A kind of preparation method of fine spherical tungsten powder

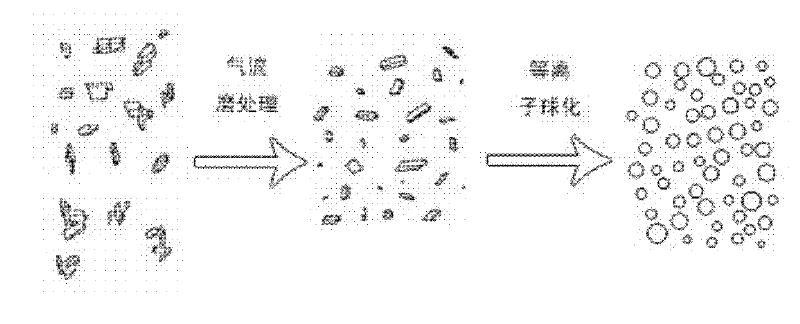

A technology of spheroidizing tungsten powder and ultra-fine tungsten powder, which is applied in the field of powder metallurgy powder preparation, can solve the problems of particle growth and difficulty in making spherical tungsten powder, and achieve good dispersion, smooth surface and uniform particle size distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

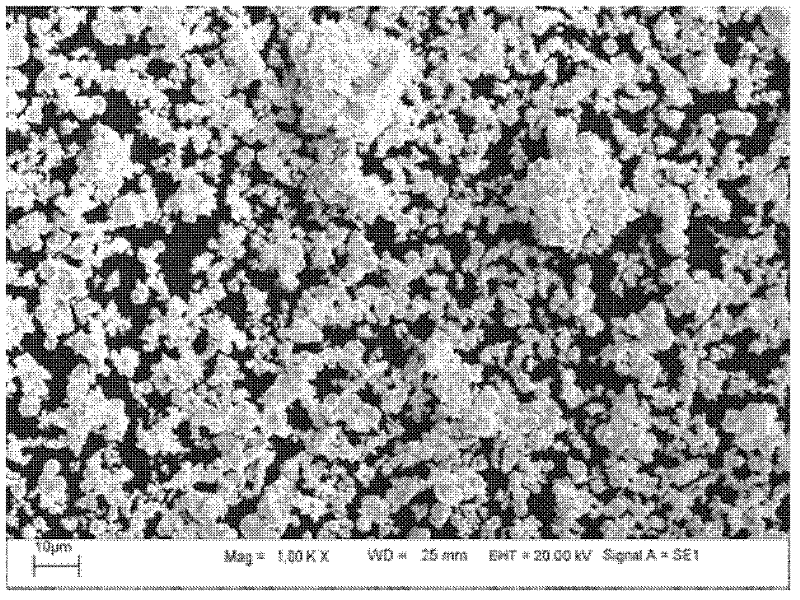

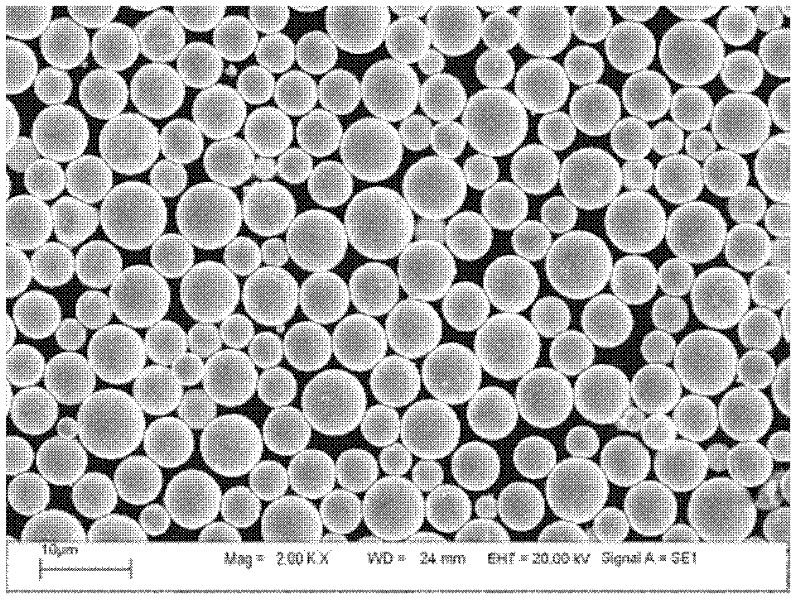

[0022] This embodiment is to prepare spherical tungsten powder with an average particle diameter of 5 μm:

[0023] The average particle size of raw tungsten powder is irregular tungsten powder with an average particle size of 5.184. During the dispersion process, the grinding chamber pressure is 0.7 MPa, the sorting wheel speed is 5000 rpm, and the powder feeding rate is 5 kg / hour; the input power during the spheroidization process is 55KW , The system maintains a 1000mm water column, the powder feeding gas flow is 5 slpm, the working gas flow is 30 slpm, the shielding gas flow is 60 slpm, the powder feeding rate is 20 g / min, the working gas is nitrogen during the dispersion process, and it works during the spheroidization process The gas, powder feeding gas and protective gas are all argon gas.

Embodiment approach 2

[0025] This embodiment is to prepare spherical tungsten powder with an average particle diameter of 3 μm:

[0026] The raw material tungsten powder has an irregular tungsten powder with an average particle size of 2.917, the grinding chamber pressure during the dispersion process is 0.7 MPa, the sorting wheel speed is 5500 rpm, and the powder feeding rate is 5 kg / h; the input power during the spheroidization process is 55 KW , The system maintains a 1000mm water column, the powder feeding gas flow is 5 slpm, the working gas flow is 30 slpm, the shielding gas flow is 70 slpm, the powder feeding rate is 20 g / min, the working gas is nitrogen during the dispersion process, and it works during the spheroidization process The gas, powder feeding gas and protective gas are all argon gas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com