Resource recycling process for nickel-containing sludge in electroplating enterprises

A resource and sludge technology, applied in sludge treatment, nickel oxide/nickel hydroxide, water/sludge/sewage treatment, etc., can solve waste of resources, pollute the environment, and nickel-containing sludge cannot be recycled and utilized and other issues to achieve the effect of reducing pollution, low energy consumption and realizing value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: A resource recovery process of nickel-containing sludge in electroplating enterprises

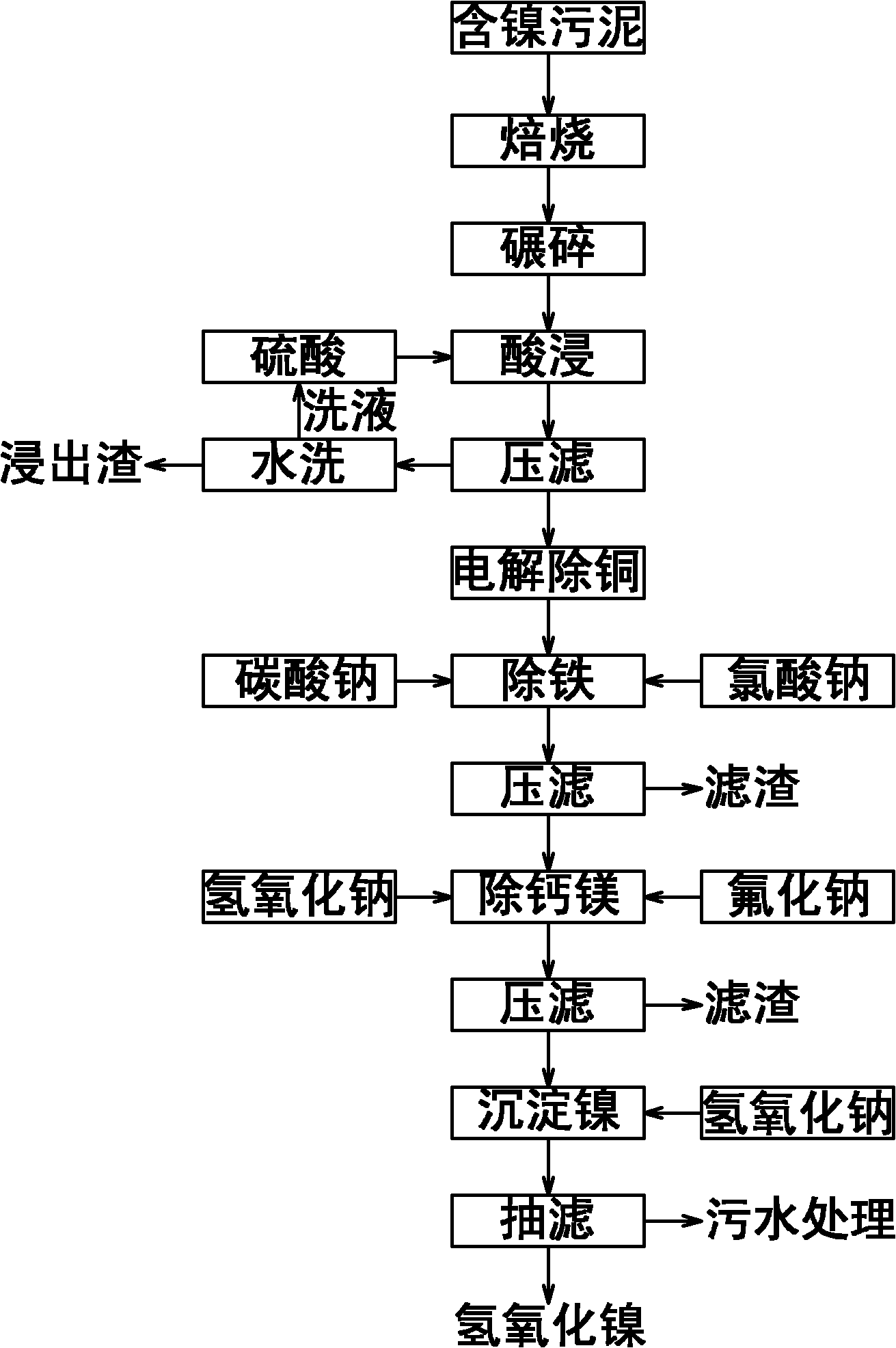

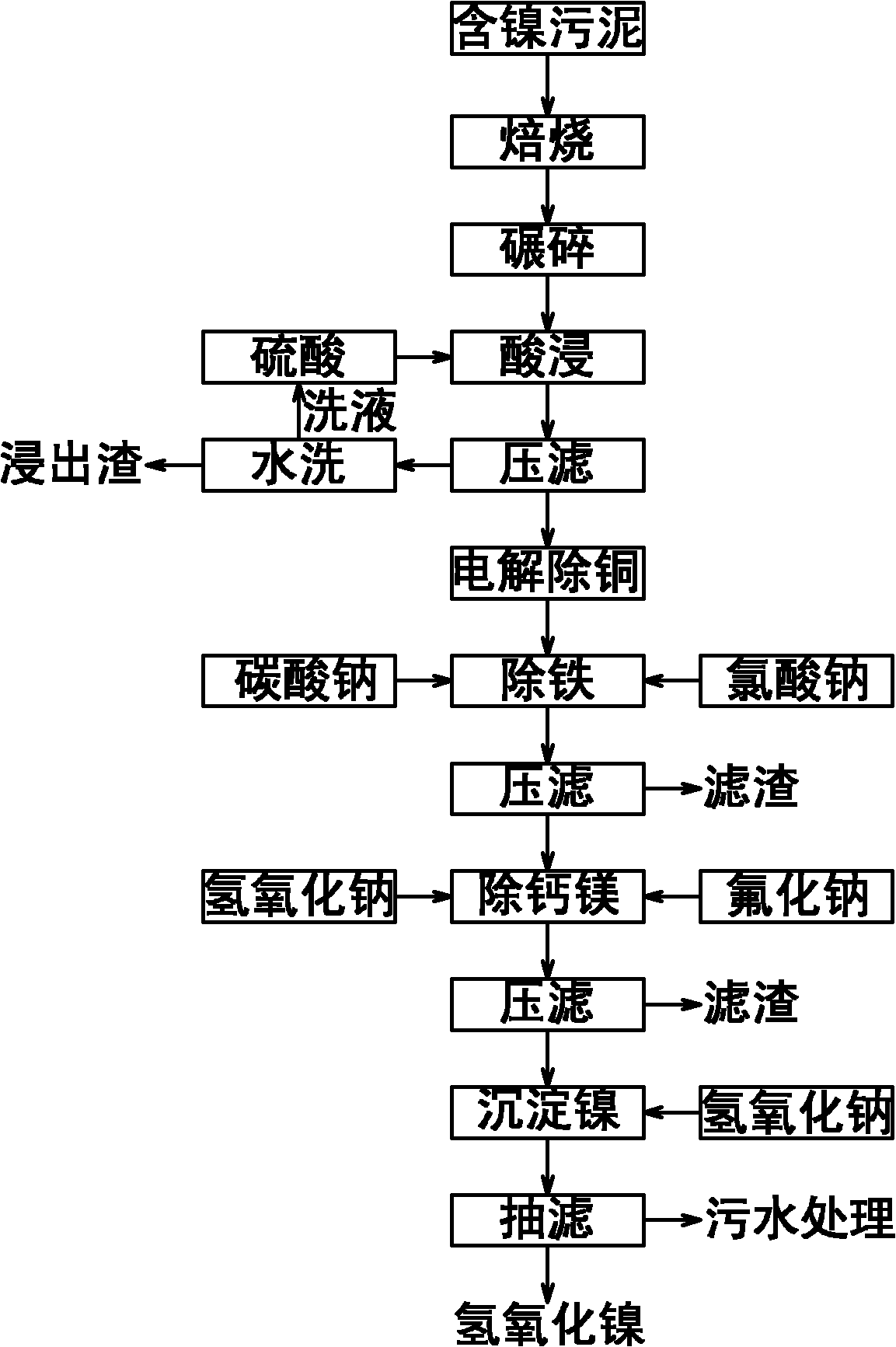

[0031] see attached figure 1 As shown, a resource recovery process of nickel-containing sludge in electroplating enterprises, the specific steps are as follows:

[0032] (1) Roasting and purification

[0033] The water content of nickel-containing sludge after pressure filtration is 73%, and the sludge also contains a small amount of organic matter. The sludge is roasted in the roasting furnace, the roasting temperature is controlled to be 600-700 °C, and the roasting time is 6 hours. After roasting, the water and organic matter can be burned off, and the water can be basically completely burned off. The organic matter lost by burning accounts for the dry basis of the sludge. about 30% of the weight. After the sludge is roasted, it can effectively reduce the moisture and organic matter in the sludge, realize the reduction of the sludge, and reduce the amount of chemi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com