Method for sintering polytetrafluoroethylene

A polytetrafluoroethylene and sintering furnace technology, which is applied in the chemical and chemical industry, can solve the problems of highly toxic, non-wear-resistant polytetrafluoroethylene, affecting product performance, appearance, etc., to achieve good sealing effect, strengthen the sealing effect, The effect of suppressing the evolution of hydrogen fluoride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

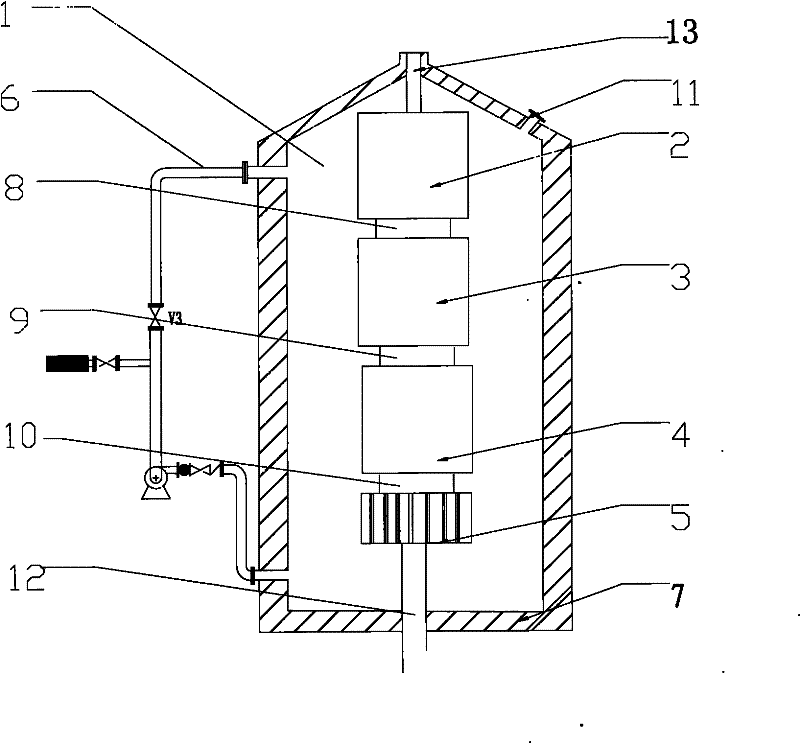

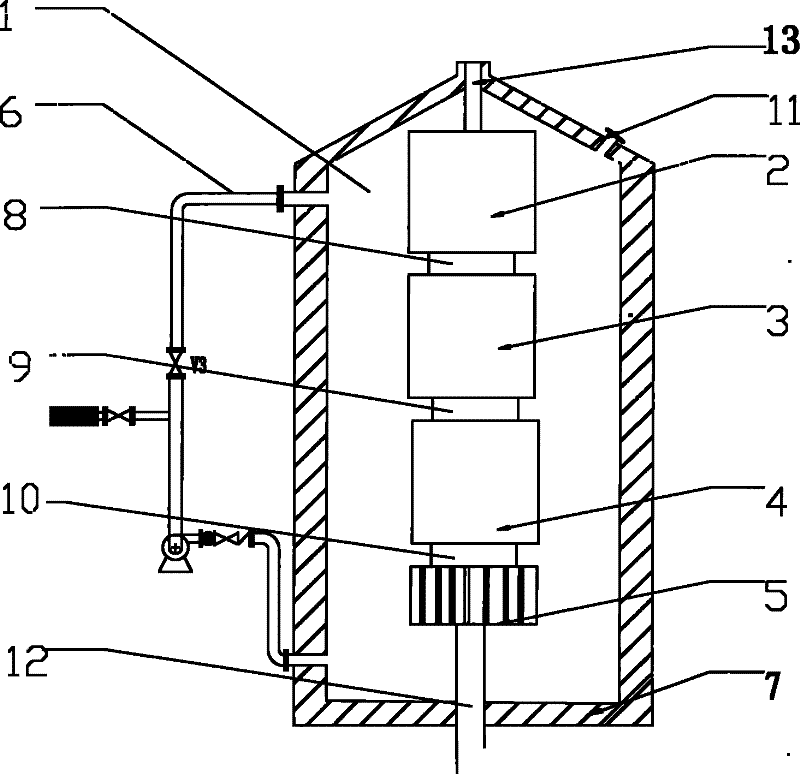

[0028] This embodiment provides a method for sintering polytetrafluoroethylene, which uses a sintering device, see figure 1 ,

[0029] The sintering furnace includes the sintering device including a sintering furnace body (1), a nitrogen delivery device (6), a program control device, and a condenser;

[0030] The sintering furnace body includes four zones: a drying zone (2), a preheating zone (3), a sintering zone (4), and a cooling zone (5);

[0031] The drying zone (2) and the preheating zone (3), the preheating zone (3) and the sintering zone (4), the sintering zone (4) and the cooling zone (5) are each provided with an isolated hearth (8), isolated Furnace (9), isolation furnace (10);

[0032] The program control device includes: a temperature detection and control device, the temperature detection and control device includes: a plurality of temperature sensors, which are respectively installed in the inner drying area (2), preheating area (3), and Sintering zone (4), c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com