Low-molecular carbon-free polysilazane and liquid-phase synthesis method thereof

A carbon polysilazane, liquid phase synthesis technology, applied in silicon compounds, chemical instruments and methods, nitrogen and non-metallic compounds, etc., can solve problems such as adverse effects on electrical properties of materials, and achieve low price and good controllability. , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

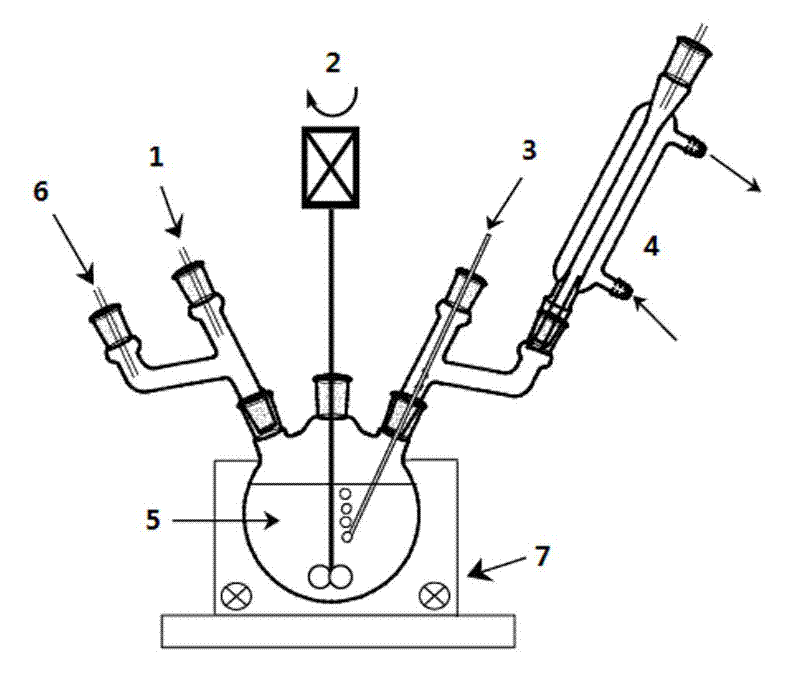

[0029] (1) Check the airtightness of the synthesis device, fully dry the whole device, evacuate, fill the container 5 with nitrogen through the inert gas branch pipe 6, and repeat the process three times to replace the air in the container 5;

[0030] (2) Add tetrahydrofuran and trichlorosilane to container 5 through silicon source raw material inlet pipe 1, wherein tetrahydrofuran is excessive; start agitator 2 to stir, so that trichlorosilane is completely dissolved in tetrahydrofuran;

[0031] (3) Start the condenser 4, pass excess ammonia gas into the container 5 through the nitrogen source raw material inlet pipe 3, heat the container 5 to 60°C through the temperature-controlled water bath 7, and let it stand for 3 hours. After the reaction is completed, protect it in an inert atmosphere Filtration to obtain a clear solution;

[0032] (4) Distill under reduced pressure at room temperature to remove the solvent tetrahydrofuran to obtain a transparent liquid, which is the c...

Embodiment 2

[0035] (1) Same as step (1) of Example 1;

[0036] (2) Add pyridine and dihydrodichlorosilane to container 5, where pyridine is excessive; start stirrer 2 for stirring;

[0037] (3) Start the condenser 4, pass excess ammonia gas into the container, let it stand at room temperature for 6 hours, and the reaction ends; filter under the protection of an inert atmosphere to obtain a clear solution;

[0038] (4) Distill under reduced pressure at normal temperature or under heating conditions to remove the solvent pyridine to obtain a transparent liquid, namely the carbon-free polysilazane of the present invention. The yield is about 70%.

[0039] The dielectric constant of the pyrolysis product of the carbon-free polysilazane synthesized in this example (ie silicon nitride ceramic) is 3.3.

Embodiment 3

[0041] (1) Same as step (1) of Example 1;

[0042] (2) Add triethylene glycol dimethyl ether and monochlorosilane to the container 5, wherein the solvent triethylene glycol dimethyl ether is excessive; start the agitator 2 for stirring;

[0043] (3) Start the condenser 4, pass excess hydrazine into the container 5, heat to 100°C, let it stand for 1 hour, and the reaction ends; filter under the protection of an inert atmosphere to obtain a clear solution;

[0044] (4) Distill under reduced pressure at normal temperature or under heating conditions to remove the solvent pyridine to obtain a transparent liquid, namely the carbon-free polysilazane of the present invention. The yield is about 75%.

[0045] The dielectric constant of the pyrolysis product of the carbon-free polysilazane synthesized in this example (ie silicon nitride ceramic) is 3.6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com