Crystal grain structure of light-emitting diode and method for manufacturing bottom electrode of crystal grain structure

A technology of light-emitting diodes and grain structures, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., and can solve the problem of deterioration in the electrical connection quality between the die-bonding glue 20 and the LED grain 10, electrical instability and gaps in LEDAssembly components, etc. problem, to achieve the effect of improving the quality of electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

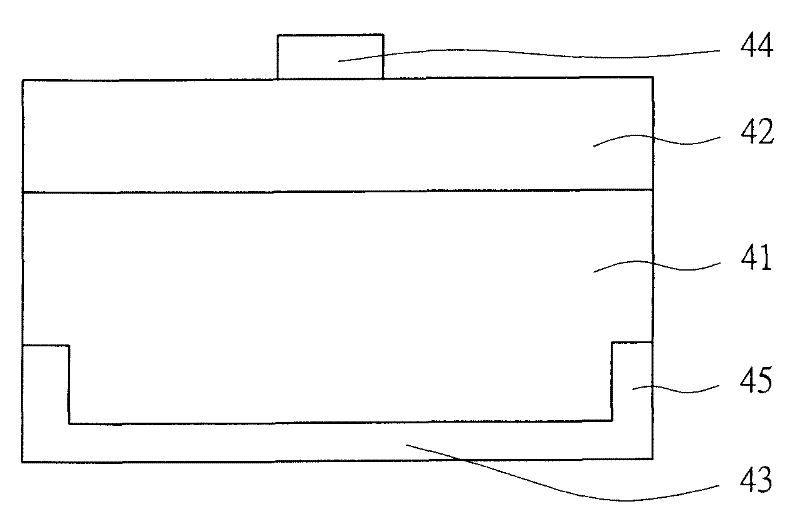

[0028] First, see image 3 , Figure 4 As shown, the light-emitting diode grain structure of the present invention includes:

[0029] a substrate 41;

[0030] a light-emitting layer 42 formed on the top surface of the substrate 41;

[0031] At least one bottom electrode 43 is formed on the bottom surface of the substrate 41;

[0032] At least one top surface electrode 44 is formed on the top surface of the light emitting layer 42;

[0033] At least one side electrode 45 is formed on the bottom side of the substrate 41 .

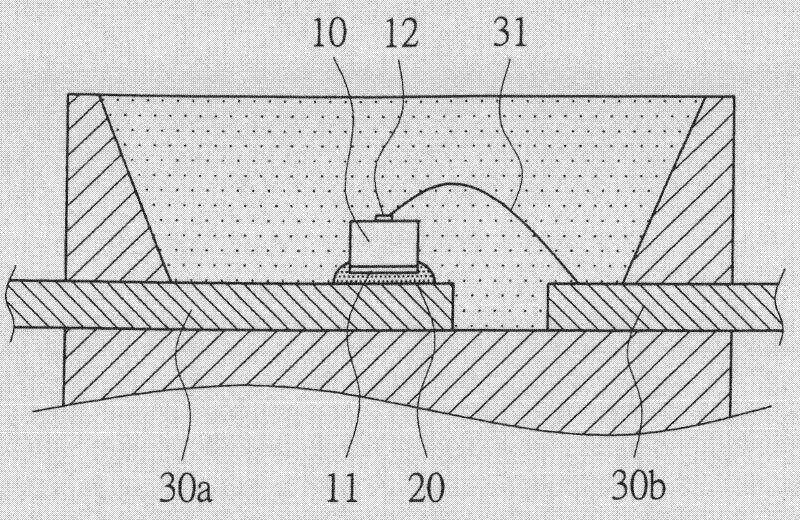

[0034] Based on the above structure, the light-emitting diode grain structure of the present invention improves the design of the electrodes. In addition to the bottom electrode 43 and the top electrode 44, a side electrode 45 of a certain height is provided at the bottom of the substrate 41; and when the package is completed Finally, the wire 31 is electrically connected to the top electrode 44 and the second lead frame 30b, and the die-bonding glue 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com