Method for continuously forming silicon carbide coating on surfaces of carbon fibers

A silicon carbide coating and carbon fiber technology, which is applied in the chemical characteristics of fibers, coatings, electrolytic coatings, etc., can solve the problems of continuous processing of difficult-to-long fibers, expensive reaction equipment, poor coating uniformity, etc., and the bonding force is not easy to fall off , Easy to operate, good binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

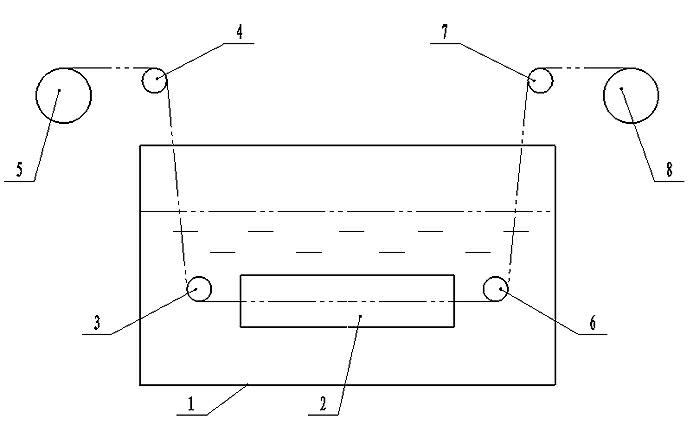

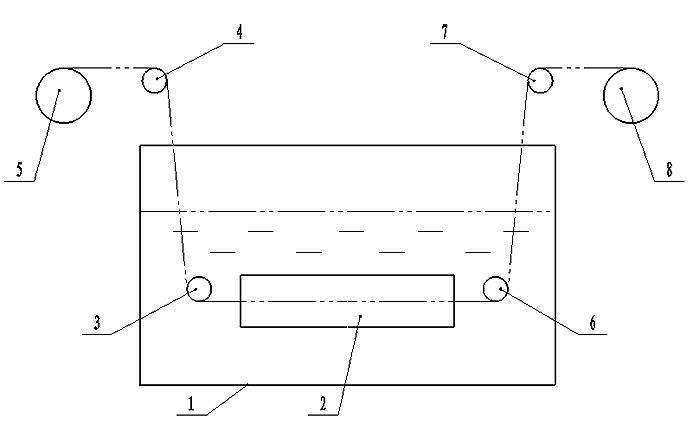

[0027] The specific embodiments will be further described with reference to the schematic structural diagram of the electrophoretic device in the accompanying drawings.

[0028] Take 50 grams of carbon nano-silicon particles and add them to 1000 grams of water. After ultrasonic treatment for 0.5 hours, add 1.05 grams of ethylenediamine and stir for 2 hours to obtain silicon carbide electrophoretic fluid; cm, the outer diameter is 5 cm, and the graphite tube 2 with a length of 30 cm redirects the carbon fiber from the pay-off wheel 5 arranged on the electric swimming pool 1 top through the first lead-in wheel 4 and the second lead-in wheel 3, so that the carbon fiber changes direction from the graphite One end of the tube 2 enters, passes through the other end of the graphite tube 2, and then passes through the first lead-out wheel 6 and the second lead-out wheel 7 to redirect, and fixes the front end of the carbon fiber on the take-up wheel 8; then pours the silicon carbide ele...

Embodiment 2

[0031]Take 3 grams of silicon carbide nanowires, add them to 3000 grams of isopropanol, and after ultrasonic treatment for 0.5 hours, add 4 grams of n-butylamine and ultrasonic for 2 hours to obtain silicon carbide electrophoretic fluid; 6 cm, the outer diameter is 10 cm, and the length is 60 cm graphite tube 2, then the carbon fiber is installed on the electrophoresis device (the method is the same as that of Example 1); The surface is located 2 cm above the graphite tube 2, and a stirring device is placed in the battery 1 at the same time, and then the positive pole of the power supply with a voltage of 100V is connected to the graphite tube 2, and the negative pole is connected to the carbon fiber, and the graphite tube 2 is used as the anode, and the carbon fiber is used as the cathode; turn on the stirring The device mixes the silicon carbide electrophoretic liquid, connects the power supply, and starts the traction motor, so that the carbon fiber is deposited in the cente...

Embodiment 3

[0033] Take 100 grams of silicon carbide nanoparticles treated with strong acid, add them to 2000 grams of butanol, and after ultrasonic treatment for 1 hour, add 105 grams of elemental iodine and stir for 0.5 hours to obtain silicon carbide electrophoretic fluid; A graphite tube 2 with an inner diameter of 4 cm, an outer diameter of 8 cm, and a length of 60 cm is installed on the electrophoresis device (the method is the same as in Example 1); , so that the liquid level is located 5 cm above the graphite tube 2, and at the same time, a stirring device is placed in the battery 1, and then the positive pole of the power supply with a voltage of 150V is connected to the graphite tube 2, and the negative pole is connected to the carbon fiber, and the graphite tube 2 is used as the anode, and the carbon fiber is used as the cathode. Turn on the stirring device to mix the silicon carbide electrophoretic liquid, turn on the power supply, and start the traction motor, so that the carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com