High-strength high-heat-resistance copper alloy

A high heat resistance, copper alloy technology, applied in the direction of electrical components, circuits, electric solid devices, etc., can solve the problems of reduced heat resistance, difficulty in obtaining, high strength, etc., and achieves improved smoothness, strength and heat resistance. , the effect of improving hot workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

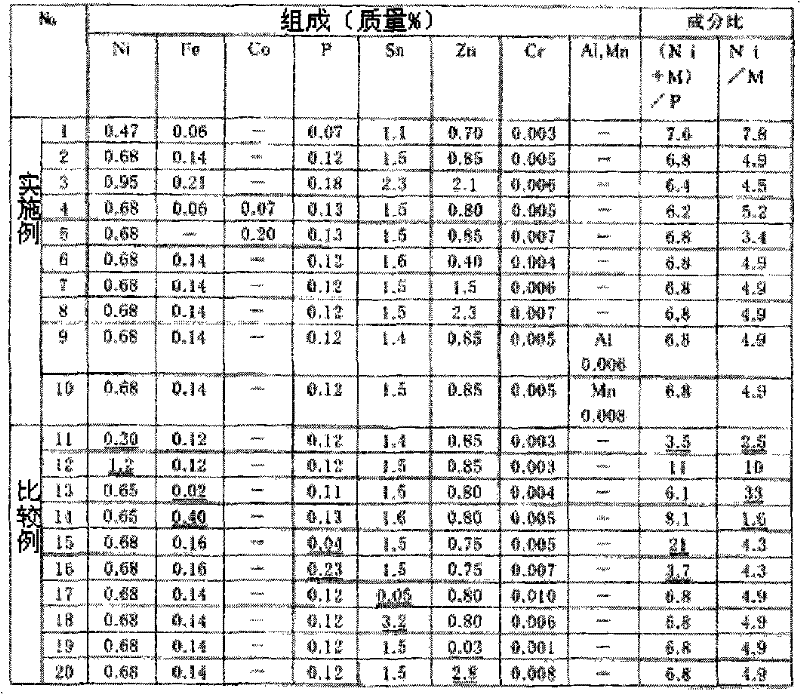

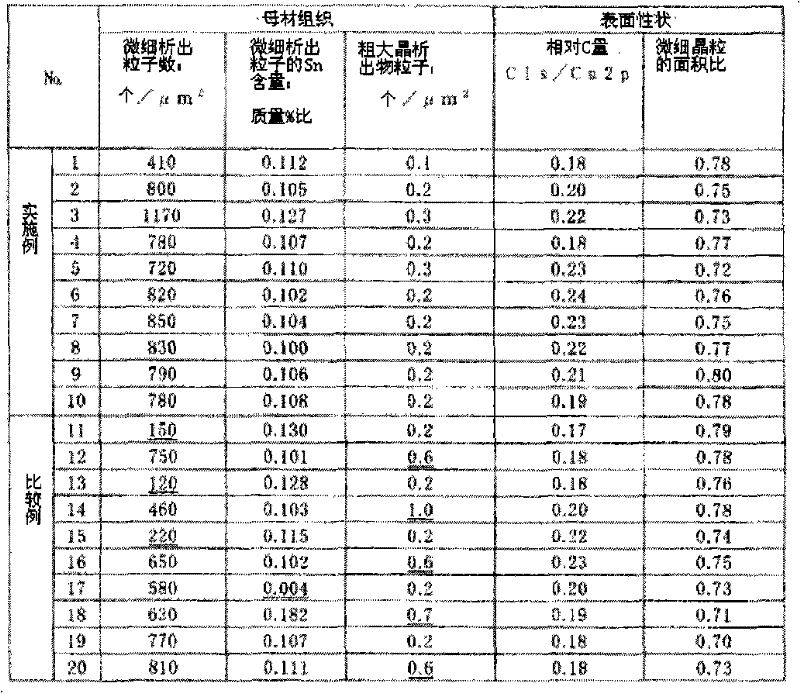

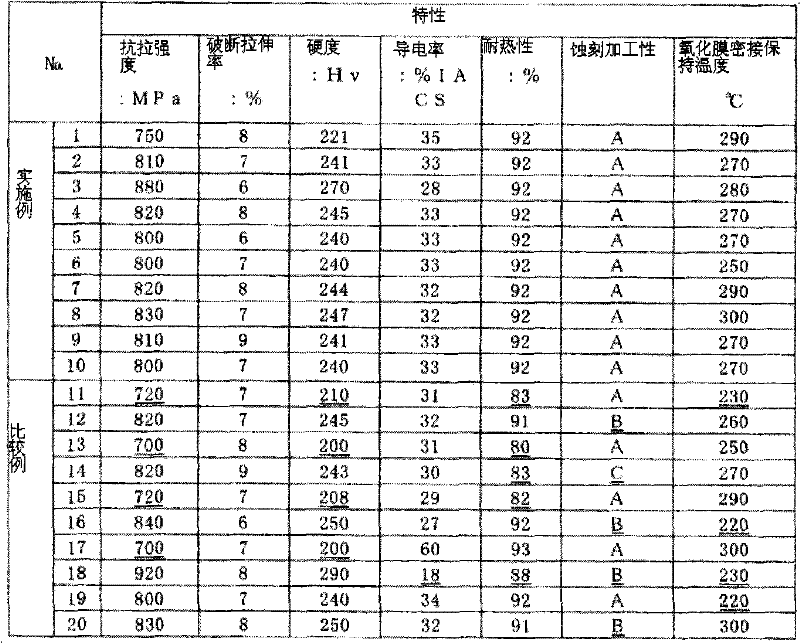

[0083] Next, experimental results of Examples and Comparative Examples capable of demonstrating the effects of the present invention will be described. As a method of manufacturing a copper alloy plate, after melting a copper alloy melt having the composition shown in Table 1 below in a high-frequency furnace, it is poured into a graphite-made book (book) mold to obtain a thickness of 50 mm and a width of 50 mm. 200mm ingot with a length of 200mm. After the ingot is solidified in the mold, it is water-cooled from a temperature of 700 to 800°C. In addition, the casting mold made of graphite has sufficient heat capacity and thermal conductivity, and the cooling rate at the time of solidification obtained from the secondary branch interval between dendrite arms is 1° C. / sec or more. In addition, the copper alloys shown in Table 1 contain elements such as Si, Ti, Zr, Be, V, Nb, Mo, W, and Mg in a total amount of 0.01% by mass or less as unavoidable impurities. Contains elements ...

Embodiment 2

[0114] Next, the experimental results of the relationship between the surface properties and the oxide film adhesion maintenance temperature will be described. In this Example 2, a copper alloy plate having a thickness of 0.2 mm was obtained from the ingot of Example 2 in Table 1 by the same method and conditions as in Example 1. Therefore, the characteristics of composition, composition ratio, base metal structure, tensile strength, general elongation, hardness, electrical conductivity, heat resistance, and etchability are the same as those of Example 2 in Table 3.

[0115] However, the annealing is twice annealing and low temperature annealing, and, in N 2 +10%H 2 atmosphere (dew point: below -20°C, O 2 Concentration: 50ppm or less), changing the cleaning treatment before and after annealing, thereby changing the surface properties (relative C content, area ratio of fine crystal grains) of the copper alloy sheet, and evaluating the oxide film adhesion maintenance temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com