Manufacturing method of composite enhanced insulating section bar

A manufacturing method and composite technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of waste of resources, environment, no low cost, low value, etc., to avoid environmental pollution and cheap raw materials , the effect of strong load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

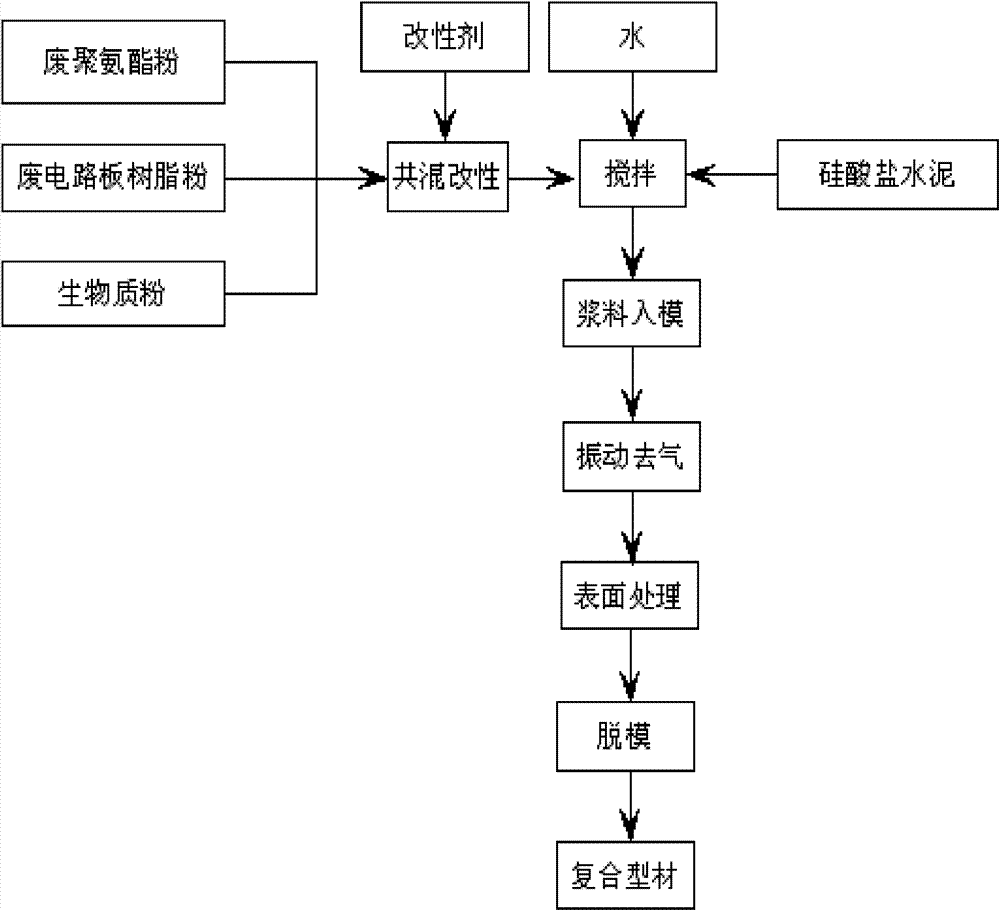

[0039] see figure 1 Prepare waste circuit board resin powder with a mass fraction of 65% in the particle size range of 2 to 5 mm, a mass fraction of 25% polyurethane powder in the particle size range of 1 to 20 mm and a mass percentage of 10% in the particle size range of 1 to 10 mm The sawdust powder is fully mixed in the mixer, and the stearic acid accounting for 5% of the weight of the mixed material is added for blending modification; the modified mixed non-metallic material is fully mixed with the cement powder according to the mass percentage of 80%, and added A proper amount of water is stirred and mixed to form a slurry; the slurry is injected into the test mold and cast into shape; the test mold injected with the slurry is placed on a vibrator to vibrate for 5 minutes to remove air bubbles and accelerate the hydrothermal synthesis reaction of the gelling material; Scrape the surface of the slurry with a scraper; demould after 24 hours, and obtain a composite reinforce...

Embodiment 2

[0041] see figure 1 Prepare waste circuit board resin powder with a mass fraction of 85% in the particle size range of 0.5-2mm, a mass fraction of 10% polyurethane powder in the particle size range of 1-10mm and a mass percentage of 5% in the particle size range of 1-5mm fully mix the straw powder in a mixer, add titanate accounting for 3% of the weight of the mixed material for blending modification; fully mix the modified mixed non-metallic material with cement powder at a mass percentage of 70%, and add an appropriate amount of The water is stirred and mixed to form a slurry; the slurry is injected into the test mold and cast into shape; the test mold injected with the slurry is placed on a vibrator to vibrate for 3 minutes to remove air bubbles and accelerate the hydrothermal synthesis reaction of the gelling material; use a scraper Scrape the surface of the slurry; release the mold after 24 hours, and obtain a composite reinforced profile after drying.

Embodiment 3

[0043] seefigure 1 Prepare waste circuit board resin powder with a mass fraction of 60% in the particle size range of 0.5-2mm, a mass fraction of 30% polyurethane powder in the particle size range of 1-10mm and a mass percentage of 10% in the particle size range of 1-5mm The peanut shell powder is fully mixed in a mixer, and the stearic acid accounting for 1% of the weight of the mixed material is added to carry out blending modification; the modified mixed non-metallic material is fully mixed with cement powder according to 65% by mass, and added A proper amount of water is stirred and mixed to form a slurry; the slurry is injected into the test mold and cast into shape; the test mold injected with the slurry is placed on a vibrator to vibrate for 1 min to remove air bubbles and accelerate the hydrothermal synthesis reaction of the gelling material; Scrape the surface of the slurry with a scraper; demould after 24 hours, and obtain a composite reinforced profile after drying. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com