Asphalt pavement crack pouring process and pavement crack repair agent

A technology for asphalt pavement and pavement cracks, which is applied in the field of pavement crack repair agents, can solve problems such as increased crack width and depth, unfavorable energy saving, and increased use of materials, so as to improve high temperature stability, avoid secondary damage, and enhance The effect of tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Prepare the restorative:

[0029] First, heat the base asphalt to 130-180°C, according to the mass ratio of base asphalt 65-75%, modifier 8-10%, solvent oil 15-20%, plasticizer 3-5%, add SBS modification in sequence Extract the oil and phthalates from the neutralizing agent, furfural, stir and mix for 60-70 minutes, after stirring evenly, use a colloid mill to grind twice to make a repair agent for use.

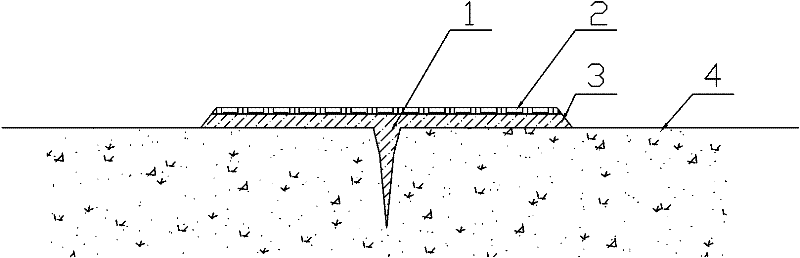

[0030] To repair the cracks on the pavement, the specific steps are as follows: refer to the attached figure 1 Shown:

[0031] Firstly, pretreatment of pavement cracks: use a hot air gun to dry the moisture in the pavement crack 1, and at the same time clean the dust and dirt inside and on both sides of the pavement crack 1. The hot air gun adopts electric heating, avoiding the traditional gas-fired The temperature of the hot air gun cannot be adjusted, and it is easy to scorch the asphalt pavement with an open flame. The hot air pressure of the hot air gun is 3~4kg...

Embodiment 2

[0036] Restoration agent components and mass ratio are as follows: base asphalt 75-85%, modifier 5-7%, solvent oil 10-15%, plasticizer 2-3%, among them, the modifier is SBR modifier , choose diesel oil or kerosene as solvent oil, and choose phthalate as plasticizer.

[0037] According to the actual situation of the cracks on the pavement, the repair agent is poured into the cracks with a joint filling machine, and the thickness of the repair agent layer 3 after filling and scraping is 1-2 mm.

[0038] A composite fiber cloth 2 is attached to the surface of the filled restoration agent layer 3. The composite fiber cloth 2 adopts a composite structure of non-woven fabric and glass fiber cloth, the lower layer is glass fiber cloth, and the upper layer is non-woven fabric. The double-layer composite structure can be further strengthened Tensile properties of composite fiber cloth. The sealing width of the composite fiber cloth 2 is 7-10 cm.

[0039] Other structures and technolo...

Embodiment 3

[0041] Restoration agent components and mass ratio are as follows: base asphalt 80-90%, modifier 3-5%, solvent oil 3-10%, plasticizer 1-2%, among which, the modifier is PE modifier , The solvent oil is selected from aromatic oil or coal tar, and the plasticizer is selected from phthalates.

[0042] Fill the heated repairing agent into the pavement crack 1 with a joint filling machine, and attach a composite fiber cloth 2 on the surface of the filled repairing agent layer 3, and the composite fiber cloth 2 adopts a double layer of non-woven fabric and polyester fiber cloth Composite structure, the lower layer is polyester fiber cloth, and the upper layer is non-woven fabric, so as to further enhance the tensile performance of the composite fiber cloth. The sealing width of the composite fiber cloth 2 is 3-5 cm.

[0043] Other structures and technological process are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com