Instrument and method for measuring secondary clamping deviation during numerical control machining based on image technology

A technology of secondary clamping and deviation measurement, applied in measuring devices, metal processing equipment, measuring/indicating equipment, etc., it can solve the problem that the operator's technical level is also very high, the efficiency and accuracy are reduced, and the deviation value error is very large, etc. problems, to achieve the effect of fast and accurate measurement methods, improve processing accuracy and processing efficiency, and maintain continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

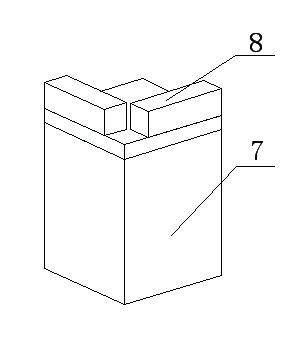

[0027] An installation method of a secondary clamping deviation measuring instrument for NC machining based on image technology. The measuring instrument is divided into two parts: the first part is composed of a camera and a digital signal processor DSP, and the second part is the shooting object. The shooting object is specially made The special measuring target, the base material of the special measuring target is 45 steel, and the upper surface is equipped with a red light-emitting diode LED lamp tube; Carve out an accurate reticle for shooting and measurement. The size of the red rectangular frame is 10.00mm×10.00mm; one X and one Y-direction level are installed on the reticle layer.

Embodiment 2

[0029] A measurement method of a secondary clamping deviation measuring instrument for NC machining based on image technology, the specific measurement method is as follows:

[0030] After installing the fixture and workpiece for the first time, install the camera on the main shaft through the tool system matching the main shaft of the machine tool to ensure a high coaxiality between the camera and the tool holder; operate the machine tool to move the camera to the origin of the processing program, that is, special measurement Directly above the target, adjust the Z-axis coordinates to H, record the X and Y-axis coordinates, and shoot; use the image processing method described below to process the captured images, and at the same time perform system calibration, measure and calculate the distance between the center of the cross and the center of the image For the actual deviation value, input the deviation value into the machine tool system, and adjust the position of the camer...

Embodiment 3

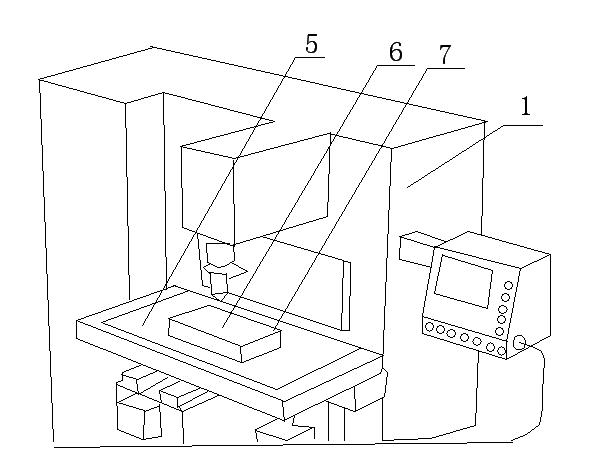

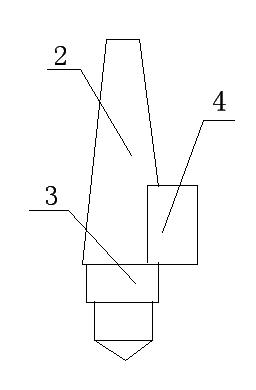

[0034] An image technology-based CNC machining secondary clamping deviation measuring instrument, which consists of: a bed body 1, the bed body 1 is equipped with a fixed handle 2, and the fixed handle 2 is connected to a camera 3 and an image processor DSP4 , the bed body 1 has a workbench 5, a workpiece holder 6 is placed on the workbench 5, a special measurement target 7 is placed on the workpiece holder, and the special measurement target 7 is connected to a horizontal Foot 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com