Method for preparing complete nutrient bioorganic fertilizer from wastes of biological environment-friendly pig-raising industry and product

A bio-organic fertilizer and bio-environmental protection technology, which is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, organic fertilizers, etc., can solve the problems of single nutrient content, etc., and achieve the effects of increasing crop yield, reducing fertilization work intensity, and complete nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

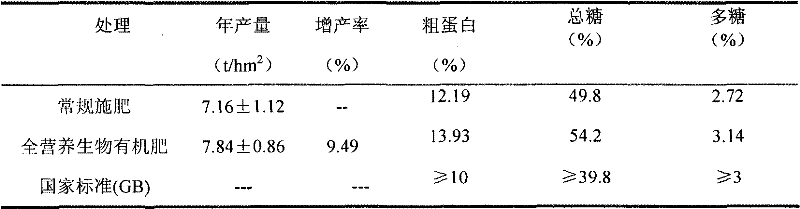

[0027] Embodiment 1: the impact of full-nutrition bio-organic fertilizer of the present invention on wine grape yield and quality

[0028] The fertilizer was field tested on 5-year-old wine grapes in Huibin wine grape (variety: Shira) production base in Yongning County, Ningxia, using the same amount (in terms of pure nutrient content) of full-nutrient bio-organic fertilizer and conventional fertilization by local farmers for wine making Grape yield and quality comparison test: Treatment 1 is routine fertilization by farmers as the control group, and the routine fertilization by farmers is N 850kg / hm 2 , P 2 o 5 300kg / hm 2 , K 2 O450kg / hm 2 ; Processing 2 is to use the full-nutrition type bio-organic fertilizer of the present invention; the area of the test plot is 10 * 3m 2 , each treatment was repeated three times, except for the test fertilizer, other agronomic measures and other field management were the same in each plot.

[0029]The results in Table 2 show that t...

Embodiment 2

[0032] Embodiment 2: the influence of total nutritional bio-organic fertilizer of the present invention on the yield and quality of Lycium barbarum

[0033] The fertilizer was set up in Ningxia in the wolfberry production base of Kangtan Village, Zhouta Township, Zhongning County. The field test wolfberry (variety: Ninggou No. 1) was used. Fertilization for the comparison test of wolfberry yield and quality: Treatment 1 is routine fertilization by farmers as the control group, and the annual fertilization amount of wolfberry is N 900kg / hm 2 , P 2 o 5 600kg / hm 2 , K 2 O 450kg / hm 2 Treatment 2 is to use the full-nutrition bio-organic fertilizer of the present invention; each treatment selects 10 plants, equivalent to an area of 20m 2 , repeat 3 times. Three repetitions were set for each treatment, and the other agronomic measures and other field management were the same in each plot except for the test fertilizer.

[0034] Table 3. The effect of total nutritional bio-or...

Embodiment 3

[0037] Embodiment 3: the impact of the full-nutrition bio-organic fertilizer of the present invention on the yield and quality of facility cucumbers

[0038] The fertilizer was tested on cucumbers in the third-generation solar greenhouse of the "Lingxian" facility vegetable production base in Yongning County, Ningxia. The same amount (in terms of pure nutrient content) of full-nutrition bio-organic fertilizers and conventional fertilization by local farmers were used to measure the yield and yield of cucumbers. Quality comparison test: Treatment 1 is routine fertilization by farmers as the control group, and the routine fertilization by farmers is N 800kg / hm 2 , P 2 o 5 500kg / hm 2 , K 2 O 800kg / hm 2 ; Processing 2 is to use the full nutrient biotype fertilizer of the present invention; its test results are shown in Table 4. As can be seen from Table 4: compared with conventional fertilization by farmers, the yield of cucumbers increased by 28.50%, the content of vitamin C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com