Multifunctional microfluid control device for operating biochemical fluids in microfluid control chip automatically

A technology of microfluidic chip and microfluidic device, which is applied in the direction of biological testing, material inspection, etc., can solve the problems of high cost, dead volume, low conductivity, etc., and achieve the effect of small error range and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

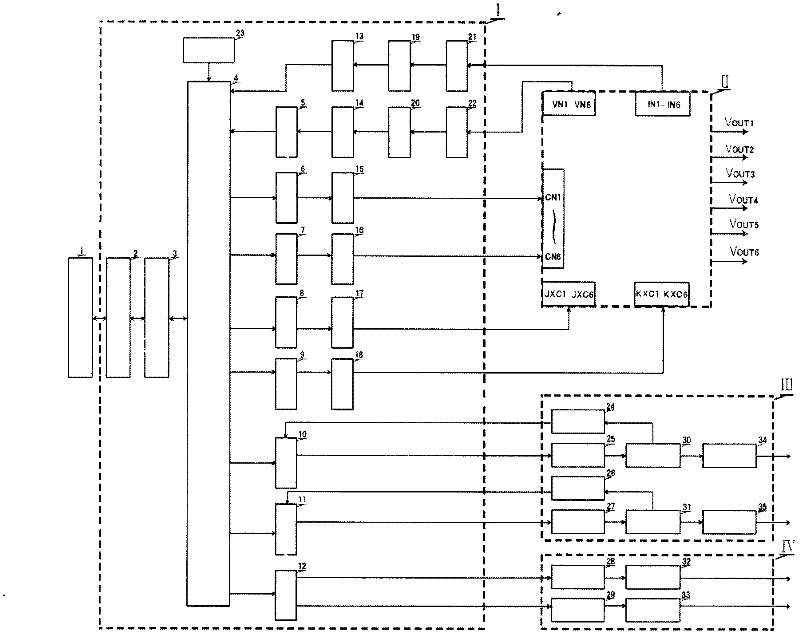

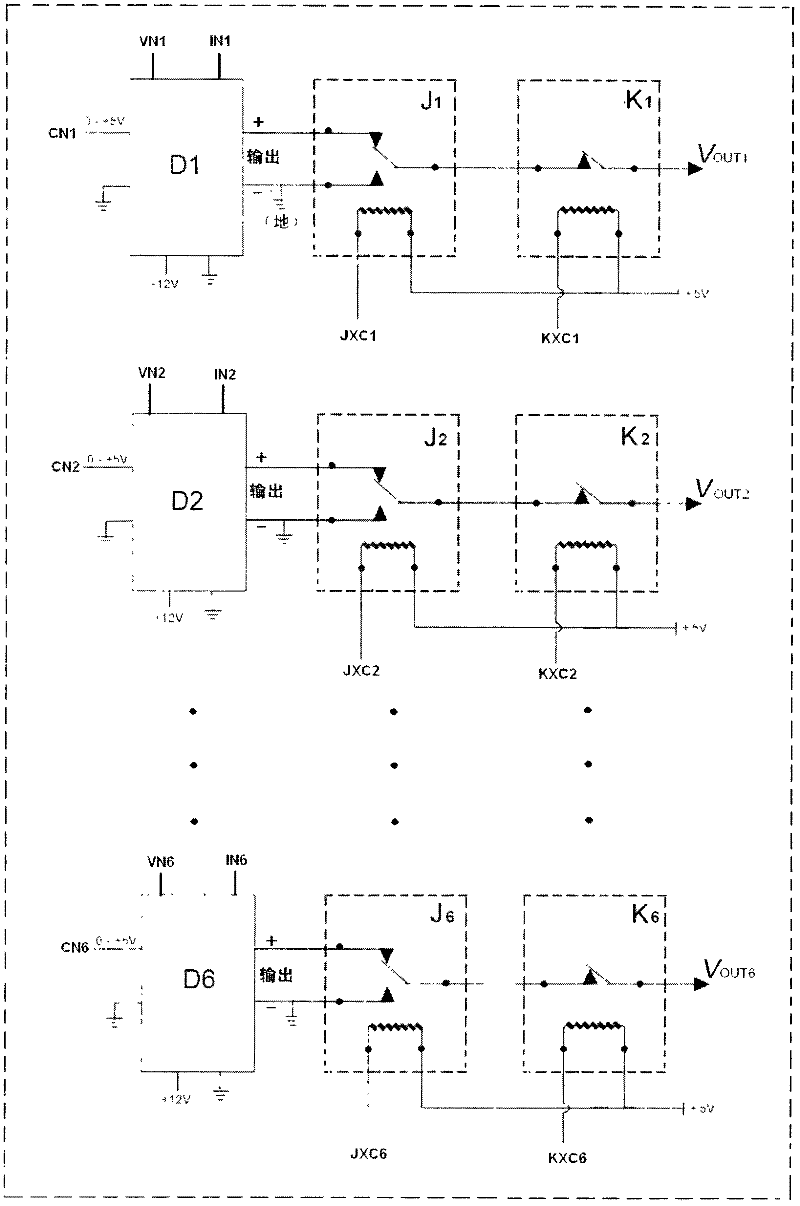

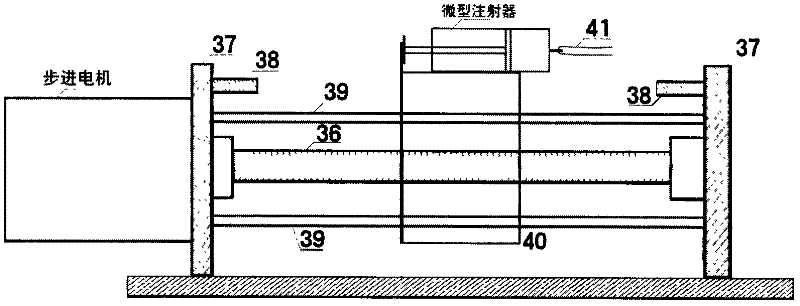

[0057] It consists of a system control module I, an electric drive module II, a hydraulic drive module III, a dielectrophoresis module IV and program software, wherein: the system control module I uses a single-chip microprocessor 4 as the control core, and the The electric drive module II is a six-way DC high voltage, the hydraulic drive module III is a two-way micro-injection pump, the dielectrophoresis module IV is a two-way sine wave, and the program software is controlled by a time period.

[0058] The single-chip microprocessor 4:

[0059] Connect to the serial port of PC 1 through logic level conversion 3 and digital communication interface 2; connect to the input terminals of two parallel analog signal conditioning circuits 15 and 16 through two parallel digital-to-analog conversion circuits 6 and 7 respectively ; Through two parallel serial shift registers 8,9 are respectively connected with the input terminals of two parallel power expansion circuits 17,18; the outpu...

Embodiment 2

[0070] combined with figure 1 , 2 , 3 further describe in detail the combined connection between each module of the present invention and each device in each module:

[0071]PC machine 1 is the PC machine that program software of the present invention has been installed, and PC machine is responsible for functions such as data collection, storage, display / record, single-chip microprocessor management and interface operation. The digital communication interface 2 and the logic level conversion 3 are used for two-way data communication between the PC and the single-chip microprocessor 4 . The single-chip microprocessor is an enhanced micro-power consumption 8-bit single-chip microprocessor ATmega16-16PC produced by ATMEL. The ATmega16-16PC has 16K bytes of programmable Flash, 512 bytes of EEPROM, 1K bytes of SRAM, and 32 1 general-purpose I / O ports, 32 general-purpose working registers, 3 timers / counters (T / C), on-chip / external interrupts, UART serial communication ports (TXD,...

Embodiment 3

[0079] Embodiment 3: Further describe the working process of the present invention applied to microfluidic chip biochemical analysis:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com