Method for cumulatively producing Sirolimus by using streptomyces hygroscopicus

A technology of Streptomyces hygroscopicus and sirolimus, which is applied in the field of sirolimus production, can solve the problems of long fermentation period, many intermediate products, high-concentration products and substrate inhibition, and achieve the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

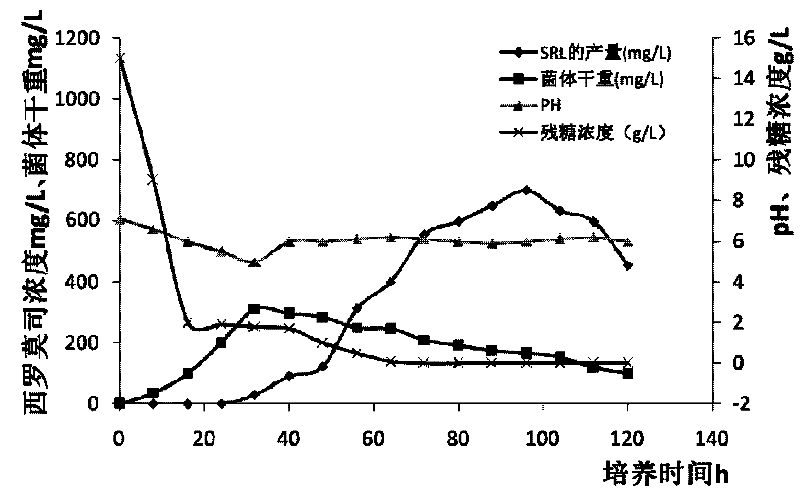

Image

Examples

Embodiment 1

[0024] The slant was cultured in ISP3 medium for 9 days and placed in a 4°C refrigerator to store the slant. Get the slant seeds and use 20% glycerol to elute the spores to form a spore suspension, and 2wt% is inoculated into the seed shake flask medium (g / L): glucose (C 6 h 12 o 6 ·H 2 O) 10.0, peptone (Peptone) 6.0, yeast extract (Yeast Extract) 6.0, casein hydrolyzate (casamino acid) 1.5, magnesium sulfate (MgSO 4 ·7H 2 O) 0.25, dipotassium hydrogen phosphate (K 2 HPO 4 ) 1.0, pH 7.0. Activation culture at 30°C for 60h, inoculated into 7L fermenter according to 6wt% inoculation amount. The optimized fermentation medium (g / L) was used in the initial stage of fermentation: glucose (Glucose) 15.0, glycerol (Glycerol) 10.0, soybean cake powder (Soybean) 10.0, yeast extract (Yeast Extract) 6.0, peptone (Peptone) 2.0, phosphoric acid Potassium dihydrogen (KH 2 PO 4 )5.0, dipotassium hydrogen phosphate (K 2 HPO 4 ) 5.0, sodium chloride (NaCL) 5.0, L-lysine (L-Lysine) 1....

Embodiment 2

[0028] The slant was cultured in ISP3 medium for 9 days and placed in a 4°C refrigerator to store the slant. Get the slant seeds and use 20% glycerol to elute the spores to form a spore suspension, and 2wt% is inoculated into the seed shake flask medium (g / L): glucose (C 6 h 12 o 6 ·H 2 O) 10.0, peptone (Peptone) 6.0, yeast extract (Yeast Extract) 6.0, casein hydrolyzate (casamino acid) 1.5, magnesium sulfate (MgSO 4 ·7H 2 O) 0.25, dipotassium hydrogen phosphate (K 2 HPO 4 ) 1.0, pH 7.5. Activation culture at 30°C for 60 hours, inoculate 6 wt% of the inoculum into a 7L fermenter based on the volume of the medium. The optimized fermentation medium (g / L) was used in the initial stage of fermentation: glucose (Glucose) 15.0, glycerol (Glycerol) 10.0, soybean cake powder (Soybean) 10.0, yeast extract (Yeast Extract) 6.0, peptone (Peptone) 2.0, phosphoric acid Potassium dihydrogen (KH 2 PO 4 )5.0, dipotassium hydrogen phosphate (K 2 HPO 4 ) 5.0, sodium chloride (NaCL) 5....

Embodiment 3

[0031] The slant was cultured in ISP3 medium for 9 days and placed in a 4°C refrigerator to store the slant. Get the slant seeds and use 20% glycerol to elute the spores to form a spore suspension, and 2wt% is inoculated into the seed shake flask medium (g / L): glucose (C 6 h 12 o 6 ·H 2 O) 10.0, peptone (Peptone) 6.0, yeast extract (Yeast Extract) 6.0, casein hydrolyzate (casamino acid) 1.5, magnesium sulfate (MgSO 4 ·7H 2 O) 0.25, dipotassium hydrogen phosphate (K 2 HPO 4 ) 1.0, pH 7.0. Activation culture was carried out at 30°C for 60 hours, and the inoculum was inoculated into a 7L fermenter according to the inoculum size of 6wt%. The optimized fermentation medium (g / L) was used in the initial stage of fermentation: glucose (Glucose) 15.0, glycerol (Glycerol) 10.0, soybean cake powder (Soybean) 10.0, yeast extract (Yeast Extract) 6.0, peptone (Peptone) 2.0, phosphoric acid Potassium dihydrogen (KH2PO4) 5.0, dipotassium hydrogen phosphate (K 2 HPO 4 ) 5.0, sodium ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com