An intermediate frequency inverter resistance spot welding power supply system

A technology of resistance spot welding and power supply system, applied in the direction of welding power supply, resistance welding equipment, welding equipment, etc., can solve the problems of insufficient stability of power supply, insufficient control response speed and adjustment resolution, and large volume, so as to improve the adjustment resolution efficiency and controllability, increase product technical content, and improve the effect of process adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

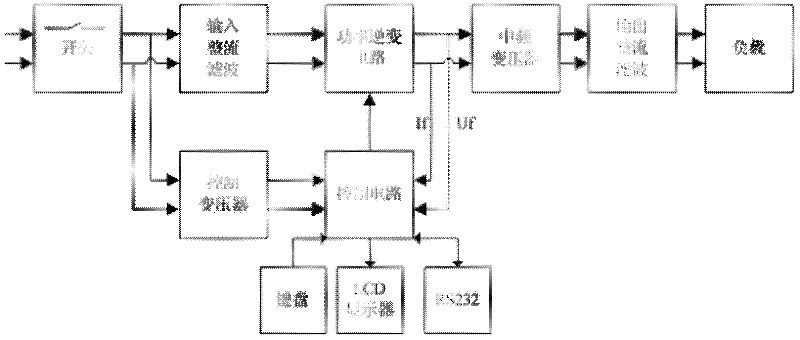

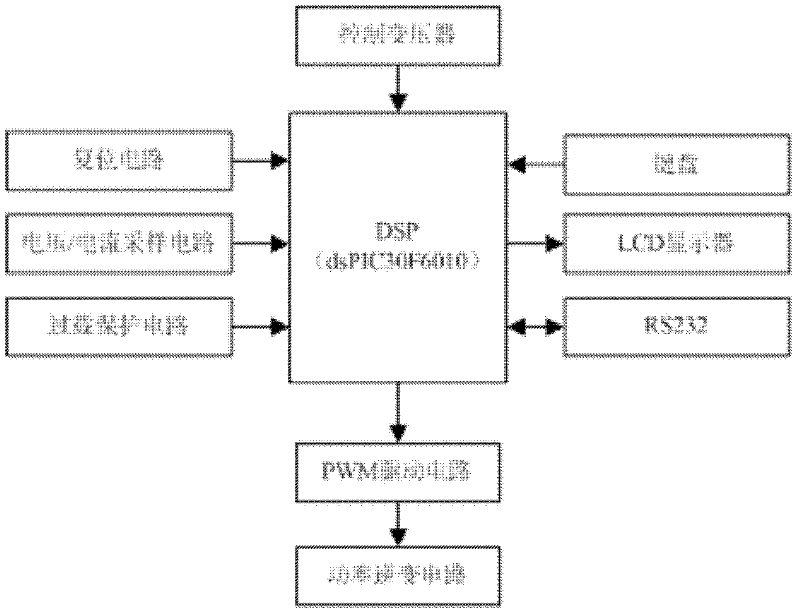

[0038] Such as figure 1 As shown, the intermediate frequency inverter resistance spot welding power supply system of the present invention includes a main circuit and a control system, and the main circuit includes a power switch connected in sequence, an input rectification filter circuit, a power inverter circuit, an intermediate frequency transformer, and an output rectification filter circuit; The control system includes a control transformer and a control circuit; the control transformer and the input rectification filter circuit are respectively connected to the power frequency AC power grid through a power switch, the output rectification filter circuit is connected to the load, and the control circuit is connected to the power inverter circuit, keyboard, display The devices are connected separately, and the control circuit is also connected with the output end of the power inverter circuit.

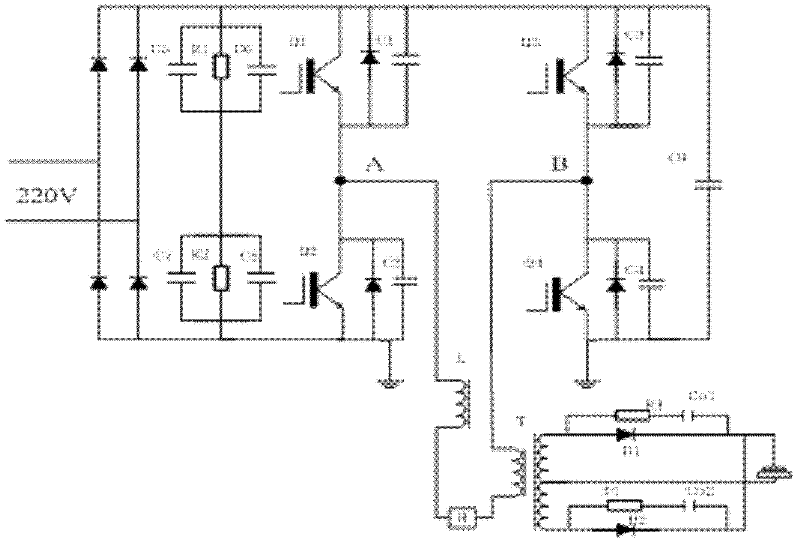

[0039] Such as figure 2 shown. The power inverter circuit is a full-bridge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com