Preparation method of n type GaSb ohmic contact having diffusion impervious layer Mo

A technology of ohmic contact and barrier layer, applied in the direction of laser components, electrical components, lasers, etc., can solve the problems of unfavorable ohmic contact, increased barrier height, low solubility, etc., and achieve the expansion of alloy temperature range and low specific contact resistance , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

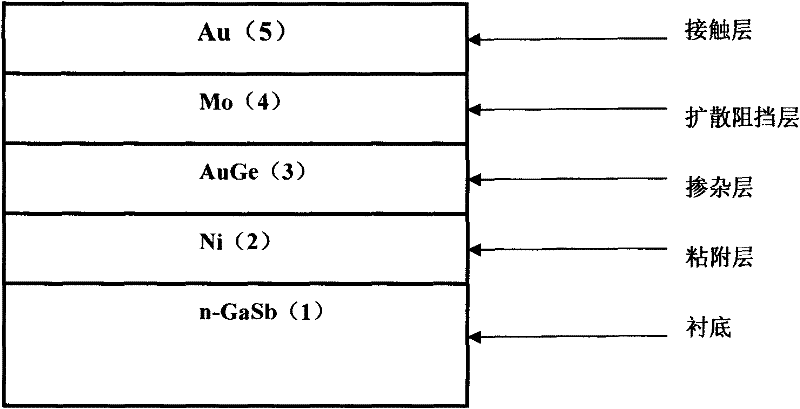

[0009] Such as figure 1 As shown, an n-GaSb-based device ohmic contact structure with a diffusion barrier layer Mo includes n-GaSb substrate (1), Ni adhesion layer (2), Au, Ge doped layer (3), Mo diffusion barrier layer (4), Au contact layer (5). The substrate (1) is a Te-doped GaSb substrate; the thickness of the Ni adhesion layer is 30nm (2); the thickness of the Au and Ge doped layer (Au88%, Ge12%) is 50nm (3); the thickness of the Mo diffusion barrier layer 60nm-100nm (4); Au contact layer 300nm (5);. Illustrate the present invention below in conjunction with example, the equipment that adopts is that the equipment that adopts is DISCOVERY--18 magnetron sputtering furnace. The substrate (1) is (100) orientation doped Te doping concentration is (3~7)×10 17 cm -3 n-GaSb crystal material with a mobility of 3500cm 2 / v·s(T=300K), thickness is 410μm, EPD≤8000 / cm 2 .

[0010] Sputtering the Ni adhesion layer (2), the gas flow rate is 20sccm, the input current is 0.2A; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com