Process for production of pigment/resin composition, coloring agent and coloring method

The technology of a resin composition and a manufacturing method is applied in the directions of pigment slurry, developer, organic dye, etc., which can solve the problems of long processing time and poor production efficiency of colorants, and achieves improved production efficiency, shortened heating and kneading time, Excellent dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0087] The following examples are given to illustrate the present invention more specifically, but the present invention is not limited to these examples. It should be noted that "part" or "%" in the text is a quality standard.

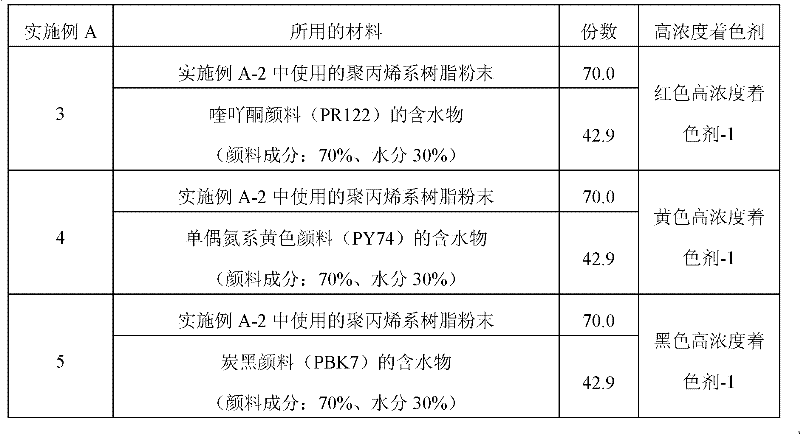

[0088] [Example (1) of colorant for commonly used resins]

Embodiment A-1

[0089] Embodiment A-1 (manufacture of high-concentration colorant and coloring of resin)

[0090] (1) Pigment hydrate (pigment component) obtained by dehydrating copper phthalocyanine blue pigment (C.I. : 88%, moisture: 12%) 34.1 parts and polyethylene resin (ethylene-alpha olefin polymer, melting point is about 60 ° C,) 65.9 parts mixed for 2 minutes, put into the container with 3 exhaust ports with a quantitative feeder In a twin-screw extruder (L / D=52). The temperature of the heater of the twin-screw extruder was gradually set to 60 to 140° C. and set in an inclined manner. After putting in the mixture, let it stand for a period of time, the moisture will be discharged from the downward air outlet close to the input port, and the water vapor will be ejected from the next air outlet. Water vapor is hardly ejected from the exhaust port of the die near the front end of the extruder. The high-concentration colorant extruded from the die is cooled with a cooling water tank an...

Embodiment A-2

[0092] Embodiment A-2 (manufacture of high-concentration colorant and coloring of resin)

[0093] (1) 42.9 parts of a pigment hydrate (pigment component: 70%, moisture: 30%) obtained by removing moisture from an aqueous filter cake of copper phthalocyanine blue pigment (PB15:3) under reduced pressure using a Henschel mixer and 57.1 parts of polypropylene-based resin (polypropylene wax, melting point: about 87° C.) were mixed for 2 minutes, and injected into a twin-screw extruder (L / D=52) having three vents with a quantitative feeder.

[0094] The temperature of the heater of the twin-screw extruder was gradually set to 60 to 140° C. and set in an inclined manner. After putting in the mixed material, leave it for a period of time, the moisture will be discharged from the downward air outlet close to the input port, and the water vapor will be ejected from the next air outlet. Water vapor is hardly ejected from the exhaust port of the die near the front end of the extruder. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com