Method for processing whole sintering type super-hard abrasive honing tool case

A technology of superhard abrasives and processing methods, which is applied in honing tools, metal processing equipment, manufacturing tools, etc. It can solve the problems of affecting the service life of the tool holder, the diamond grinding disc is easy to fall off, and the change of the tool body is inconsistent, so as to improve the service life. , The internal structure is uniform and dense, and the effect of reducing the cutting load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

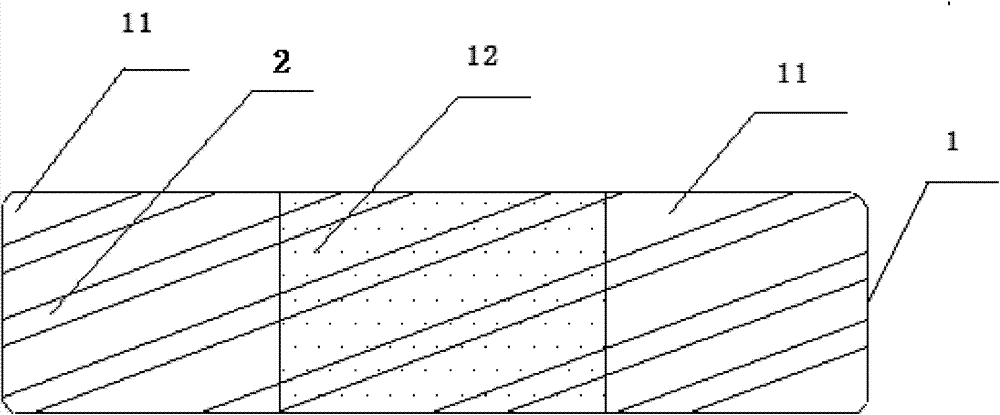

[0029] Evenly distribute the copper powder in the mold, and evenly mix the powdered diamond and metal binder into the middle part of the cutter body, stir evenly, so that the diamond is evenly mixed into the binder, and press through the mold to form a hollow cylindrical molded part 1; In terms of weight percentage, the total amount of copper powder and metal binder is 40%; diamond is 60%; in terms of weight, the ratio of copper powder and metal binder is 3:1; The guide part 11 is processed by copper powder, and the middle part 12 of the molded part 1, that is, the cutting part of the cutter sleeve, is processed by a mixture of copper powder and diamond. The molded part 1 is sintered at a temperature of 700° and the sintering time is 2 hours, keep warm for 2 hours, and then cool naturally in the air; the sintered molded part 1 is grooved by a special electric spark machine to form a chip removal groove 2. The chip flute 2 can be a straight groove or a spiral groove. In order t...

Embodiment 2

[0032] Evenly distribute the copper powder in the mold, and evenly mix the powdered diamond and metal binder into the middle part of the cutter body, stir evenly, so that the diamond is evenly mixed into the binder, and press through the mold to form a hollow cylindrical molded part 1; In terms of weight percentage, the total amount of copper powder and metal binder is 60%; diamond is 40%; in terms of weight, the ratio of copper powder and metal binder is 3:1; The guide part 11 is processed by copper powder, and the middle part 12 of the molded part 1, namely the cutting part of the cutter sleeve, is processed by a mixture of copper powder and diamond. The molded part 1 is sintered at a temperature of 750°C and the sintering time is 2.5 hours, keep warm for 2 hours, and then cool naturally in the air; the sintered molded part 1 is grooved by a special electric spark machine to form a chip removal groove 2. The flute 2 can be a straight groove or a spiral groove. In order to fa...

Embodiment 3

[0035] Distribute the copper powder evenly in the mold, mix the powdery diamond and metal bond evenly in the middle part of the cutter body, and stir evenly, so that the diamond is evenly mixed into the bond, and press it into a hollow cylinder through combination or high-pressure mold Molded part 1; by weight percentage, the total amount of copper powder and metal binder is 80%; diamond is 20%; by weight, the ratio of copper powder and metal binder is 3:1; two parts of molded part 1 The end, that is, the guide part 11 of the knife sleeve is processed by copper powder, and the middle part 12 of the formed part 1, that is, the cutting part of the knife sleeve, is processed by a mixture of copper powder and diamond. The formed part 1 is sintered at a temperature of 800 ℃, the sintering time is 2 hours, the heat preservation is 2 hours, and then naturally cooled in the air; the sintered molded part 1 is grooved by a special electric spark machine to form a chip removal groove 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com