Method for preparing hollow spindle-shaped micro-structured zinc oxide

A micron-structured, spindle-shaped technology, applied in the field of preparation of micron semiconductor material zinc oxide, can solve problems such as ZnO not seen, and achieve the effects of environmental friendliness, high yield and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

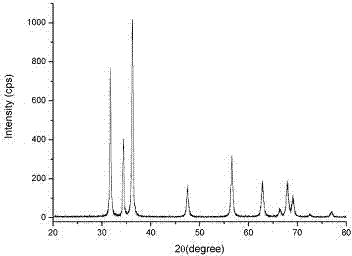

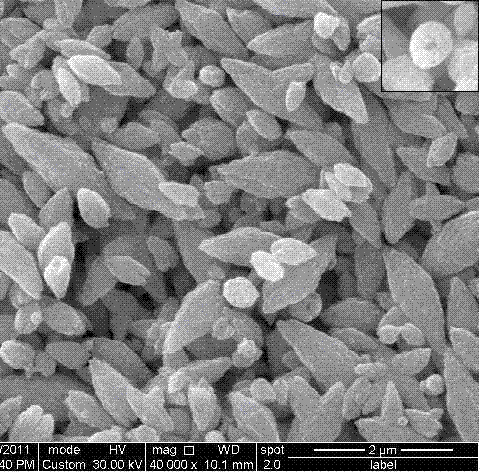

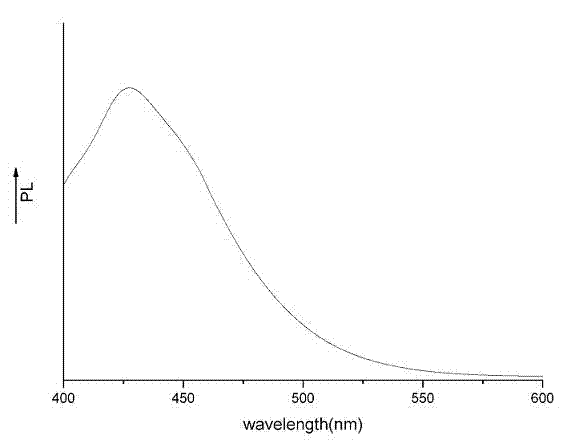

Image

Examples

Embodiment 1

[0023] (1) Dissolve zinc acetate in deionized water, stir to dissolve completely to obtain a uniform and transparent solution, zinc

[0024] The concentration of ions is 0.01 mol / liter.

[0025] (2) Add 0.1g of sodium borohydride into the solution of (1), and continue stirring for 10 minutes.

[0026] (3) Preheat the solution obtained in step (2) at 40°C for 50 minutes.

[0027] (4) Transfer the solution of (3) into a hydrothermal synthesis reactor and heat at 60°C for 10h.

[0028] (5) After step (4), cool down to room temperature naturally.

[0029] (6) Filter the solution obtained in step (5), collect the product, wash, and dry to obtain a spindle-shaped

[0030] structure of micron ZnO.

Embodiment 2

[0032] (1) Dissolve zinc acetate in deionized water, stir to dissolve completely to obtain a homogeneous transparent solution, the concentration of zinc ions is 0.01 mol / liter.

[0033] (2) Add 0.2g of sodium borohydride into the solution of (1), and continue stirring for 10 minutes.

[0034] (3) Preheat the solution obtained in step (2) at 60°C for 40 minutes.

[0035] (4) Transfer the solution of (3) into a hydrothermal synthesis reactor and heat at 60°C for 20h.

[0036] (5) After step (4), cool down to room temperature naturally.

[0037] (6) Filter the solution obtained in step (5), collect the product, wash, and dry to obtain a spindle-shaped

[0038] structure of micron ZnO.

Embodiment 3

[0040] (1) Dissolve zinc acetate in deionized water, stir to dissolve completely to obtain a homogeneous transparent solution, the concentration of zinc ions is 0.01 mol / liter.

[0041] (2) Add 0.2g of sodium borohydride into the solution of (1), and continue to stir for 1h.

[0042] (3) Preheat the solution obtained in step (2) at 60°C for 30 minutes.

[0043] (4) Transfer the solution of (3) into a hydrothermal synthesis reactor and heat at 120°C for 10h.

[0044] (5) After step (4), cool down to room temperature naturally.

[0045] (6) Filter the solution obtained in step (5), collect the product, wash, and dry to obtain a spindle-shaped

[0046] structure of micron ZnO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com