Multifunctional agricultural thin film and preparation method thereof

An agricultural film and multi-functional technology, applied in the direction of plant protection cover, etc., can solve the problems of affecting the light transmission performance of agricultural film, reducing the yield of crops, and the use effect is not obvious, so as to expand the scope of use, the preparation method is simple and efficient, and solve the problem of environmental Problems and Effects on Ecological Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

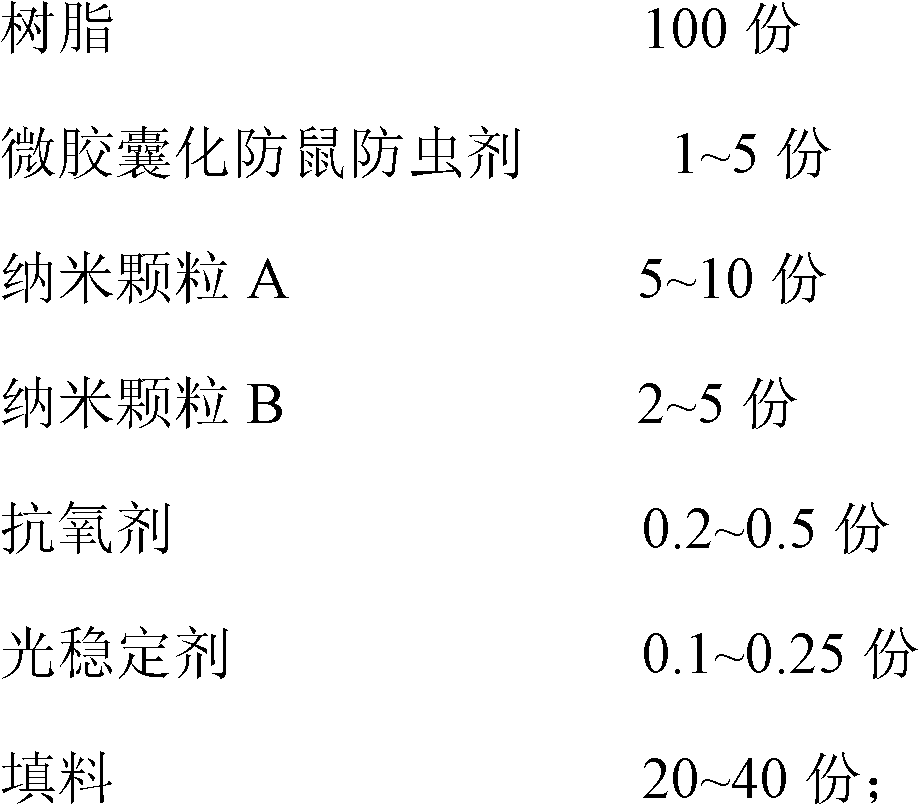

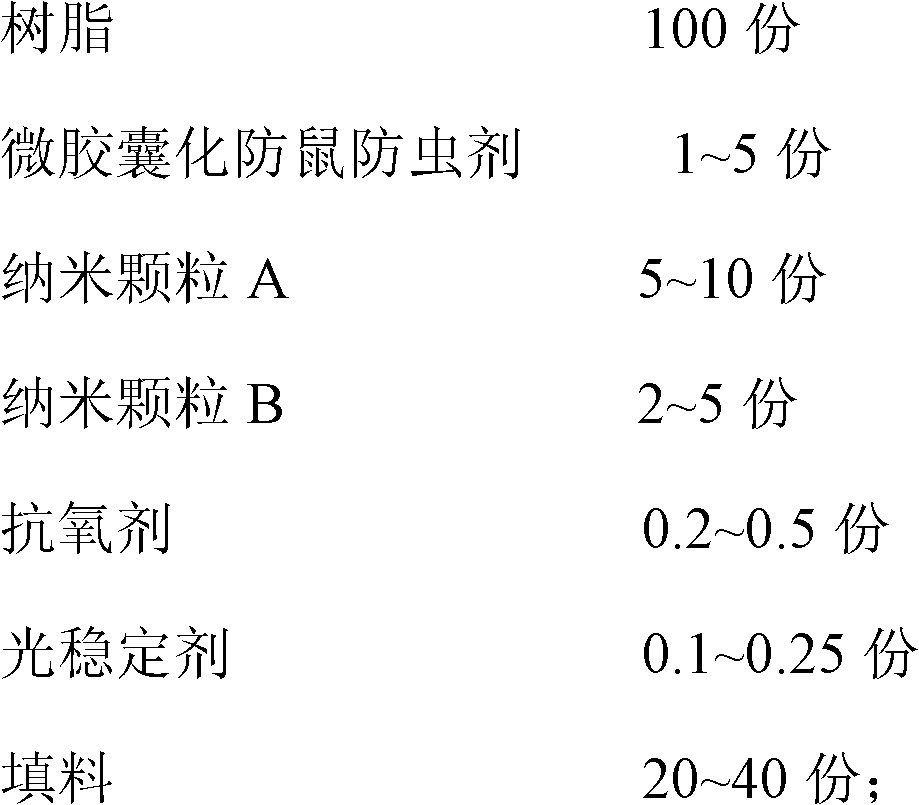

Method used

Image

Examples

Embodiment 1

[0033] (1) Weigh 0.5 g of Si-69 coupling agent, add it to 49.5 g of titanium dioxide with a particle size of 45 nm, and mix in a mixer at 100° C. to obtain modified nanoparticles A;

[0034] (2) Weigh 0.6 g of titanate coupling agent, add it to 19.4 g of tin dioxide with a particle size of 70 nm, and mix in a mixer at 90° C. to obtain modified nanoparticles B;

[0035] (3) Nanoparticle A modified in step (1) and nanoparticle B modified in step (2) with 1000g polyethylene particles, 50g capsaicin microcapsules, antioxidant 10102g, dibasic lead sulfate 2.5g and 400g of calcium carbonate are mixed in a mixer;

[0036] (3) The mixture obtained in step (2) was extruded and granulated at 100°C.

[0037] (4) blowing the pellets obtained in step (3) at 120° C. to obtain a product.

[0038] According to GB / T 17980.68-2004, the anti-rodent performance test is carried out; the anti-termite test is tested by GB / T2951.38-1986; the stain resistance is tested according to GB / T 9780-1988; t...

Embodiment 2

[0041] Adopt the same method as embodiment 1, wherein:

[0042] In the step (1), the coupling agent is a boric acid ester, and the consumption is 0.5g, 49.5g of 50 nanometers of titanium dioxide, and the temperature is 100°C; in the step (2), the coupling agent is stearic acid, and the consumption is 0.6g, The cerium oxide of 80 nanometers of 19.4g, temperature is 110 ℃; In step (3), proportioning is the polypropylene of 3000g, 30g menthyl amide microcapsules, antioxidant 26415g, tribasic lead sulfate 3g, carbonic acid Calcium 200g; extrusion granulation temperature in step (4) is extrusion under 190 DEG C; blown film temperature in step (5) is 200 DEG C.

[0043] Test Results:

[0044] performance

Embodiment 3

[0046] Adopt the same method as embodiment 1, wherein:

[0047] In step (1), the coupling agent is stearic acid, and the consumption is 6.4g, 153.6g of 30 nanometer titanium dioxide, and the temperature is 110°C; in the step (2), the coupling agent is titanate, and the consumption is 2g, 49g The cerium oxide of 38 nanometer calcium carbonate of 50 nanometers of tin dioxide and 49g, temperature is 120 ℃; In step (3), proportioning is the polyethylene of 2500 parts, 35g menthyl amide microcapsules, 35g capsaicin microcapsules, Antioxidant CA 7g, tribasic lead sulfate 6g, calcium carbonate 700g; Extrusion granulation temperature in step (4) is extruding under 125 ℃; Blowing film temperature in step (5) is 175 ℃.

[0048] Test Results:

[0049] performance

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com