Method for manufacturing flexible optical plates, and flexible optical plate manufactured by utilizing same and backlight module

A manufacturing method and backlight module technology, applied in the direction of optics, optical components, semiconductor devices of light-emitting components, etc., can solve problems such as excessive processing size, processing defects, and inability to reach the processing size, so as to improve quality and accuracy, The effect of reducing manufacturing and equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The aforementioned and other technical content, features and effects of the present invention are described in detail in conjunction with the accompanying drawings.

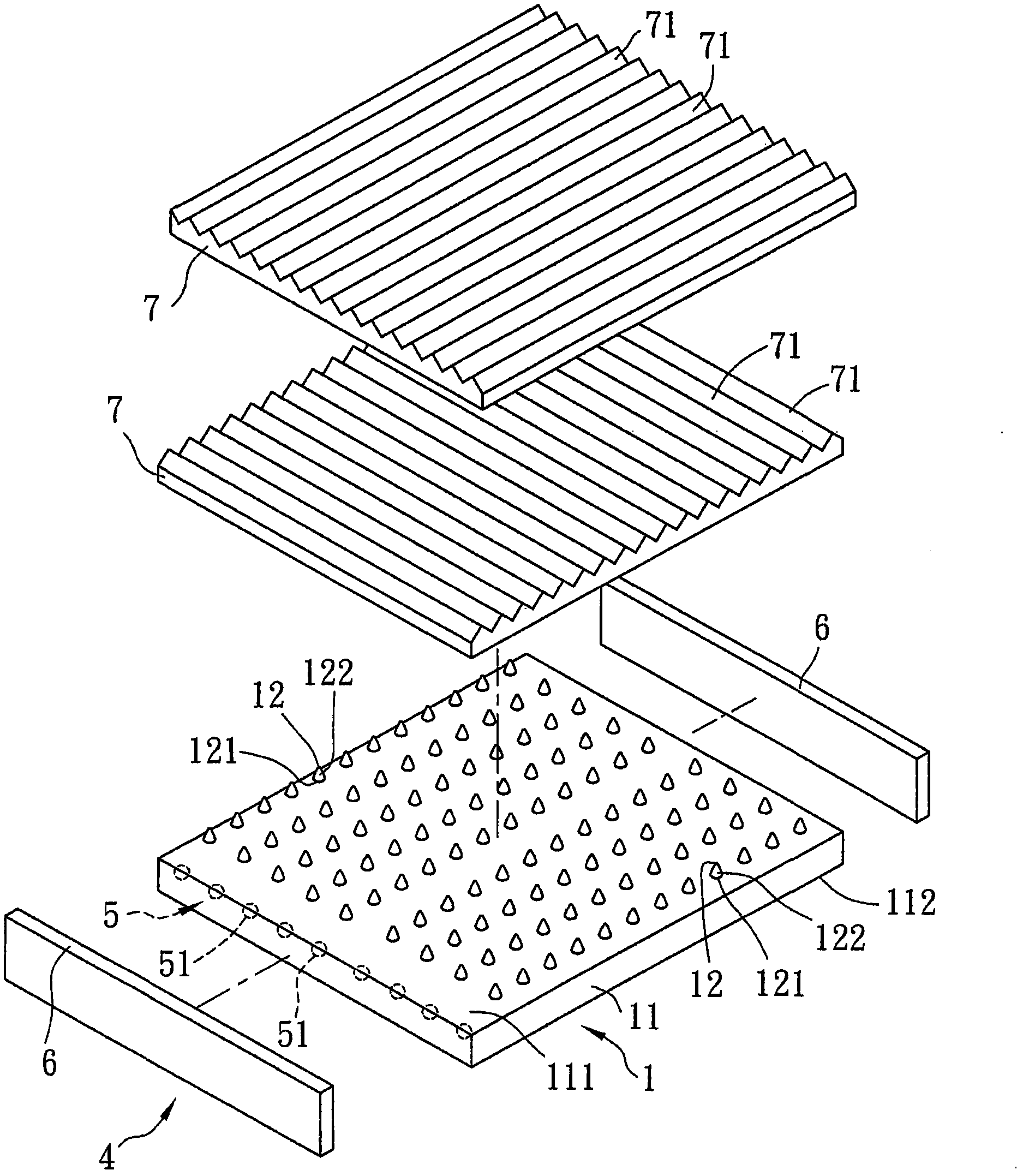

[0035] refer to figure 1 , 2 , is a preferred embodiment of the backlight module 4 of the present invention, which can be used to provide a uniform planar light source for a display panel (not shown in the figure). The backlight module 4 includes: a flexible optical plate 1 , a light emitting unit 5 , two reflective plates 6 and two brightening sheets 7 each having a plurality of prism structures 71 arranged in parallel.

[0036] The flexible optical plate 1 is used as a light guide plate in this embodiment, and it includes a base material 11 and several microstructures 12 located on the base material 11 . Wherein, the substrate 11 has a first light-transmitting surface 111 and a second light-transmitting surface 112 spaced apart from the first light-transmitting surface 111 . The microstructures 12 pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com