Smoke exhaust and ventilation fire resisting damper with high sealing performance

A fire damper, high sealing technology, applied in lift valve, valve details, safety valve and other directions, can solve problems such as thermal deformation, deformation, and processing difficulty for workers, and achieve the effect of improving sealing effect and reducing air leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

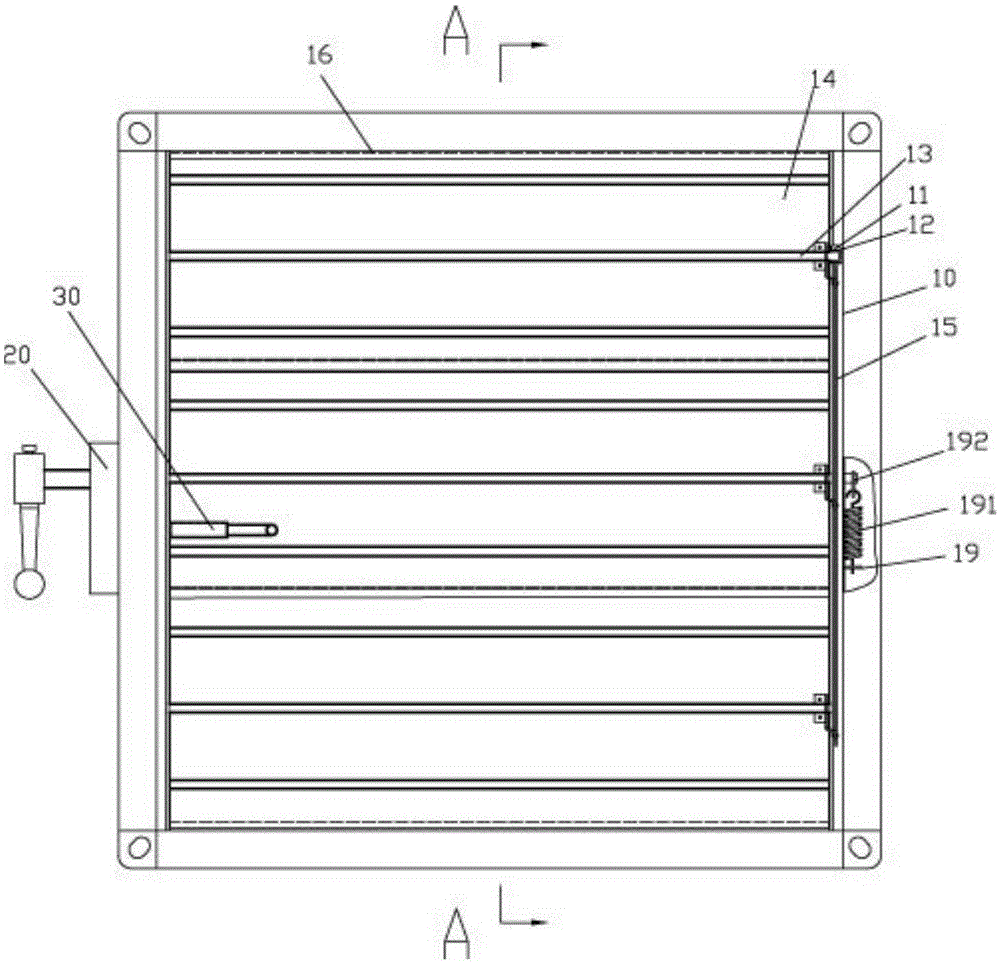

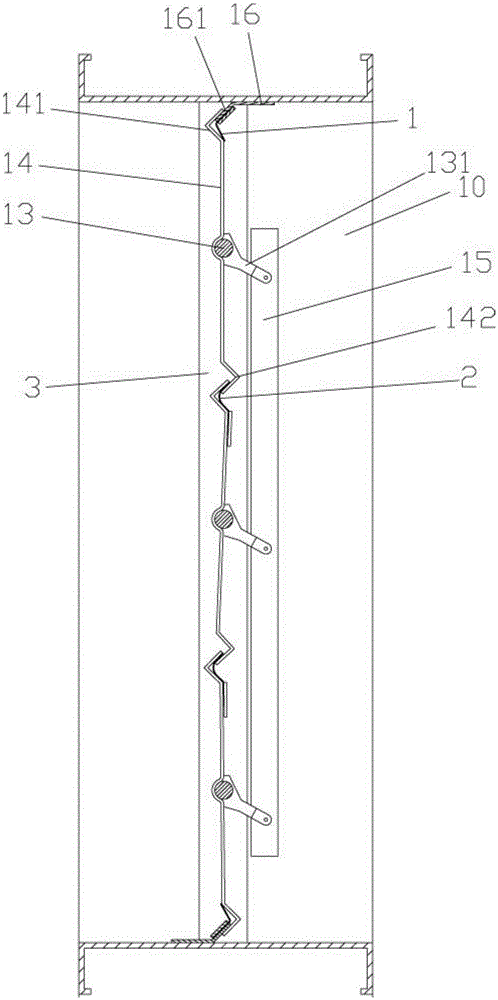

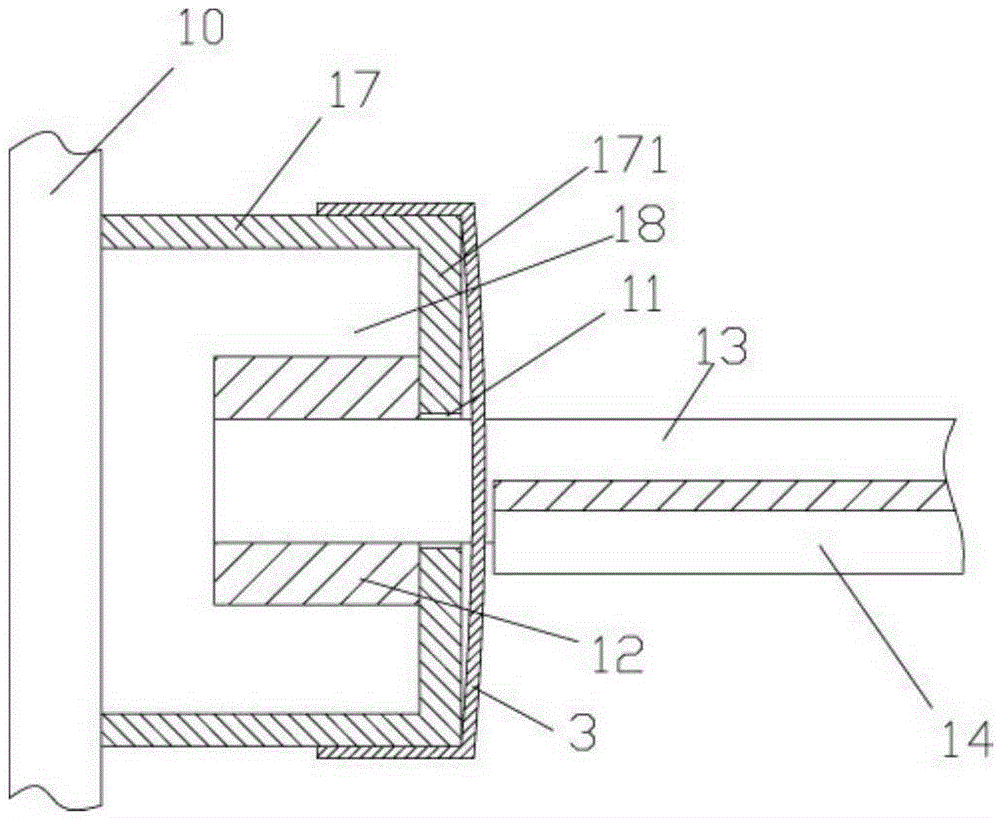

[0025] Examples, see e.g. Figure 1 to Figure 6 As shown, a high-seal smoke exhaust ventilation fire damper includes a valve body 10, and the valve body 10 is provided with an actuator 20, and the actuator 20 is connected with a temperature fuse 30. The left valve inside the valve body 10 The inner side wall and the right inner side wall are provided with a plurality of vane fixing grooves 11, and the left inner side wall or the right inner side wall of the valve body 10 at the vane fixing groove 11 is provided with a vane shaft sleeve 12, and the vane shaft 13 is inserted into the In the corresponding two blade bushings 12, the blade shaft 13 is provided with blades 14, and all the blades 14 are connected by blade connecting rods 15, and the top surface and the bottom surface of the valve body 10 are fixed with windshield strips 16, The windshield strip 16 is a long strip bent into an obtuse angle, one side of the obtuse angle is fixed on the top or bottom surface of the valv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com