Flexible circuit conductive composition, preparation method and using method thereof

A flexible circuit and composition technology, applied in conductive pattern formation, conductive coatings, opto-mechanical equipment, etc., can solve the problems of inability to simplify the steps of nanoimprinting, inability to change the non-conductive properties of nanoimprinting compositions, etc. The effect of sintering time, reducing sintering temperature, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

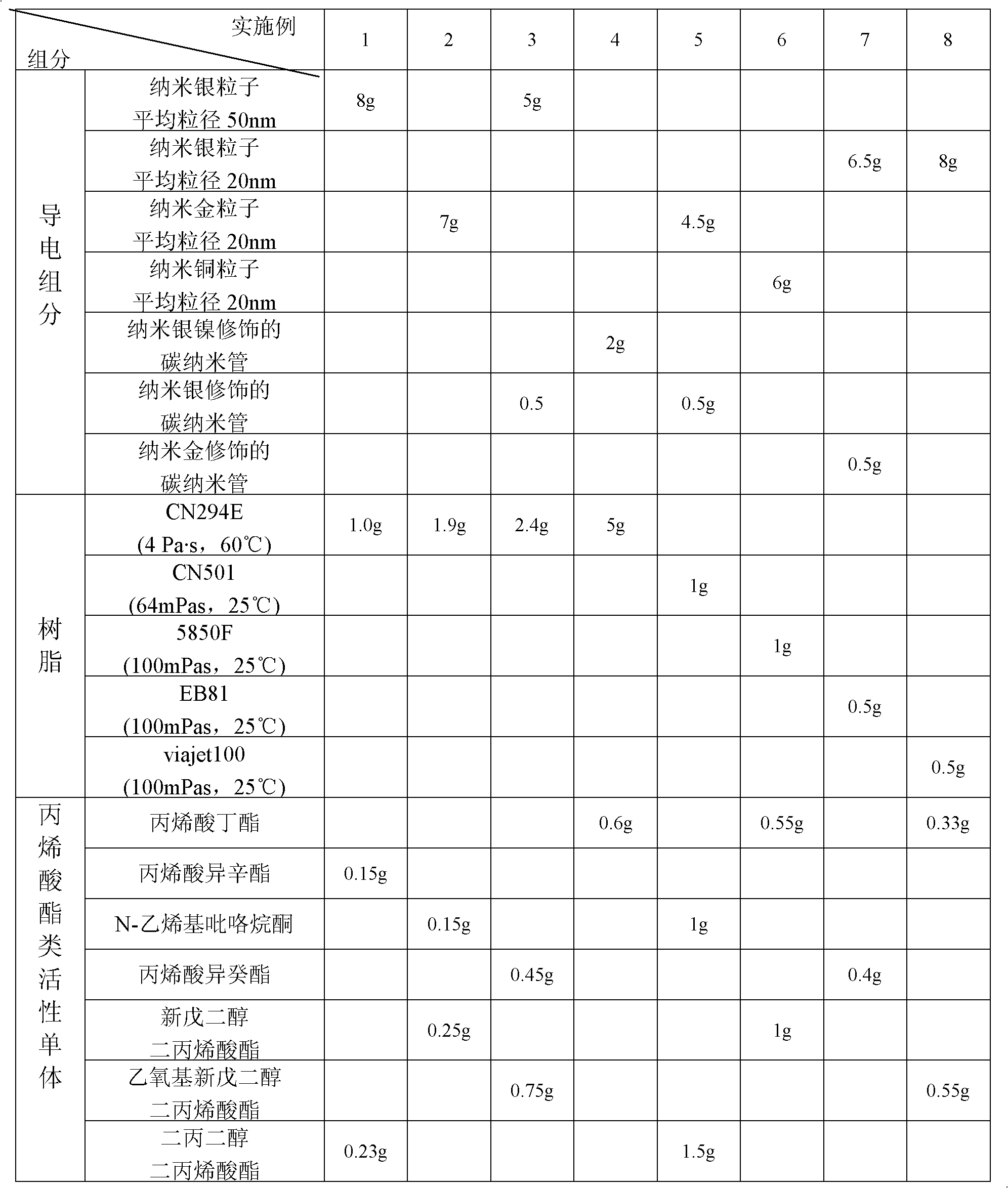

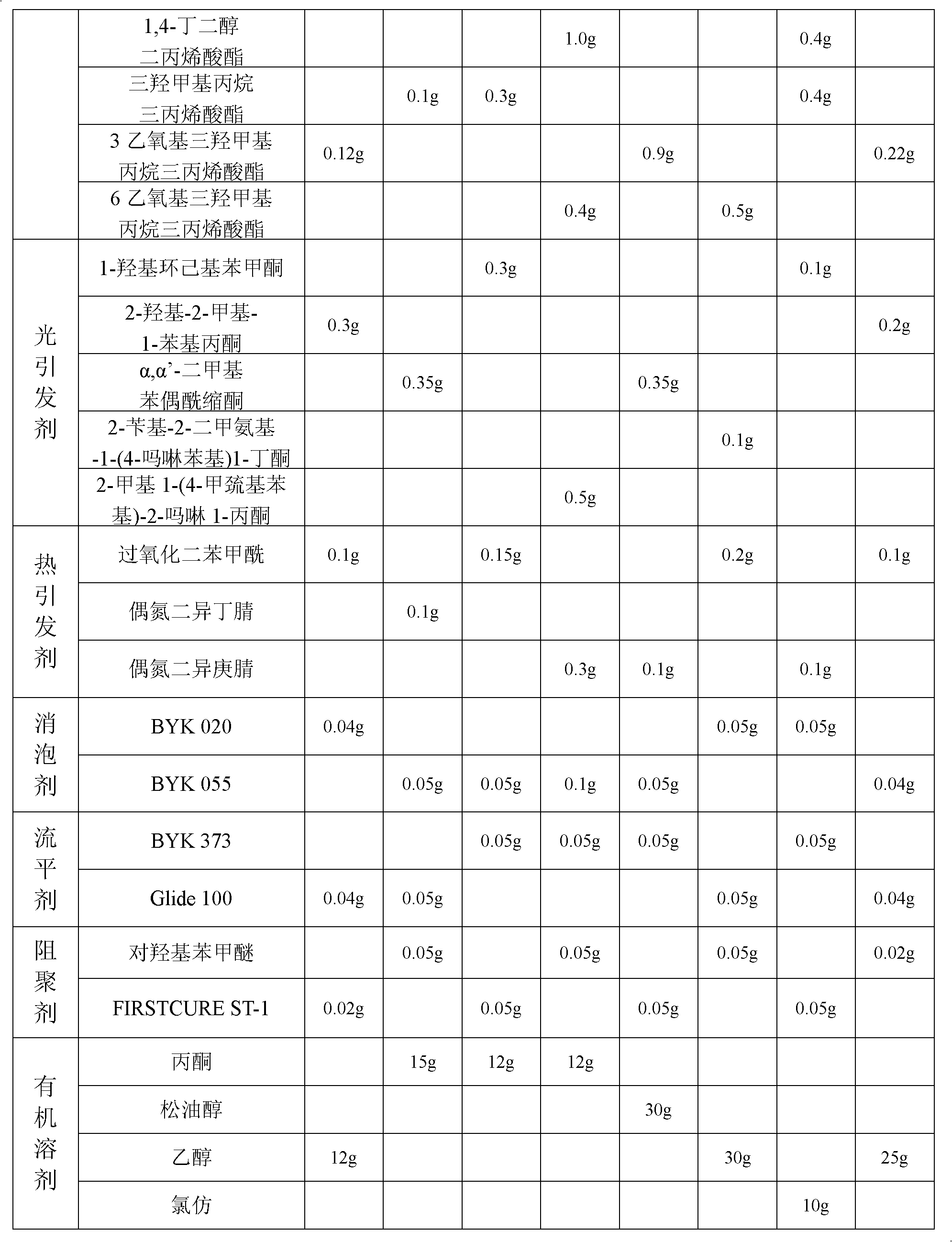

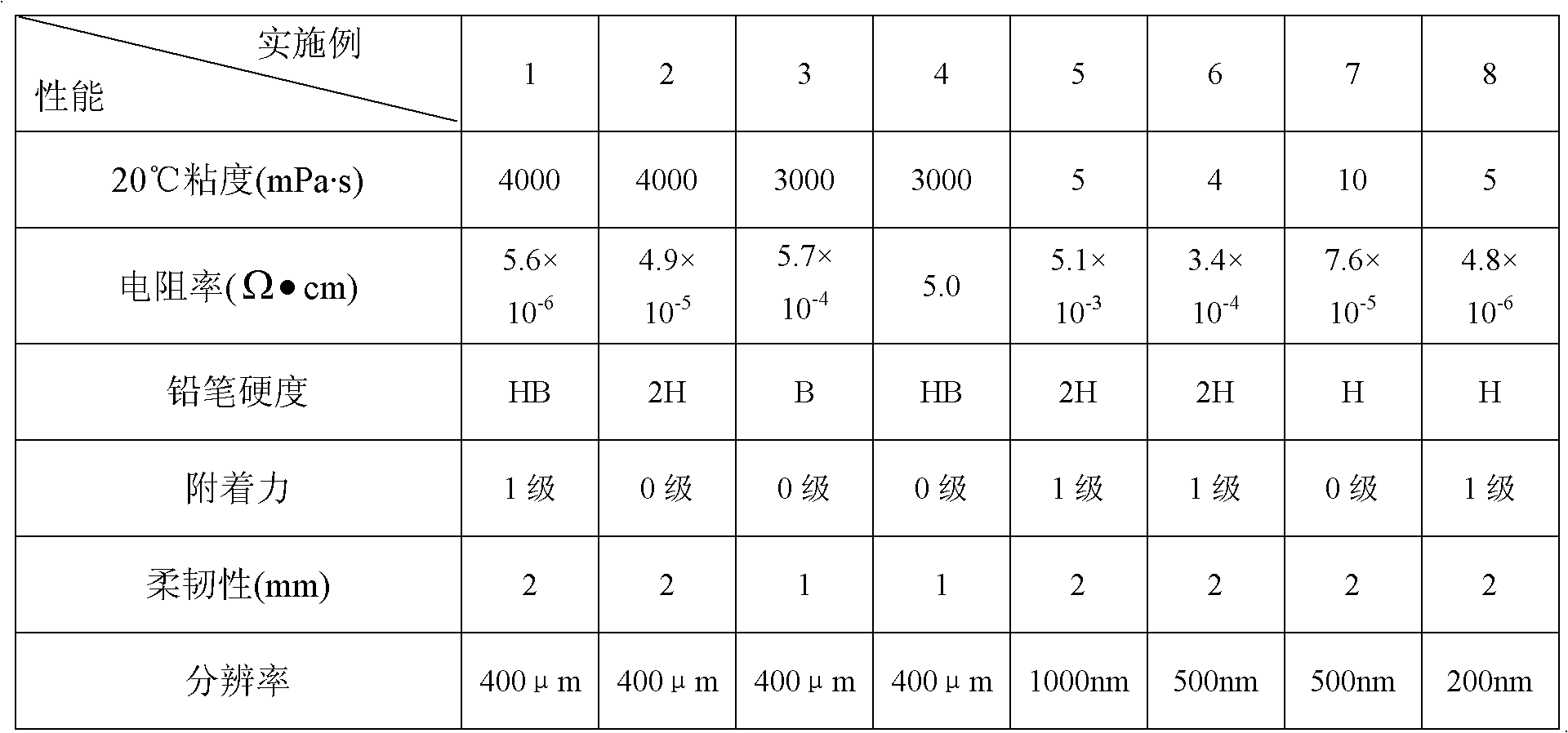

Embodiment 1

[0046] First, dissolve 8g of nano-silver powder (brand NSP-01, average particle size 50nm) in 12g of ethanol, stir evenly, and then disperse it by ultrasonic wave (brand AS5150B, frequency 55Hz) for 20 minutes, and in yellow light (filtering light with wavelength less than 420nm) Add 1.0g of polyester acrylic resin CN294E (4Pa·s, 60°C), 0.15g of isooctyl acrylate, 0.23g of dipropylene glycol diacrylate, and 0.12g of 3-ethoxytrimethylolpropane triacrylate under the conditions, Then add 0.3g of 2-hydroxy-2-methyl-1-phenylacetone, 0.1g of dibenzoyl peroxide, 0.04g of BYK 020, 0.04g of Glide 100, 10.02g of FIRSTCURE ST-10.02g, stir well and ultrasonically (brand AS5150B, frequency 55Hz) to a viscosity (20°C) of about 4Pa·s to prepare a flexible circuit conductive composition.

[0047] Print the conductive composition of the flexible circuit on the surface of the polyimide film by screen printing, expose it to a high-pressure mercury lamp (the main wavelength is 365nm) for 5min, an...

Embodiment 2

[0049] First, dissolve 7g of nano-gold powder (brand GNP01-5-100, average particle size 5nm) in 15g of acetone and disperse it by ultrasonic wave (brand AS5150B, frequency 55Hz) for 20 minutes until uniform, and then in yellow light (filtering light with wavelength less than 420nm) Under the conditions, 1.9g of polyester acrylic resin CN294E (4Pa s, 60°C), 0.15g of N-vinylpyrrolidone, 0.25g of neopentyl glycol diacrylate, 0.1g of trimethylolpropane triacrylate, α, 0.35g of α'-dimethylbenzil ketal, 0.1g of azobisisobutyronitrile, 0.05g of BYK 055, 0.05g of Glide 100, 0.05g of p-hydroxyanisole, and then ultrasonic (brand AS5150B, frequency 55Hz) to a viscosity (20°C) of about 4Pa·s to prepare a conductive composition for a flexible circuit.

[0050] The prepared flexible circuit conductive composition was printed on the surface of the polyimide film by screen printing technology, exposed to a high-pressure mercury lamp (main wavelength of 365nm) for 5min, and then placed on a te...

Embodiment 3

[0052] Preparation of nano-silver modified carbon nanotubes: first mix carbon nanotubes with ethylene glycol, ultrasonically mark it as sample 1 for 15 minutes, then mix sodium dodecylbenzenesulfonate (SDBS), polyvinylpyrrolidone (PVP) (weight ratio is SDBS / PVP / CNTs=2:2:1), silver nitrate (weight ratio is Ag:PVP:SDBS=1:1:1) is added in ethylene glycol and ultrasonically marked as sample 2 for 10 minutes, and Sample 2 is added to sample 1, ultrasonicated for 2-4 hours, filtered, and dried to obtain nano-silver modified carbon nanotubes.

[0053]5.0g nano-silver powder (brand NSP-01, average particle size 50nm), 0.5g nano-silver modified carbon nanotubes prepared by the above-mentioned method were dissolved in 12g acetone, and ultrasonic wave (brand AS5150B, frequency 55Hz) was dispersed to uniformity for 20 minutes. Add it into 2.4g of polyester acrylic resin CN294E (4Pa·s, 60°C) under the condition of yellow light (filter the light with a wavelength less than 420nm), stir well...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com