Hydrophobic ceramic hollow fiber membrane applied to membrane distillation and preparation method thereof

A technology of fiber membrane and hydrophobicity, which is applied in the field of preparation of hydrophobic ceramic hollow fiber membranes, can solve the problems of low packing density of membrane modules, low distillation separation efficiency of unit system, and small membrane flux, etc., and achieve long service life, Good high temperature resistance and low mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a method for preparing a hydrophobic ceramic hollow fiber membrane used for membrane distillation, comprising the following steps:

[0036] a) mixing ceramic powder, polyethersulfone, N-methyl-1-pyrrolidone and a dispersant, and grinding to obtain a slurry;

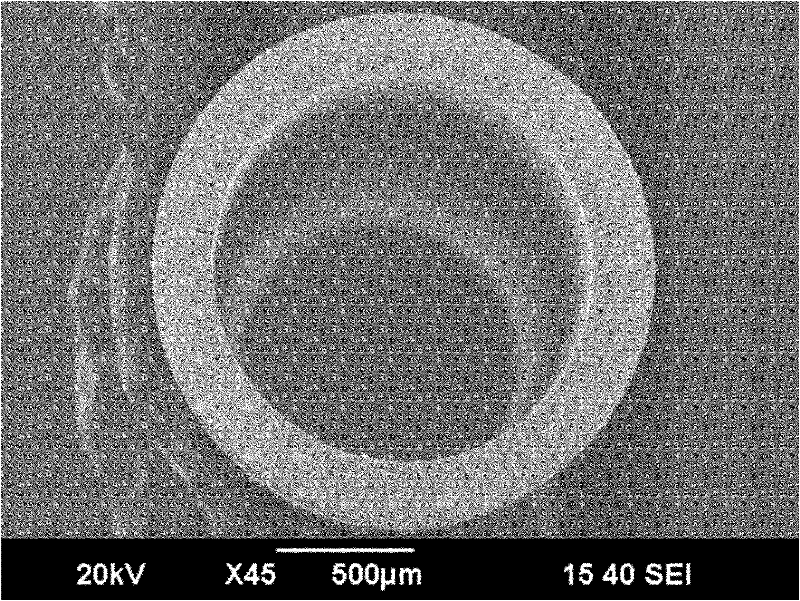

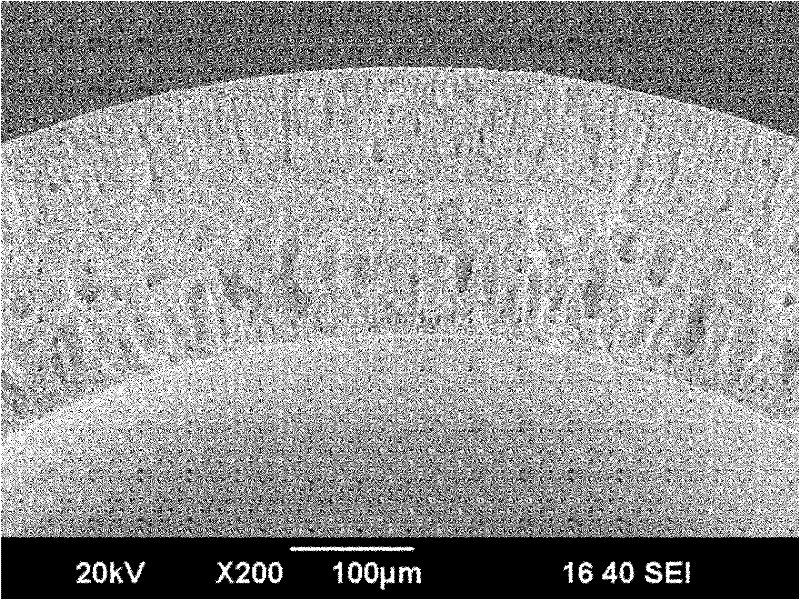

[0037] b) extruding the slurry through a spinneret, and obtaining a hollow fiber green body after phase inversion molding;

[0038] c) sintering the hollow fiber body to obtain a ceramic hollow fiber membrane;

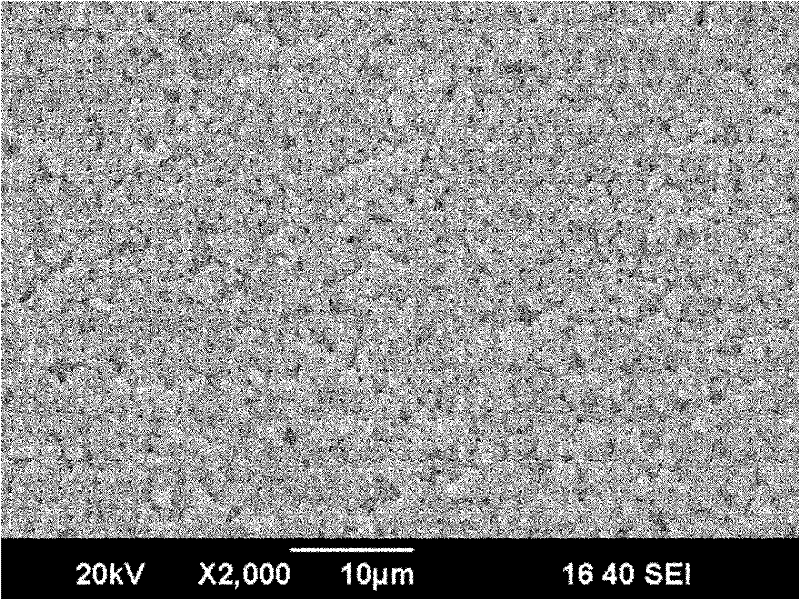

[0039] d) modifying the ceramic hollow fiber membrane with silane as a modifier to obtain a hydrophobic hollow fiber membrane.

[0040] In the present invention, ceramic powder, polyethersulfone, N-methyl-1-pyrrolidone and dispersant are used as raw materials, and a ceramic hollow fiber membrane matrix is prepared by a wet phase inversion method, and then the surface of the ceramic hollow fiber membrane matrix is treated. Hydrophobic treatment to obtain a ceramic hollow fiber me...

Embodiment 1

[0060] Mix 10g of polyvinylpyrrolidone, 70g of polyethersulfone, 350g of N-methyl-1pyrrolidone and 570g of alumina powder with an average particle size of 0.7μm and ball mill for 48 hours to obtain a uniform and stable slurry. Gas 30min;

[0061] A spinneret consisting of two concentric tubes with an interlayer gap of 1.0 mm and an inner tube hole diameter of 2.0 mm is used as an extrusion die, and the slurry is extruded through the interlayer gap of the spinneret under a pressure of 0.05 MPa At the same time, under the pressure of 0.02MPa, tap water at 25°C is extruded from the inner tube hole, and the extrudate extruded from the interlayer gap enters tap water at room temperature, undergoes phase inversion solidification molding, and obtains a hollow fiber blank;

[0062] Sintering the hollow fiber body at 1550°C for 15 hours to obtain a ceramic hollow fiber membrane;

[0063] Dissolve 2g of tridecafluorooctyltriethoxysilane in 100g of ethanol, stir evenly, add 2g of water,...

Embodiment 2

[0071] 10g of polyvinylpyrrolidone, 60g of polyethersulfone, 300g of N-methyl-1pyrrolidone and 630g of 3% yttria-stabilized zirconia powder with an average particle size of 0.6 μm were mixed and ball milled for 48 hours to obtain a uniform and stable slurry. Described slurry vacuum degassing 30min;

[0072] A spinneret consisting of two concentric tubes with an interlayer gap of 1.0 mm and an inner tube hole diameter of 2.0 mm is used as an extrusion die, and the slurry is extruded through the interlayer gap of the spinneret under a pressure of 0.05 MPa At the same time, under the pressure of 0.02MPa, tap water at 25°C is extruded from the inner tube hole, and the extrudate extruded from the interlayer gap enters tap water at room temperature, undergoes phase inversion solidification and molding, and obtains a ceramic hollow fiber body;

[0073] Sintering the ceramic hollow fiber body at 1450° C. for 15 hours to obtain a ceramic hollow fiber membrane;

[0074] Dissolve 2g of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com