Method for carrying out fluidized drying on lignite by microwaves

A technology of fluidized drying and lignite, which is applied in the direction of drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of lower coal coking quality, low drying efficiency, high energy consumption, etc. The effect of large solid contact area and high energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In the method of the invention, the raw material lignite is firstly pre-dried through a microwave device with hot air through a conveying device along a horizontal direction, and then fluidized and dried through a fluidized bed device with hot air, so that the free water content of the raw material lignite reaches below 1%.

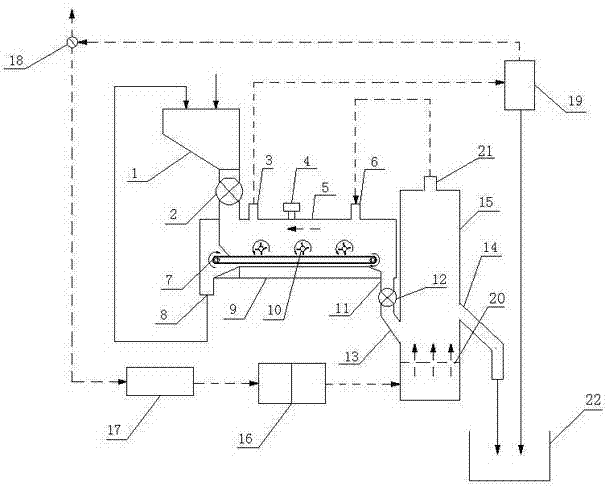

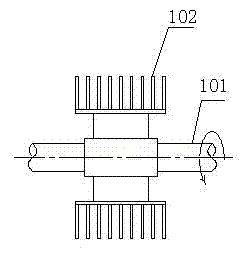

[0025] The device that the inventive method adopts is horizontal, as figure 1 As shown, the solid line arrow in the figure is the movement direction of the raw material lignite, and the dotted line arrow is the movement direction of the hot air. The raw material lignite is generally lignite with a water content of more than 20% and a particle size of less than 10mm. The raw lignite is added to the horizontal crawler conveying device 7 in the microwave device 5 through the hopper 1 of the device through the planetary feeder 2. When the raw lignite passes through the microwave device in the horizontal direction on the horizontal crawler conveying dev...

Embodiment 2

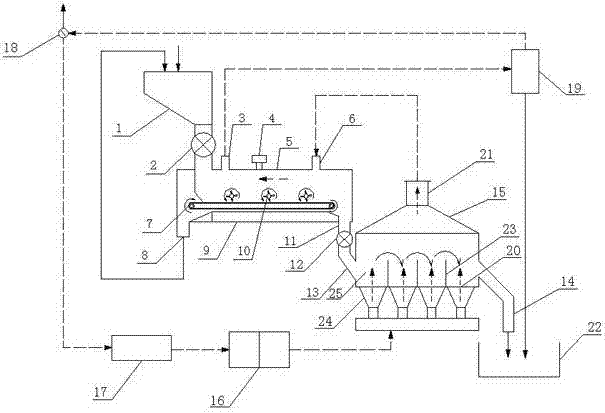

[0029] The fluidized drying device in embodiment 1 can also adopt horizontal fluidized bed, as image 3 As shown, after the raw coal enters the feed port 13 of the fluidized bed 15 from the outlet end 11 of the microwave device 5 through the planetary feeder 12, the blower 17 blows the hot air from the hot blast stove 16 (160°C to 220°C, oxygen content 20%) (below) is pressurized and fed into the fluidized bed 15. The fluidized bed 15 is provided with a number of horizontally arranged fluidized chambers 25 separated by partitions 23 and corresponding air inlet branch pipes 24. The hot air passes through the air inlet branch pipes 24 and the air distribution After the plates 20 are evenly distributed, the raw material lignite is fluidized, and moves from the fluidized chamber 25 at the feed end to the fluidized chamber 25 at the discharge end step by step through the partition plate 23, and overflows from the fluidized bed outlet 14 in a granular state. Enter the finished produ...

Embodiment 3

[0031] Another method of the present invention is that the raw material lignite is pre-dried through a microwave device with hot air along the vertical downward direction, and then fluidized and dried through a fluidized bed device with hot air to reduce the free water content of the raw material lignite. to less than 1%.

[0032] The device that the inventive method adopts is vertical, as Figure 4As shown, the solid line arrow in the figure is the movement direction of the raw material lignite, and the dotted line arrow is the movement direction of the hot air. The raw material lignite is generally lignite with a water content of more than 20% and a particle size of less than 10mm. The raw lignite is fed into the microwave device 14' from the feeding port 1', and the rotating shaft 17' of the conveying device rotates at a constant speed under the drive of the motor, and at the same time drives the rake-shaped stirring part 2' and the conical material guide plate 15' fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com