Light-diffusing dimethyl organic silicone rubber composition and LED light-diffusing molding body

A technology of silicone rubber and dimethyl polysiloxane, which is applied in the field of LED light-diffusing moldings and light-diffusing dimethyl silicone rubber compositions, and can solve the problem of deterioration, lack of light scattering, light Unstable scattering and other problems, to achieve the effect of wide temperature range and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

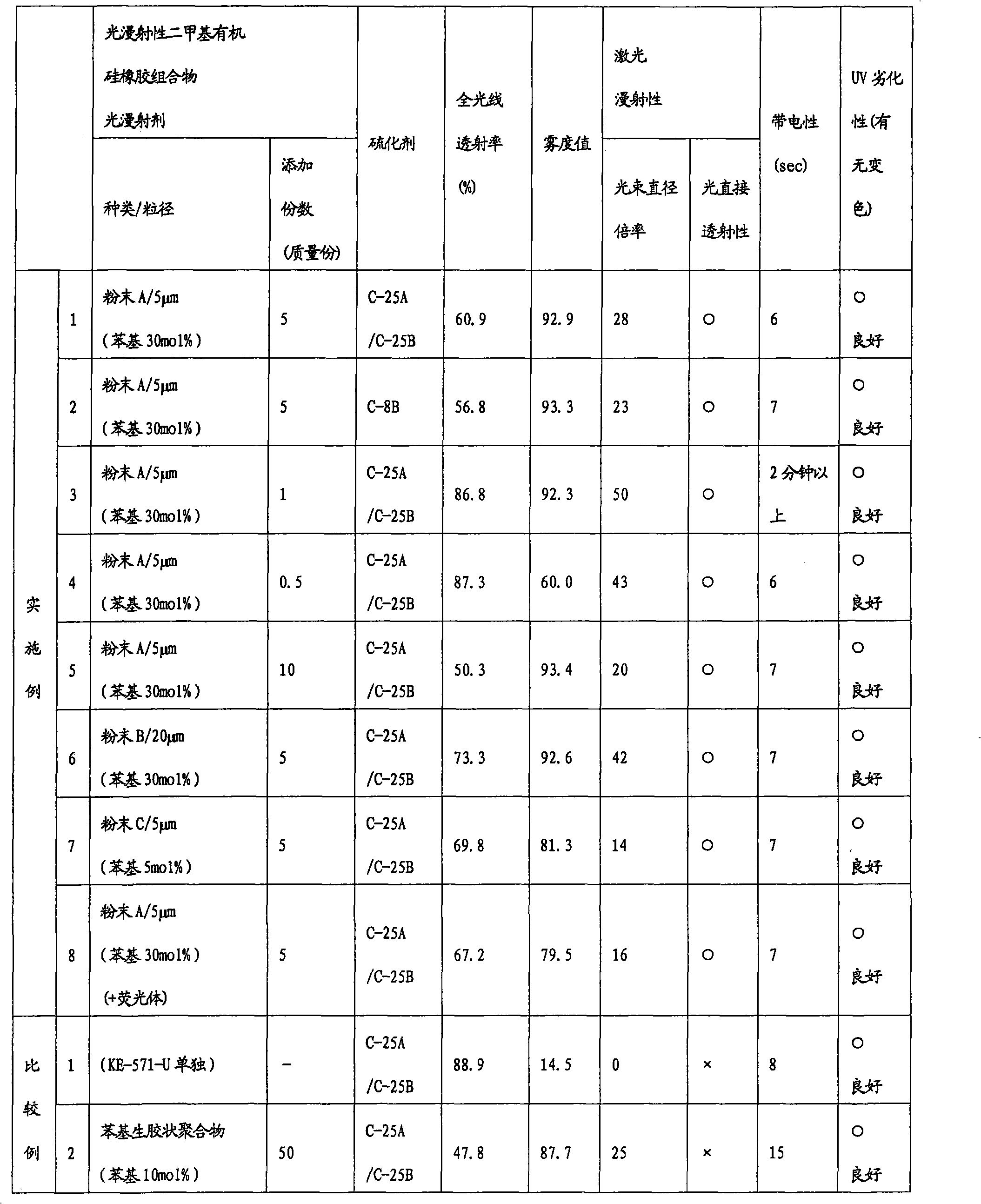

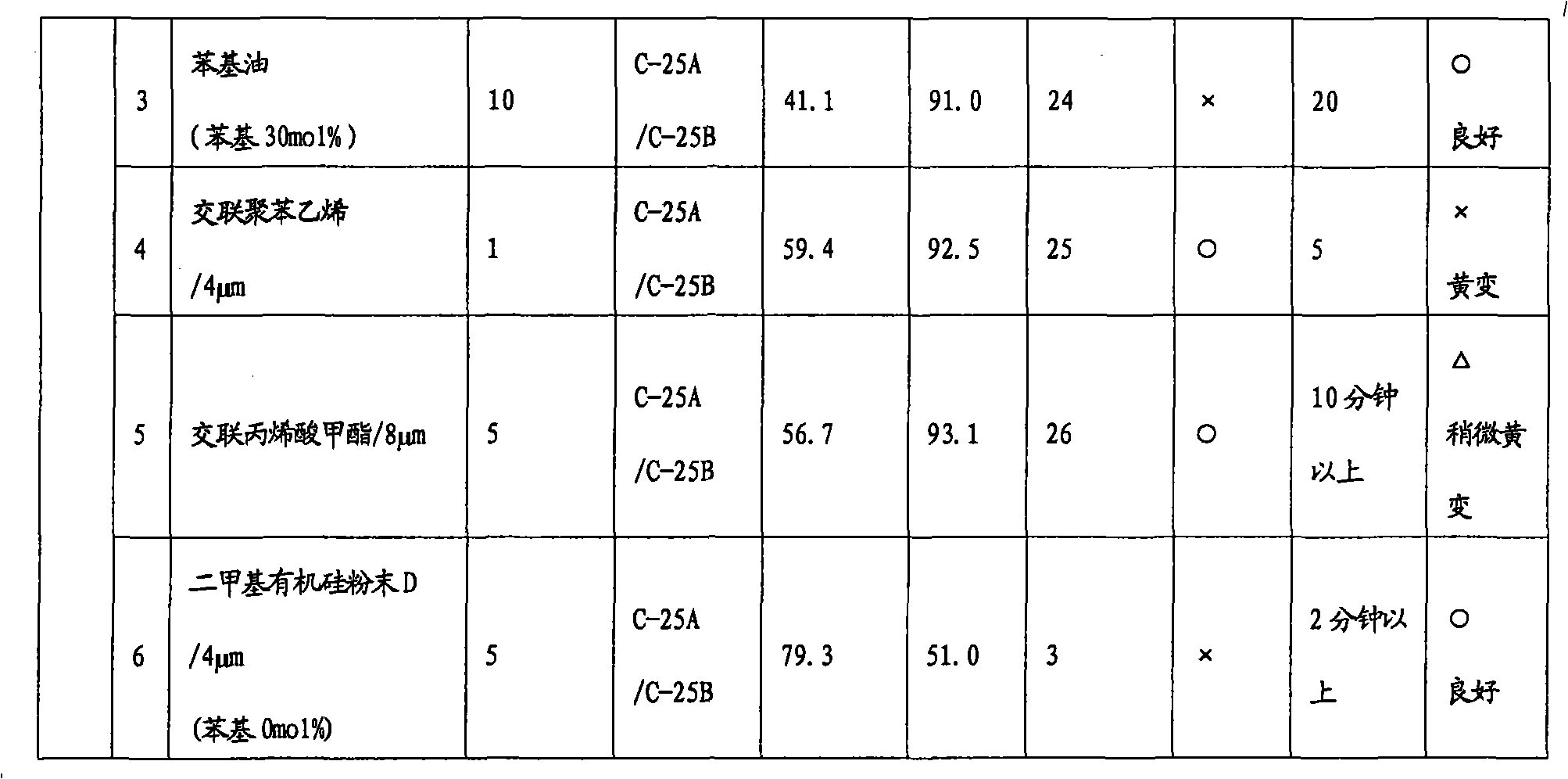

Examples

Embodiment 1

[0082] In the kneadable dimethyl silicone rubber compound KE-571-U (manufactured by Shin-Etsu Chemical Co., Ltd., which is a transparent uncrosslinked dimethyl silicone rubber compound, the dimethyl silicone rubber compound with a degree of polymerization of about 5000 The specific surface area measured by the BET method is 200m 2 / g of dry silica and 10% by mass or less of dimethylorganosiloxane oligomers (silica dispersant) with a molecular weight of less than 700 and terminated by silanol groups at both ends, and the compound does not contain In 100 parts by mass of phenyl groups), add spherical phenylmethyl silicone rubber powder (powder powder) as a light diffusing agent with an average particle diameter of 5 μm, a phenyl group content of 30 mol%, a refractive index of 1.52, and a durometer A-type hardness of 30. A) 5.0 parts by mass and 500 ppm of LiN(SO 2 CF 3 ) 2 , and kneading and dispersing with a kneader to obtain a milky white light-diffusing dimethyl silicone r...

Embodiment 2

[0096] To 100 parts by mass of the light-diffusing dimethyl silicone rubber composition matrix of Example 1, 1.0 parts by mass of an organic peroxide-based vulcanizing agent C-8B (manufactured by Shin-Etsu Chemical Co., Ltd.) was added as a crosslinking agent , kneaded with two rolls, and press-molded in the same manner as in Example 1, and performed various measurements in the same manner as in Example 1 with the obtained cured sheet with a thickness of 2 mm.

Embodiment 3

[0098] In Example 1, the light diffusing agent (powder A) was reduced to 1 part by mass, and LiN(SO 2 CF 3 ) 2 , except that addition crosslinking was performed in the same manner as in Example 1 to produce a 2 mm sheet, and various measurements were performed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com