 2 System (Li 2 CO 3 , Nb 2 o 5 and TiO 2 The molar ratio is 1:0.2:1), add 6 parts by weight of ZnO, and add 0.5 parts by weight of B 2 o 3 as a sintering aid.

[0054] The preparation steps are:

[0055] (1) Will Li 2 CO 3 , Nb 2 o 5 and TiO 2 Weigh at a molar ratio of 1:0.2:1, and weigh 6 parts by weight of ZnO, add ethanol according to the weight ratio of the mixture to ethanol of 1:0.6, mix in a rolling mill at a speed of 300r / min for 24h, and dry at 70°C. Then the dry powder was ground with an agate mortar, put into a high alumina crucible, and pre-fired at 850°C for 5h.

[0056] (2) Add 0.5 parts by weight of B to the powder after pre-burning 2 o 3 , be 1: 2 by the weight ratio of compound material and ethanol, add ethanol, be that 300r / min rolling mill mixes 24h at rotating speed, 70 ℃ dry stand-by, add 5wt% polyvinyl alcohol PVA aqueous solution (mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com