Self-crosslinking organosilicone heat-resistant coating

A heat-resistant coating, silicone technology, applied in the direction of coating, can solve the problems of poor self-drying performance, low mechanical strength, reduced silicone content, etc., and achieve the effect of good drying performance and excellent physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

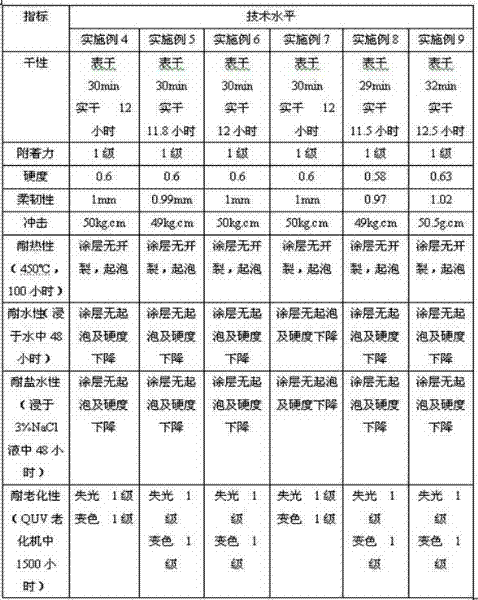

Examples

Embodiment 1

[0016] The synthetic process step of modified silicone resin of the present invention is as follows:

[0017] 1) Synthesis of acrylic acid prepolymer: take 13kg of methyl methacrylate, 20kg of styrene, 8kg of butyl acrylate, 3kg of acrylic acid, 1.3kg of benzoyl peroxide, and 45kg of xylene; Add it into the reaction kettle, raise the temperature to reflux temperature (138-140°C), mix the mixture of acrylic acid monomer, methyl methacrylate, styrene, butyl acrylate and benzoyl peroxide for 2 hours (at 2- 2.5 hours) dropwise addition; reflux for 2 hours, then cool down; when the temperature drops to 80°C, discharge the material for later use;

[0018] 2) Synthesis of organosilicon intermediates: Take 15kg of phenyltrichlorosilane, 8kg of dimethyldichlorosilane, 35kg of toluene, 30kg of ethanol, and 12kg of deionized water; mix deionized water with 2 / 3 toluene is added to the hydrolysis kettle, and the mixture of phenyltrichlorosilane, dimethyldichlorosilane and the remaining 1 / ...

Embodiment 2

[0021] Synthesis of modified silicone resin of the present invention:

[0022] 1) Synthesis of acrylic acid prepolymer: Take 15kg of methyl methacrylate, 25kg of styrene, 10kg of butyl acrylate, 5kg of acrylic acid, 1.5kg of benzoyl peroxide, and 50kg of xylene; add xylene In the reaction kettle, heat up to the reflux temperature (138-140°C), and add the mixture of acrylic acid monomer, methyl methacrylate, styrene, butyl acrylate and benzoyl peroxide dropwise in 2.5 hours; reflux Keep warm for 2 hours, then cool down; when the temperature drops to 80°C, discharge the material for later use;

[0023]2) Synthesis of organosilicon intermediates: Take 20kg of phenyltrichlorosilane, 10kg of dimethyldichlorosilane, 40kg of toluene, 35kg of ethanol, and 15kg of deionized water; mix deionized water with Add 2 / 3 toluene into the hydrolysis kettle, drop the mixture of phenyltrichlorosilane, dimethyldichlorosilane and the remaining 1 / 3 toluene from the high position tank, control the f...

Embodiment 3

[0026] Synthesis of modified silicone resin of the present invention:

[0027] 1) Synthesis of acrylic acid prepolymer: Take 12kg of methyl methacrylate, 15kg of styrene, 5kg of butyl acrylate, 1kg of acrylic acid, 1kg of benzoyl peroxide, and 40kg of xylene; add xylene Into the reaction kettle, heat up to the reflux temperature (138-140°C), add the mixture of acrylic acid monomer, methyl methacrylate, styrene, butyl acrylate and benzoyl peroxide dropwise in 2.2 hours; reflux Keep warm for 2 hours, then cool down; when the temperature drops to 80°C, discharge the material for later use;

[0028] 2) Synthesis of organosilicon intermediates: take 10kg of phenyltrichlorosilane, 5kg of dimethyldichlorosilane, 20kg of toluene, 20kg of ethanol, and 5kg of deionized water; mix deionized water with 2 / 3 toluene is added to the hydrolysis kettle, and the mixture of 1-phenyltrichlorosilane, dimethyldichlorosilane and the remaining 1 / 3 toluene is added dropwise from the high position tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com