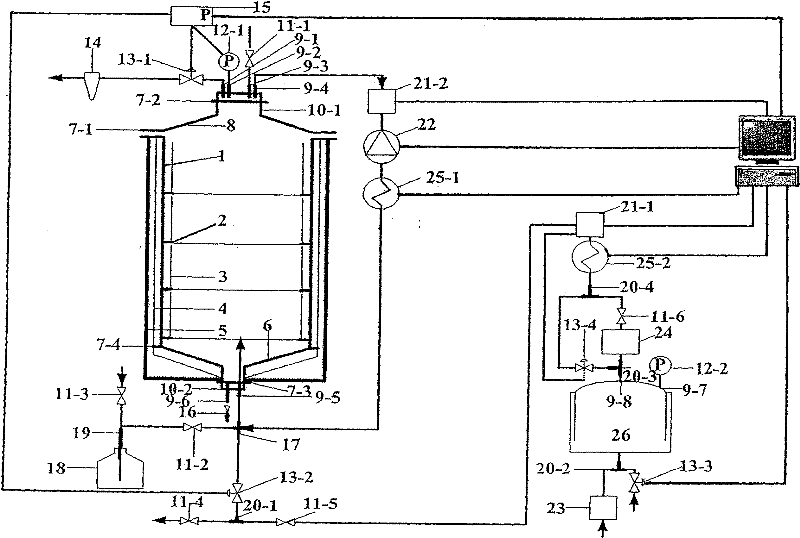

Multifunctional solid state fermentation reactor

A solid-state fermentation and reactor technology, which is applied in the field of solid-state fermentation reactors, can solve problems such as uneven microbial growth, water loss, and complex product extraction, and achieve sufficient ventilation and oxygen supply to prevent hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] refer to figure 1 , make a multifunctional solid-state fermentation reactor of the present invention. The pressure control module 15 used in this embodiment is a pressure liquid level transmitter purchased on the market (Kunlun Coastal Sensing Technology Center, outputting 4-20mA standard signal), and the data is sent to the control center. The first gas analysis module 21-1 and the second gas analysis module 21-2 are composed of intelligent oxygen probe and gas transmitter (Shanghai Shengtaike Instrument Co., Ltd.), common temperature and humidity probe and transmitter, eSENSE-K type CO2 It consists of a probe and a transmitter, which can be realized by professional technicians, and the collected data is sent to the control center. The speed-regulating air pump 22 is an XGB18-130B type air pump. Both the first heat exchanger 25-1 and the second heat exchanger 25-2 are stainless steel gas buffer tanks with coiled tubes, the gas goes outside the coiled tubes, and the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com