Micromachining method for manufacturing polymer cylindrical microlens by electric field induction

A polymer column and electric field induced technology, applied in the photoengraving process of lens and pattern surface, optics, etc., can solve the problems of difficult processing of cylindrical micro-scale molds, affecting reproduction accuracy, polymer shrinkage, etc., and achieve shortening The effect of processing time, reducing processing cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] A microfabrication method utilizing electric field induction to manufacture polymer cylindrical microlenses, comprising the following steps:

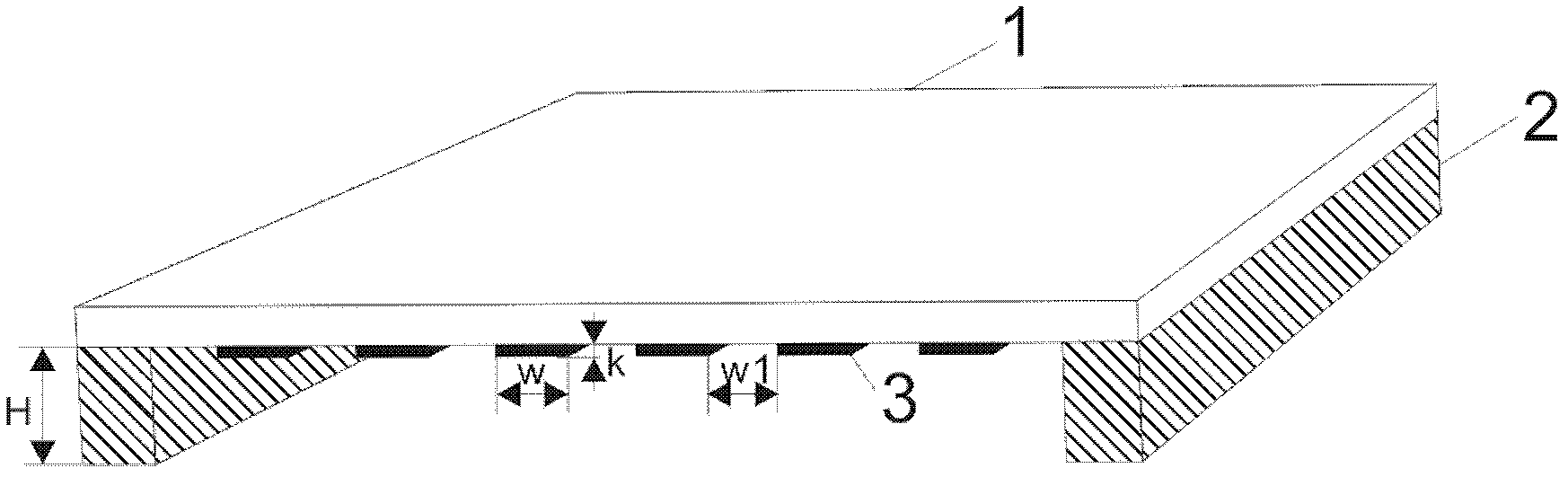

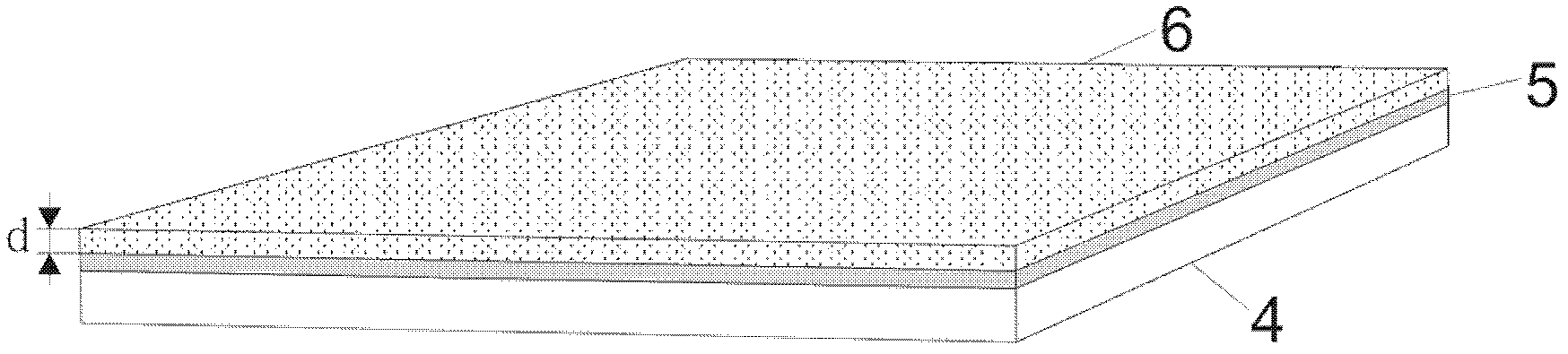

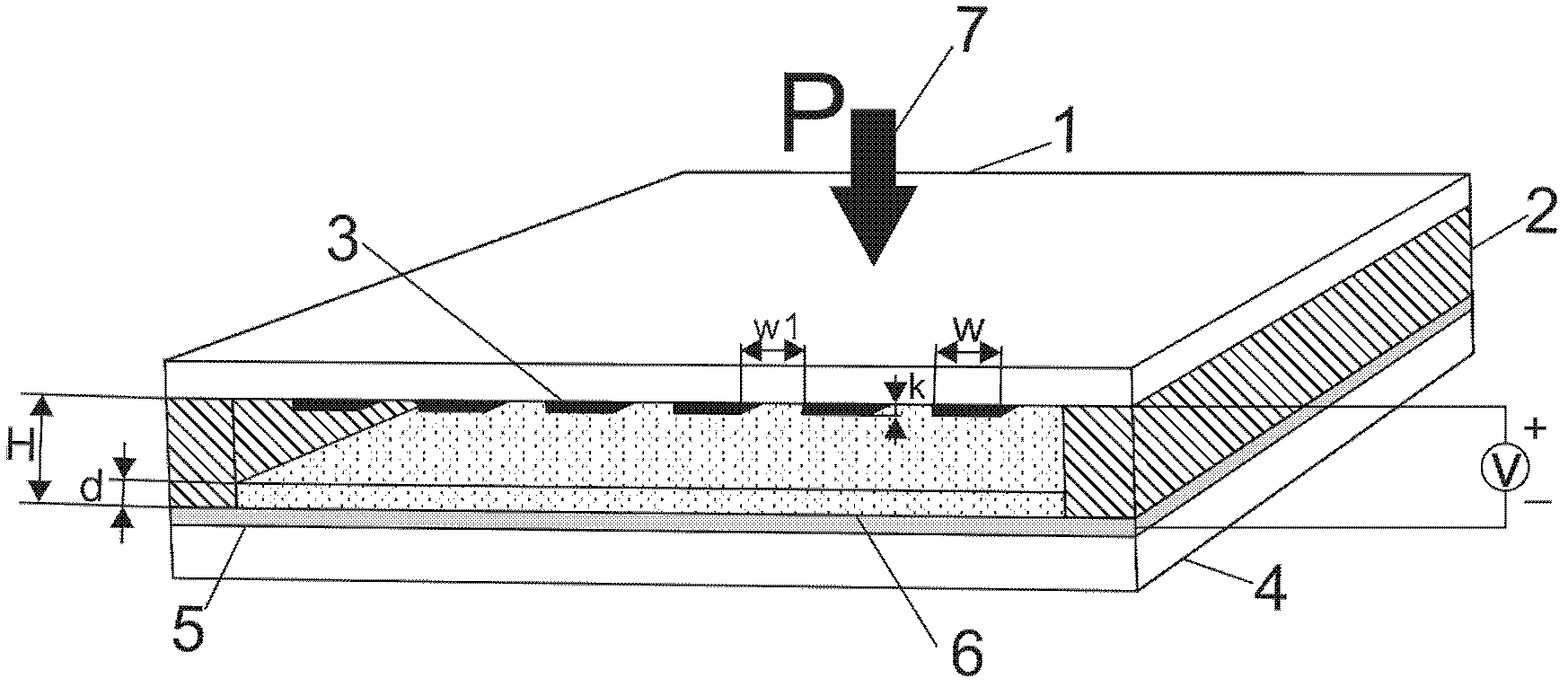

[0025] 1) The negative pattern of the conductive grid line structure is designed as a micron-scale grid line structure. According to the numerical simulation analysis, the conductive grid line structure will generate a cylindrical electric field equivalent surface in space, and the transparent surface is prepared by sputtering deposition and photolithography system. Conductive grid template, as attached figure 1 shown in SiO 2 Substrate 1 uses a photolithography process to process the negative pattern of the conductive grid line structure, and sputters a layer of transparent metal layer with a thickness of nanometers on the patterned photoresist layer with sputtering deposition equipment, and peels off the photoresist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com