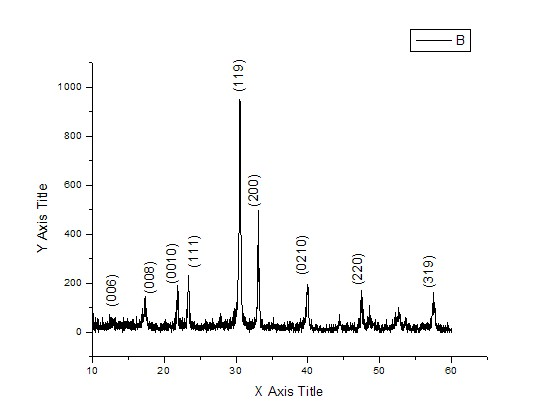

Method for preparing thick film from polycrystalline ca0.4sr0.6bi4ti4o15 nano-powder with perovskite structure

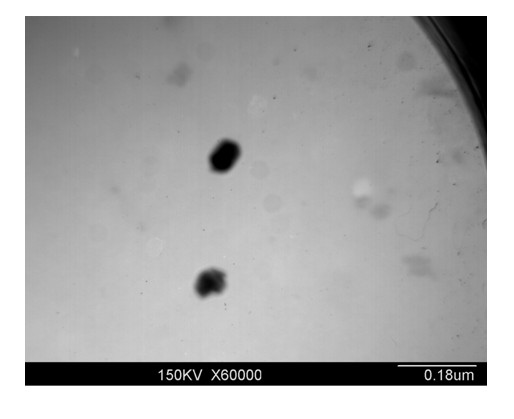

A ca0.4sr0.6bi4ti4o15, perovskite structure technology, applied in the field of ceramic material preparation, can solve the problem of difficulty in accurately controlling the particle size and particle size distribution of nano-powders, expensive equipment, and difficulty in obtaining uniform and stable powder sol suspension. Liquid and other problems, to achieve the effect of narrow size distribution, good dispersion and fine particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Polycrystalline Ca with perovskite structure 0.4 Sr 0.6 Bi 4 Ti 4 o 15 The method for preparing a thick film from a nanopowder, the specific steps are as follows:

[0033] (1) Prepare solution A with tetrabutyl titanate and acetylacetone at a ratio of 1:1 by volume: take 50ml of tetrabutyl titanate, use 50ml of acetylacetone as a chelating agent, and use a pipette to slowly dissolve 50ml of acetylacetone Slowly drop into the tetrabutyl titanate solution, and at the same time, in order to keep the temperature of the solution constant, put the beaker containing the solution in ice water at 0°C after mixing, and keep stirring the mixed solution to prevent the heat generated during the chelation process Hydrate the mixed solution; fully stir the mixed solution on a magnetic stirrer for 12 hours to obtain a clear yellow-brown transparent A solution;

[0034] (2) Weigh 77g of bismuth nitrate, 5g of strontium acetate, and 3.5g of calcium nitrate into 100ml of solvent ethy...

Embodiment 2

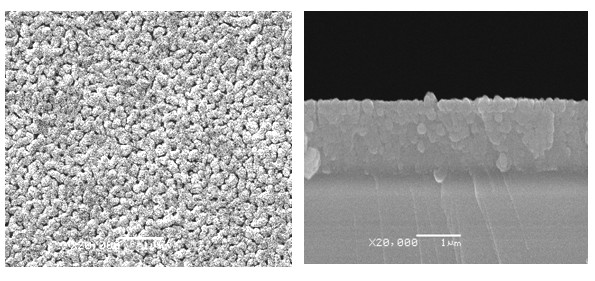

[0041]The mixing temperature in step (3) is 35°C; the drying time in step (4) is 8 days; other conditions are the same as in Example 1. The thick film prepared with the powder of Example 4 has a smooth surface without cracks, clear particles, large size, and a thickness of about 1.5 μm, meeting the application requirements of micro-electro-mechanical systems (MEMS).

Embodiment 3

[0043] The mixing temperature in step (3) is 25°C; the drying time in step (4) is 12 days; other conditions are the same as in Example 1. The surface of the thick film prepared by the powder of Example 3 is smooth without cracks, the particles are clear, the size is large, and the thickness reaches about 1.5 μm, which meets the application requirements of micro-electro-mechanical systems (MEMS).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com