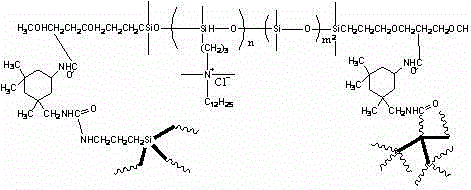

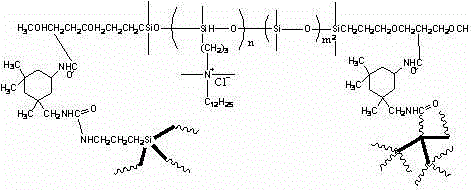

Quaternary ammonium salt modified organosilicon polyurethane ocean antifouling paint and preparation method and application thereof

A marine antifouling, quaternary ammonium salt technology, applied in the direction of polyurea/polyurethane coatings, antifouling/underwater coatings, coatings, etc. The effect of adsorption and avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) React 47.9g of chloropropylmethyldichlorosilane and 4.5g of water in the organic solvent ether for 3 hours, wash with water until neutral, dry with anhydrous calcium chloride, remove the organic solvent ether by distillation at atmospheric pressure, and distill under reduced pressure to obtain 2 ,4,6-tris(3-chloropropyl)-2,4,6-trimethyl-cyclotrisiloxane;

[0034] 2) Dissolve 40.50g of allyl glycidyl ether in toluene, add 20 μL of catalyst chloroplatinic acid, raise the temperature to 80°C, slowly add 46.85g of tetramethyldisiloxane dropwise under stirring, and continue the reaction at 120°C for 6 h Afterwards, underpressure distillation obtains 1,3-bis[3-(2,3-epoxypropoxy)propyl]-tetramethyldisiloxane;

[0035] 3) Mix 13g of 1,3-bis[3-(2,3-epoxypropoxy)propyl]-tetramethyldisiloxane and 58g of methanol, and add 20μL of trifluoromethyl under N2 protection Sulfonic acid, after reacting at 70°C under reflux for 6 hours, adjust the pH to 7, continue the reaction for 1 ho...

Embodiment 2

[0040] 1) React 47.9g of chloropropylmethyldichlorosilane and 18g of water in the organic solvent ether for 3 hours, wash with water until neutral, dry with anhydrous calcium chloride, remove the organic solvent ether by distillation at atmospheric pressure, and distill under reduced pressure to obtain 2, 4,6-tris(3-chloropropyl)-2,4,6-trimethyl-cyclotrisiloxane;

[0041] 2) Dissolve 40.50g of allyl glycidyl ether in toluene, add 20 μL of catalyst chloroplatinic acid, raise the temperature to 80°C, slowly add 46.85g of tetramethyldisiloxane dropwise under stirring, and continue the reaction at 120°C for 6 h Afterwards, underpressure distillation obtains 1,3-bis[3-(2,3-epoxypropoxy)propyl]-tetramethyldisiloxane;

[0042] 3) Mix 13g of 1,3-bis[3-(2,3-epoxypropoxy)propyl]-tetramethyldisiloxane and 58g of methanol, and add 20μL of trifluoromethyl under N2 protection Sulfonic acid, after reacting at 70°C under reflux for 6 hours, adjust the pH to 7, continue the reaction for 1 hou...

Embodiment 3

[0047] 1) React 47.9g of chloropropylmethyldichlorosilane and 18g of water in the organic solvent ether for 3 hours, wash with water until neutral, dry with anhydrous calcium chloride, remove the organic solvent ether by distillation at atmospheric pressure, and distill under reduced pressure to obtain 2, 4,6-tris(3-chloropropyl)-2,4,6-trimethyl-cyclotrisiloxane;

[0048] 2) Dissolve 40.50 g of allyl glycidyl ether in toluene, add 20 μL of catalyst chloroplatinic acid, raise the temperature to 80 °C, slowly add 20.30 g of tetramethyldisiloxane dropwise under stirring, and continue the reaction at 120 °C for 6 h Afterwards, underpressure distillation obtains 1,3-bis[3-(2,3-epoxypropoxy)propyl]-tetramethyldisiloxane;

[0049] 3) Mix 13g of 1,3-bis[3-(2,3-epoxypropoxy)propyl]-tetramethyldisiloxane and 58g of methanol, and add 20μL of trifluoromethyl under N2 protection Sulfonic acid, after reacting at 70°C under reflux for 6 hours, adjust the pH to 7, continue the reaction for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com