Process for manufacturing high-precision titanium and titanium alloy tube

A technology of titanium alloy tube and preparation process, which is applied in the field of titanium and titanium alloy processing, can solve the problems that the surface precision and roughness of titanium and titanium alloy tube cannot realize mirror surface, etc., and achieve low processing cost, high yield rate and excellent processing technology simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] An embodiment of the present invention is described below.

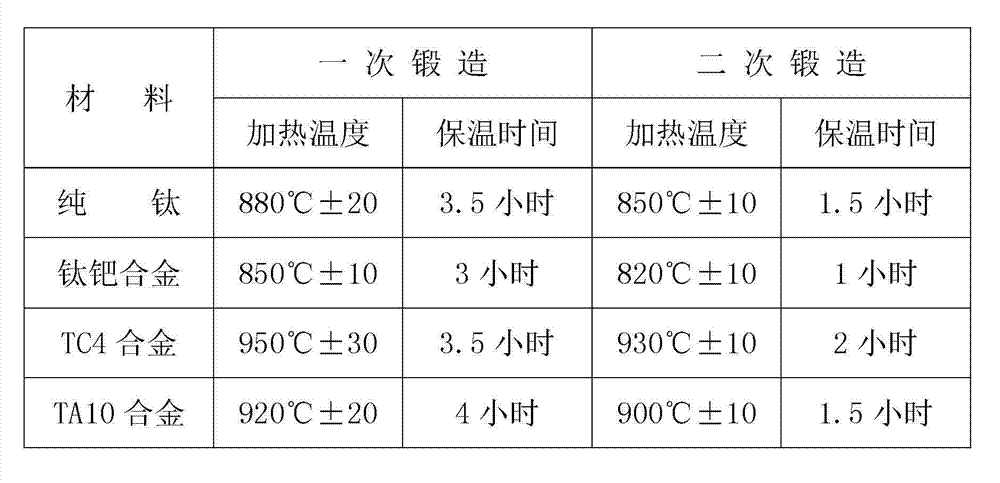

[0031] The high-precision titanium or titanium alloy tube preparation process consists of the following steps:

[0032] 1) Material selection: Industrial pure titanium sponge or titanium alloy is used as raw material. In the initial stage of production of high-precision titanium and titanium alloy tubes, strict requirements must be placed on the ingredients first. Considering that this material involves medical equipment and human body parts, industrial pure titanium sponge (ELI) is preferred to ensure the internal quality of the mirror surface material and the quality of the metal. The gap between ions and the safety of non-toxic and harmless to the human body.

[0033] 2) Smelting: In order to ensure the metallographic and physical and chemical properties of the raw materials during the smelting process, three or more ingots must be used for smelting, that is, two secondary ingot smelting are done during sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com