Method for increasing yield of volvariella volvacea

A technology for straw mushrooms and strains, which is applied in the field of increasing the production of straw mushrooms, can solve problems such as many impurities, and achieve the effects of high income, reduced pollution rate and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of cultivation raw materials

[0037] Cultivation raw materials are mostly waste cotton, cottonseed hulls or, wheat straw, rice straw, corn stalks. The main raw materials of the formula are 50% cotton waste + 40% straw + 10% bran and an appropriate amount of lime. For waste cotton, it is best to choose fresh, dry, moldy and rot-free raw materials. It is best to expose to the sun for 1-2 days to kill the eggs. Straw is cut into the small section that is less than 5cm.

[0038] (2) Weighing

[0039] Weigh the ingredients according to the ratio of the above raw materials, then mix the raw materials evenly, and put them in the large pool of mixing materials.

[0040] (3) Soak raw materials

[0041] Soak the raw materials with 1% lime water, step on it while pouring water, until all the raw materials are soaked. Adjust the pH value of the compost to around 9 and test it with pH test paper. Control the water content at about 65-68% (grab the material wi...

Embodiment 2

[0060] Taking the straw mushroom strain V23 as an example,

[0061] Prepare raw materials according to (1).

[0062] Weigh according to (2).

[0063] Soak the ingredients according to (3).

[0064] According to (4) culture material pre-fermentation.

[0065] Add sodium citrate according to (5).

[0066] Enter the room according to (6) culture material.

[0067] Post-fermentation according to (7) compost.

[0068] Seed according to (8).

[0069] Manage according to (9) mycelial growth stage.

[0070] Manage according to (10) fruiting stage.

[0071] Harvest according to (11).

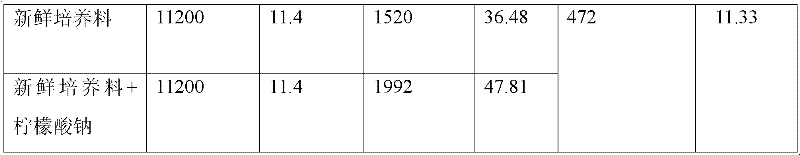

[0072] According to 50% waste cotton + 40% straw + 10% bran and appropriate amount of lime, weigh the cultivation raw materials, add water and stir evenly after mixing, and add carbon source accounting for 0.02840% of the wet weight of the culture material. The water volume is 65-68%, build a heap, and cover the film for natural fermentation for 2 days, after which the culture material enters th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com