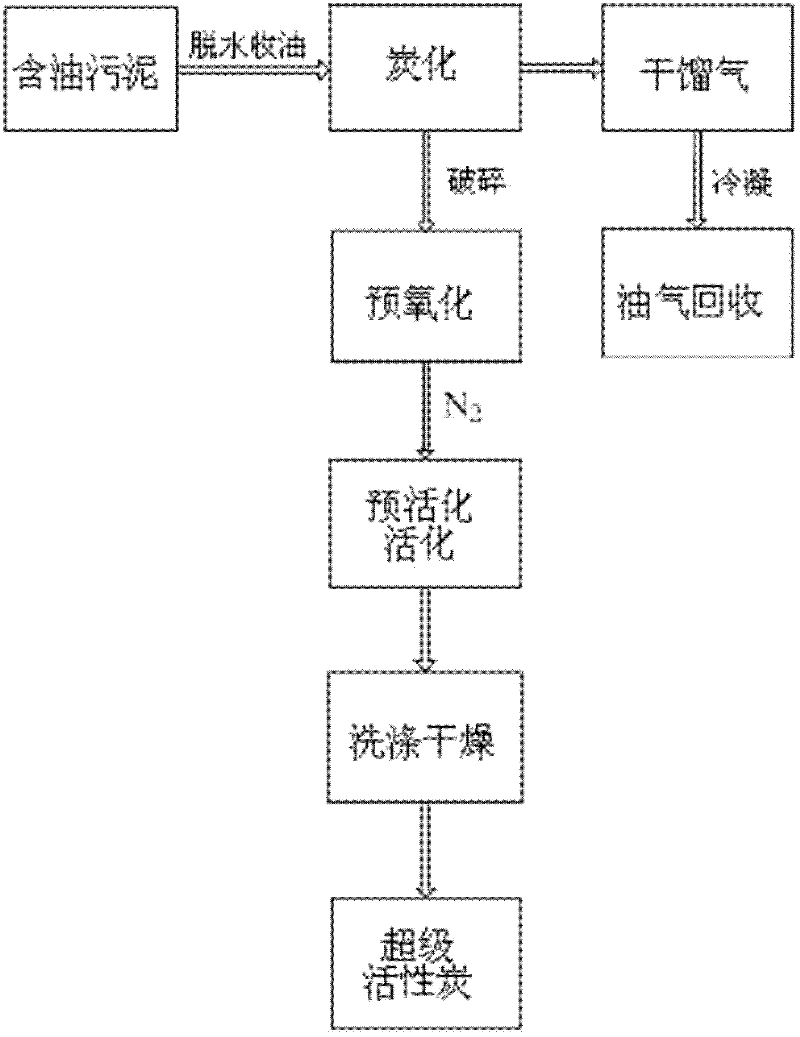

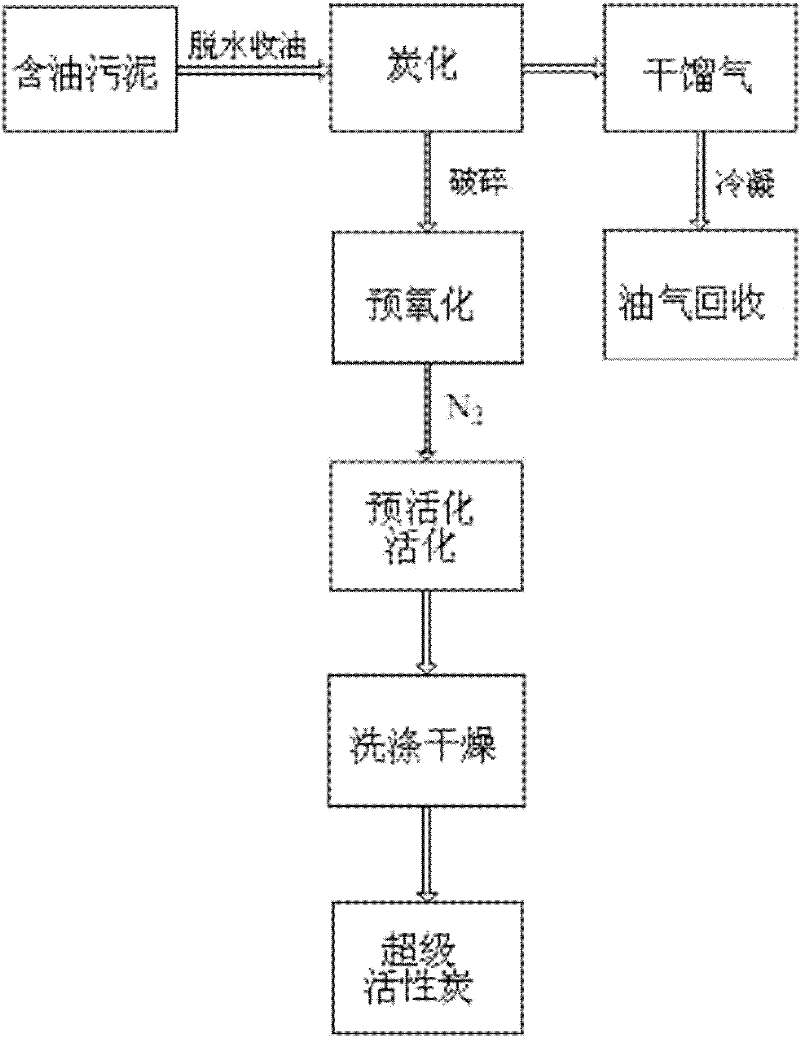

A method for preparing super activated carbon from oily sludge

A technology for activated carbon and sludge, which is applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as inability to achieve, achieve economical feasibility and economy, and the preparation process is simple to operate and simple to prepare. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Prepare conditioning treatment agent: calcium chloride and OP-10 surfactant are mixed by mass ratio 30: 0.6, then add water and be mixed with aqueous solution, the concentration of calcium chloride and OP-10 surfactant mixture aqueous solution is 35%; Namely The mass ratio of the mixture of calcium chloride and OP-10 surfactant to water is 35:65.

[0031] Prepare composite activator: composite activator is potassium hydroxide (KOH) and potassium carbonate (K 2 CO 3 ) mixture with a mass ratio of 10:2.

[0032] Sewage treatment station sludge with a water content of 86.8%. According to the mass ratio of sludge to medicine 10:3, add conditioning treatment agent for dehydration treatment, send the dehydrated sludge with a moisture content of 68% into the carbonization furnace, and heat up to 450°C at a speed of 12°C / min under the isolation of air for carbonization. The carbonization time is 2 hours; the dry distillation gas generated during carbonization is collected an...

Embodiment 2

[0035] Prepare composite activator: composite activator is solid sodium hydroxide (NaOH) and sodium carbonate (NaOH) 2 CO 3 ) mixture with a mass ratio of 10:1.

[0036] Send the oilfield tank bottom mud with a moisture content of 63.7% into the carbonization furnace, and heat it up to 500°C at a rate of 8°C / min in the absence of air for carbonization. The carbonization time is 4 hours. After the carbonization is completed, the furnace temperature drops to room temperature. Take out the carbonization; The carbonization is broken to 200 orders, and the carbonization after the crushing is immersed in the prepared 20% hydrogen peroxide (H 2 o 2 ) solution, carry out pre-oxidation treatment, stir continuously at room temperature for 4 hours to make it evenly mixed, wash with water until neutral after the reaction stops, and dry for 6 hours at 110°C; 2 mass ratio mixed evenly, in N 2 Under the atmosphere, the temperature was raised to 200°C at a speed of 15°C / min for pre-activati...

Embodiment 3

[0039] Prepare conditioning treatment agent: mix solid sodium chloride and OP-10 surfactant at a mass ratio of 30:0.4, then add water to prepare an aqueous solution with a mass percent concentration of 48%.

[0040] Prepare composite activator: composite activator is potassium hydroxide (KOH) and potassium carbonate (K 2 CO 3 ) mixture with a mass ratio of 10:5.

[0041] The oilfield sewage treatment station sludge with a water content of 90.5% is dehydrated by adding a conditioning treatment agent at a mass ratio of 10:1 to the sludge, and the dehydrated sludge with a water content of 66% is sent to the carbonization furnace. The speed of ℃ / min is raised to 450 ℃ for carbonization, and the carbonization time is 2 hours; after the carbonization is completed, after the furnace temperature drops to room temperature, take out the carbonized product, crush the carbonized product to 230 mesh, and crush the crushed carbonized product according to the mass ratio of 1:4 Immerse in p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com