Negative temperature coefficient (NTC) material utilized at high temperature and preparation method thereof

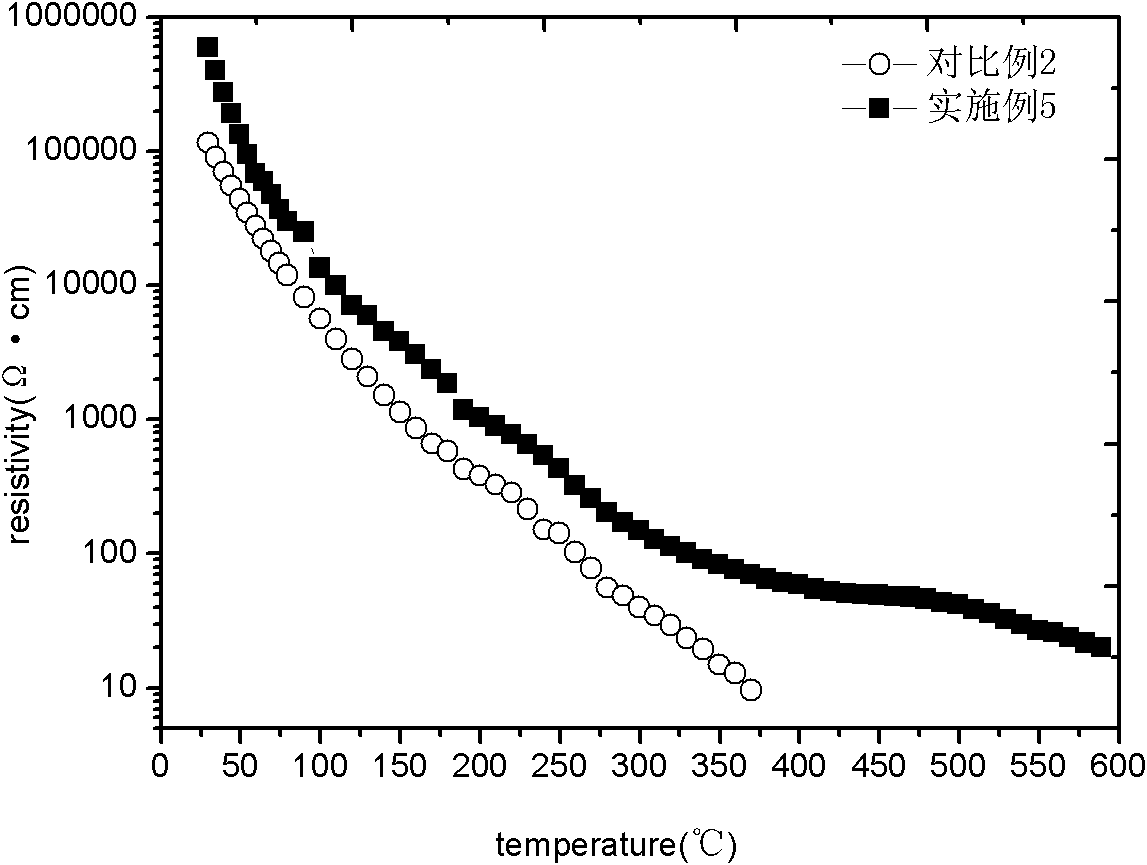

A high temperature, raw material technology, applied in the field of NTC materials and its preparation, can solve the problems of low resistivity and low resistance drift rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

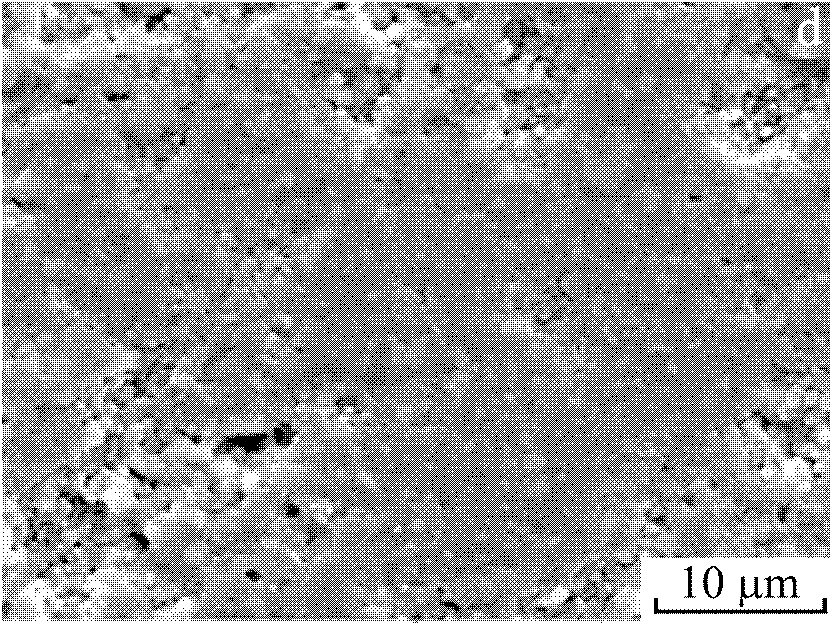

Image

Examples

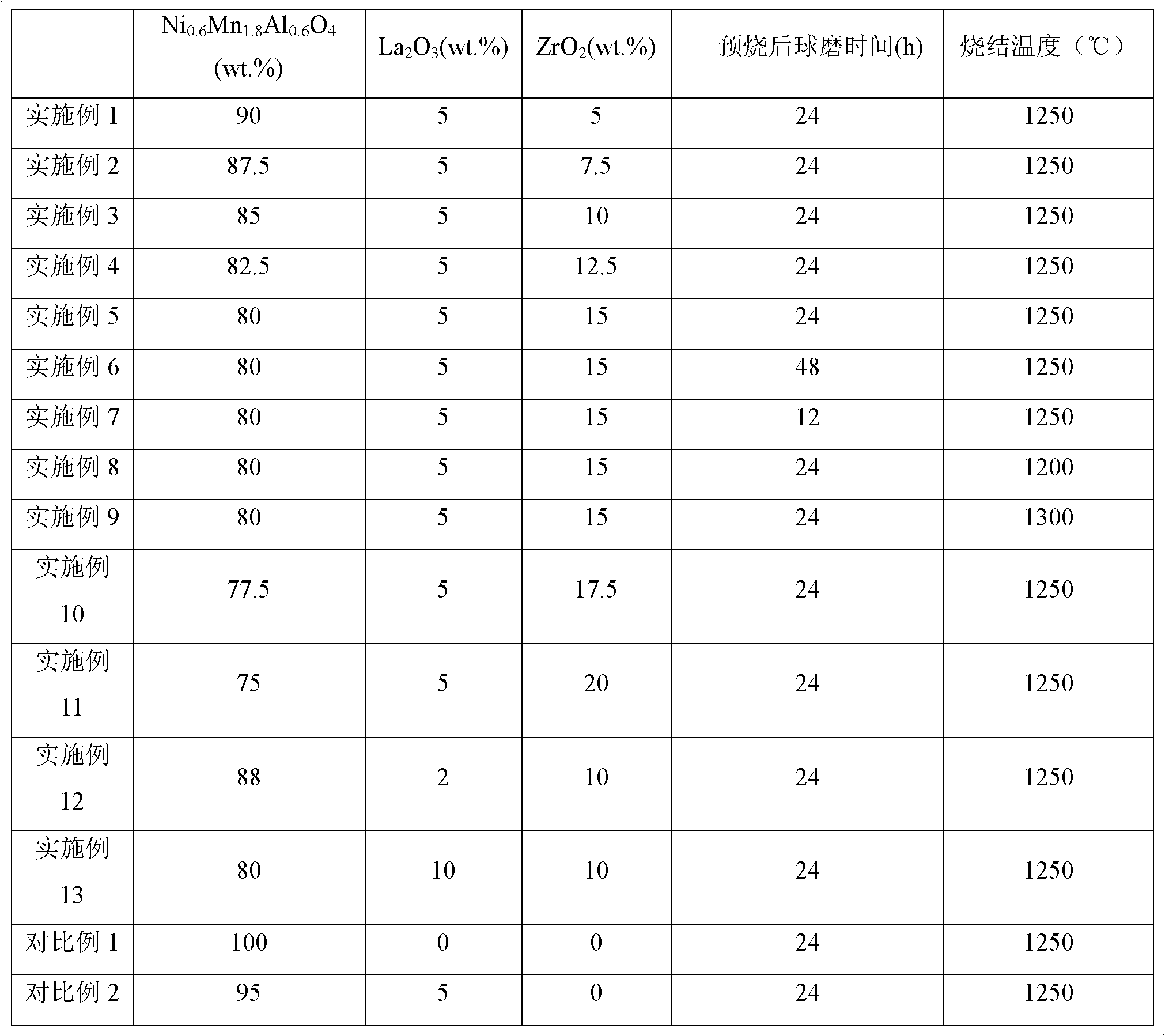

Embodiment 1

[0029] The raw material component of the present embodiment is: 5wt.% La 2 o 3 , 5wt.%ZrO 2 , the rest is Ni 0.6 mn 1.8 al 0.6 o 4 .

[0030] This embodiment includes the following steps:

[0031] Step 1, according to Ni 0.6 mn 1.8 al 0.6 o 4 Weigh the various oxide starting materials, namely MnO, at the stoichiometric molar ratios shown in 2 , NiO, Al2 o 3 , it was mixed evenly by wet ball milling, using absolute ethanol and agate balls as the ball milling medium, the volume ratio of raw materials and absolute ethanol was 1:2, the volume ratio of balls and materials was 2.5:1, and the ball milling time was controlled 8 hours, the power of the ball mill is 0.75KW;

[0032] Step 2. Ni after ball milling 0.6 mn 1.8 Al 0.6 o 4 The powder is dried, and the dried powder is pre-fired at 900°C for 3 hours in an air atmosphere, and the heating rate is 3°C / min;

[0033] Step 3, the pre-burned Ni 0.6 mn 1.8 Al 0.6 o 4 Powder and 5wt.% La 2 o 3 Powder, 5wt.%ZrO 2...

Embodiment 2

[0037] The raw material component of the present embodiment is: 5wt.% La 2 o 3 , 7.5wt.%ZrO 2 , the rest is Ni 0.6 mn 1.8 Al 0.6 o 4 .

[0038] This embodiment includes the following steps:

[0039] Step 1, according to Ni 0.6 mn 1.8 Al 0.6 o 4 Stoichiometric molar ratios shown Weighing various oxide starting materials, i.e. MnO 2 , NiO, Al 2 o 3 , it was mixed evenly by wet ball milling, using absolute ethanol and agate balls as the ball milling medium, the volume ratio of raw materials and absolute ethanol was 1:2, the volume ratio of balls and materials was 2.5:1, and the ball milling time was controlled 10 hours, the power of the ball mill is 0.75KW;

[0040] Step 2. Ni after ball milling 0.6 mn 1.8 Al 0.6 o 4 The powder is dried, and the dried powder is pre-fired at 1000° C. for 1 hour in an air atmosphere, and the heating rate is 5° C. / min.

[0041] Step 3, the pre-burned Ni 0.6 mn 1.8 Al 0.6 o 4 Powder and 5wt.% La 2 o 3 Powder, 7.5wt.%ZrO 2 Ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com